Whole-plane EMI filter integrated structure composed of round-plane PCB coupling inductors

A technology of coupled inductors and filters, which is applied in the field of full planar magnetic integration structures, can solve problems that do not conform to the development trend of filter miniaturization, affect filter reliability, and increase filter volume, and achieve volume reduction, Improved power density and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

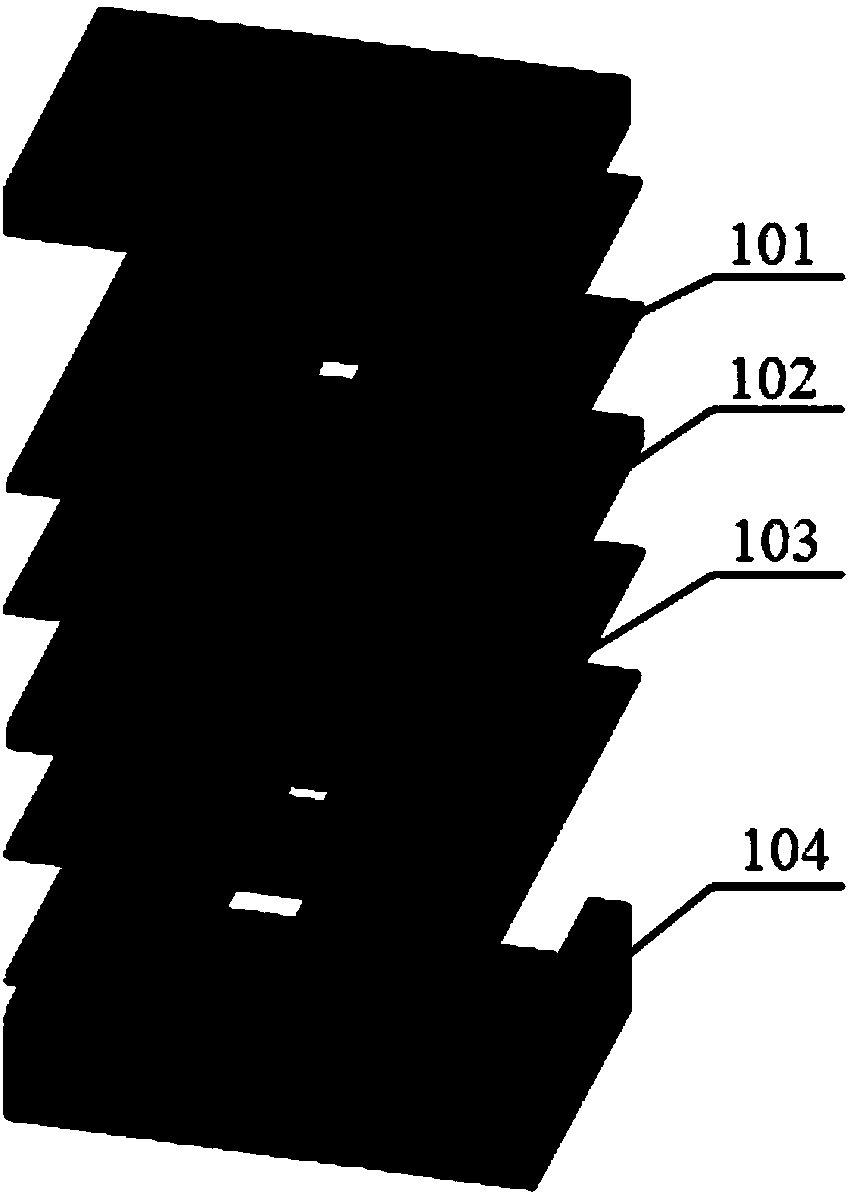

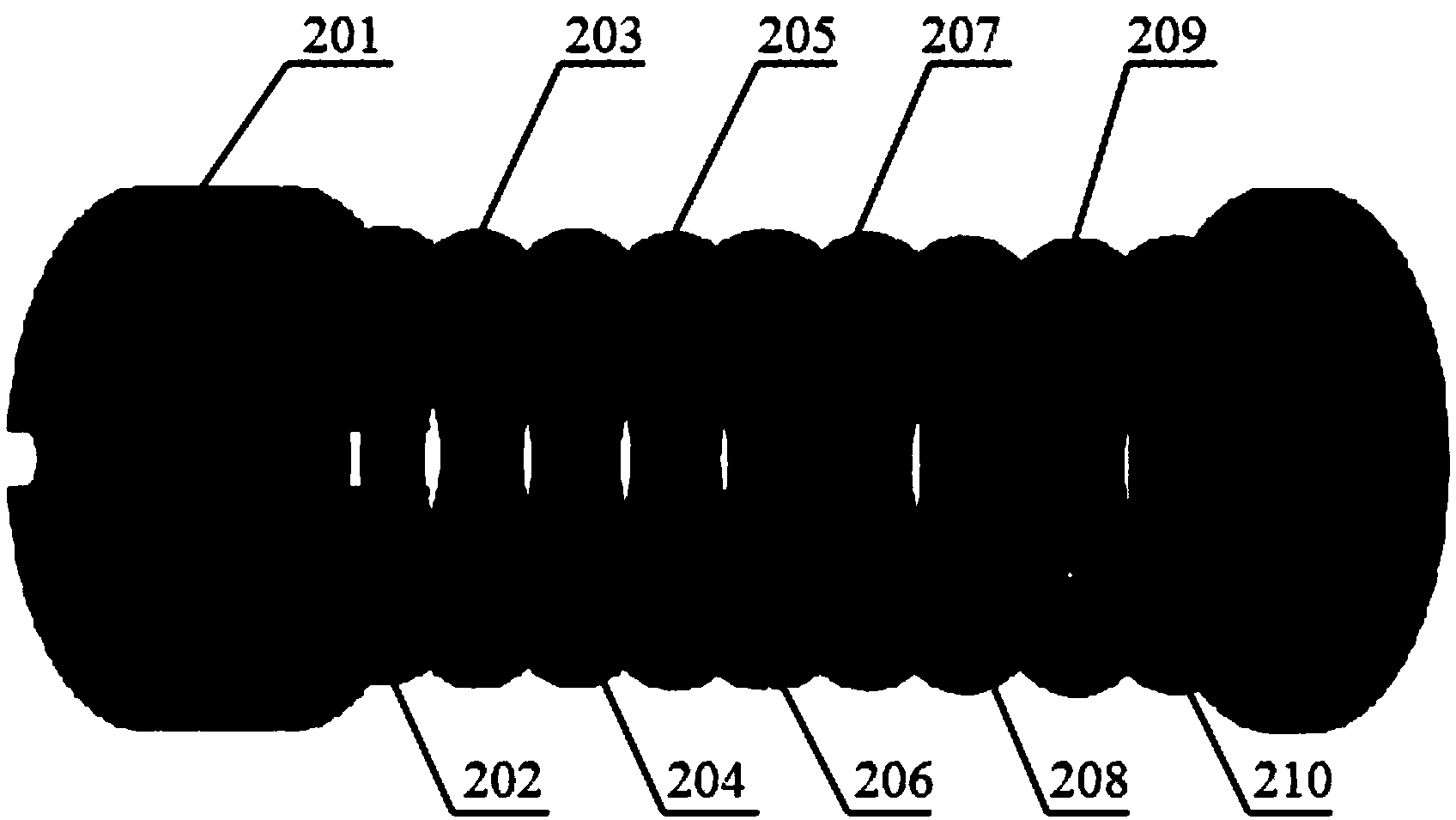

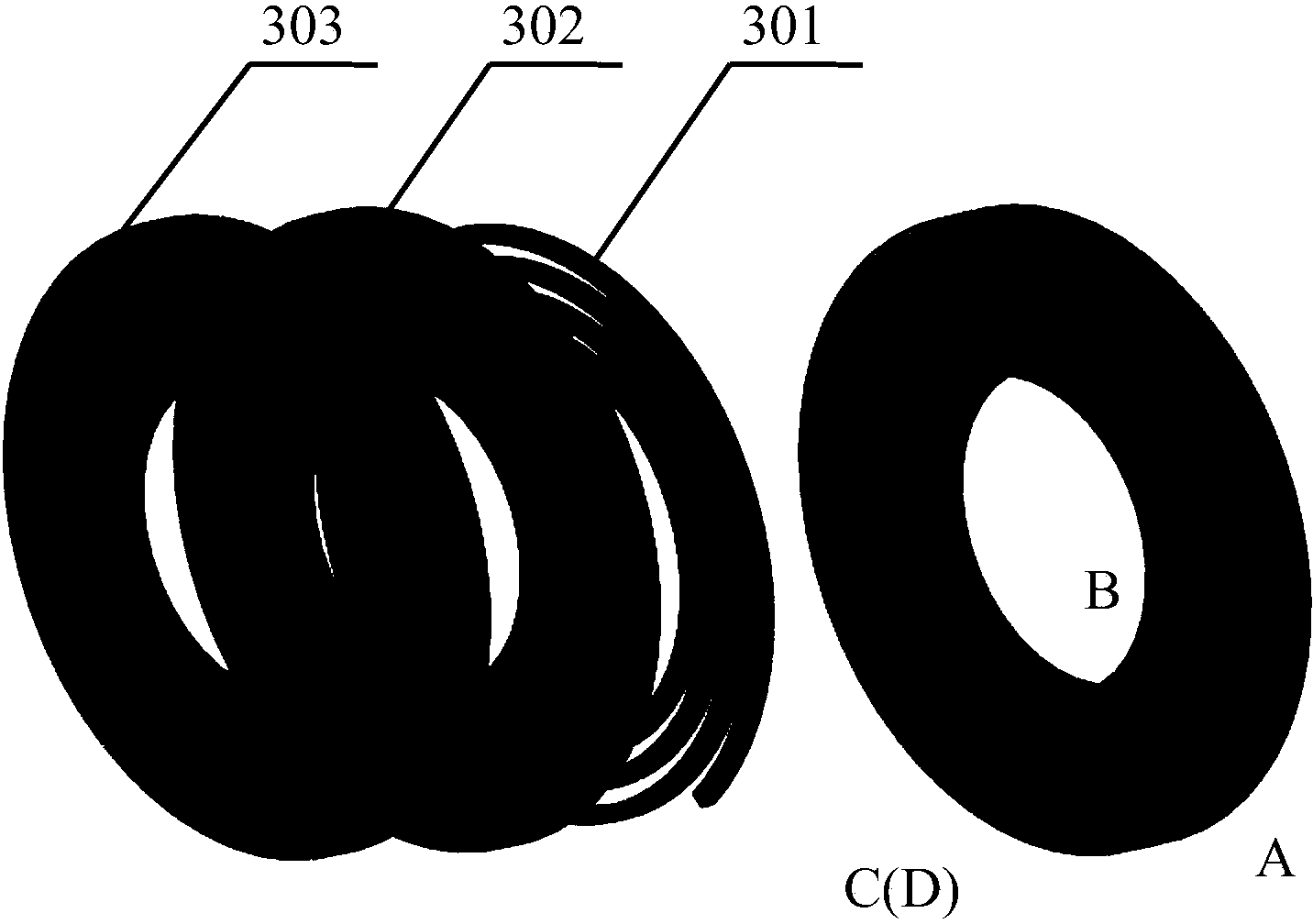

[0027] Such as Figure 6A As shown, the present invention provides a fully planarized EMI filter integrated with circular planar PCB coupled inductors. The structure includes a circular planar PCB coupling inductor 601 and its leakage inductance acting as a common-mode inductor and a differential-mode inductor respectively, a differential-mode integrated capacitor I602 and a differential-mode integrated capacitor II610, a common-mode integrated LC unit I605 and a common-mode integrated LC unit II607 . Wherein the circular planar PCB coupling inductor 601 (such as Figure 4A shown) includes a PCB substrate (the material is FR-4), a circular ceramic planar magnetic core 401 embedded on the PCB substrate, and a PCB printed wire 402, wherein the PCB printed wire 402 includes two, and one of the PCB The two ends of the printed wire 402 are respectively E ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com