Method for producing organic sacchariferous straw feed

A production method and technology of saccharified grass, applied in the field of organic saccharified grass feed production, can solve the problems of high cost of organic beef and mutton and organic milk, and achieve the effects of strengthening fattening effect, improving quality and raising feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

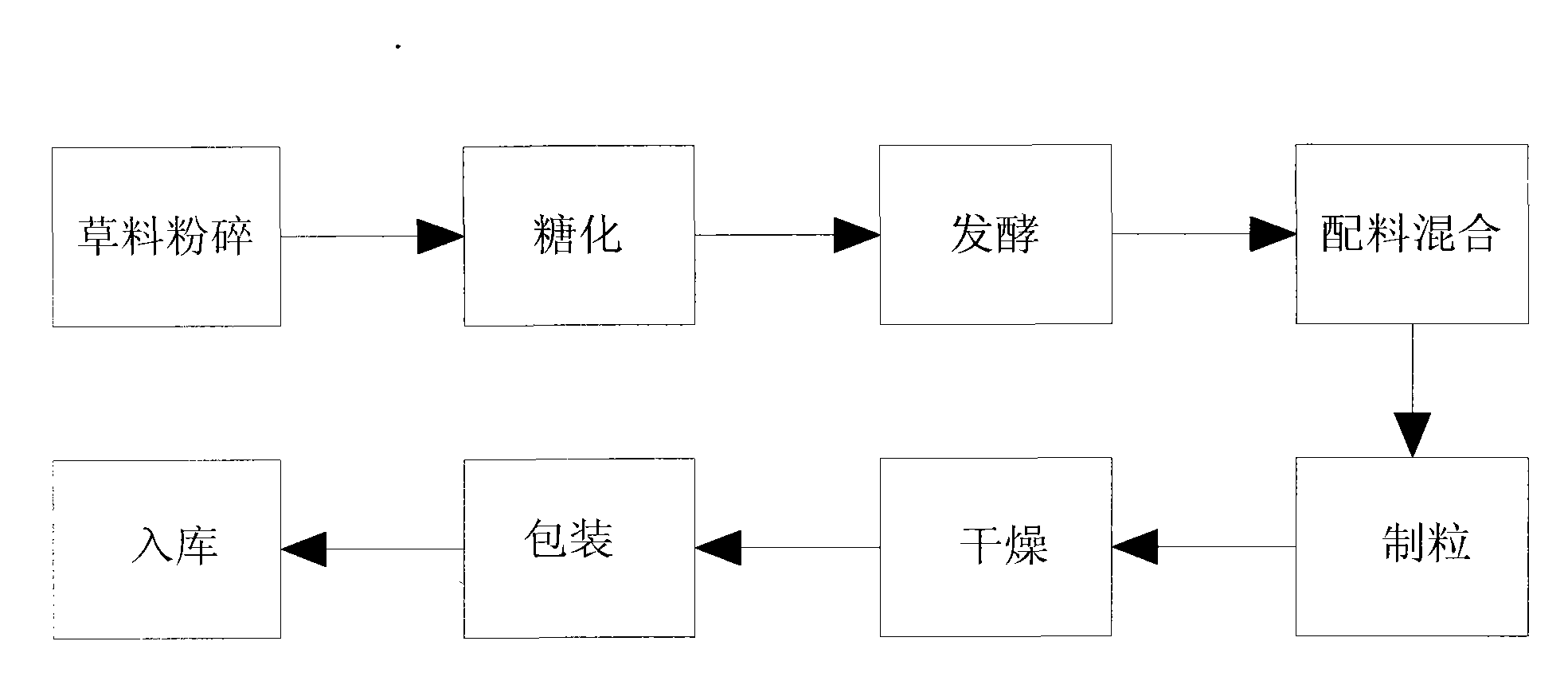

[0018] like figure 1 Shown, the present invention is a kind of production method of organic saccharified grass feed, comprises the following steps:

[0019] Step 1, crushing: the forage is crushed into granules; the forage is selected from straw or corn stalks, because the straw or corn stalks are cheap, have a large supply, and contain ingredients that are most suitable for the growth of cattle and sheep. The forage is crushed into particles with a diameter of less than 3 mm, which facilitates further processing of the forage in subsequent steps.

[0020] Step 2, saccharification: add syrup with a sugar content of 30% to the product obtained in step 1, the weight ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com