Method for purifying carabrone

A technology of Tianmingjing lactone and a purification method, which is applied in the field of purification of Tianmingjinglactone, can solve the problem of low purity of Tianmingjinglactone, and achieve the effect of simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

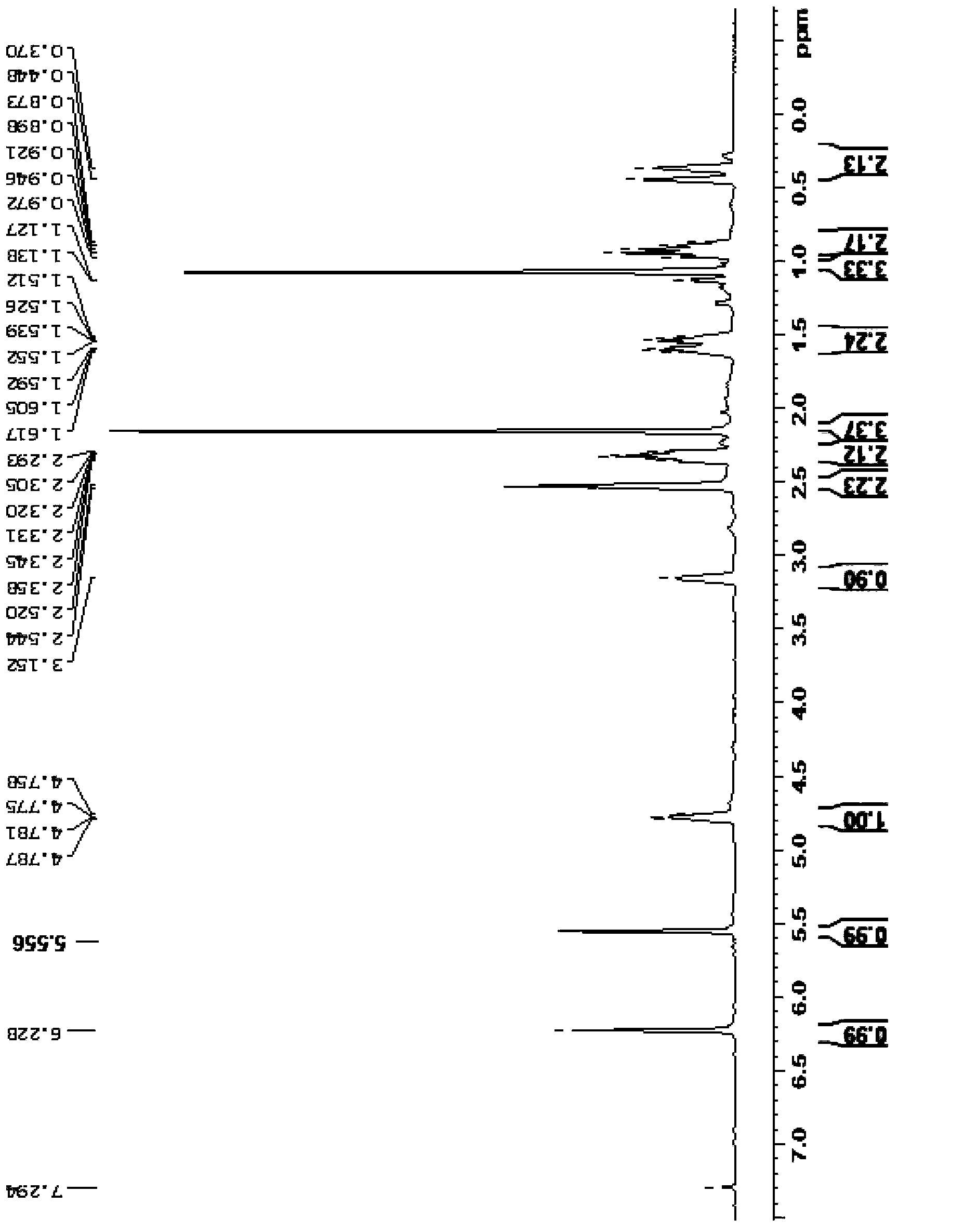

AI Technical Summary

Problems solved by technology

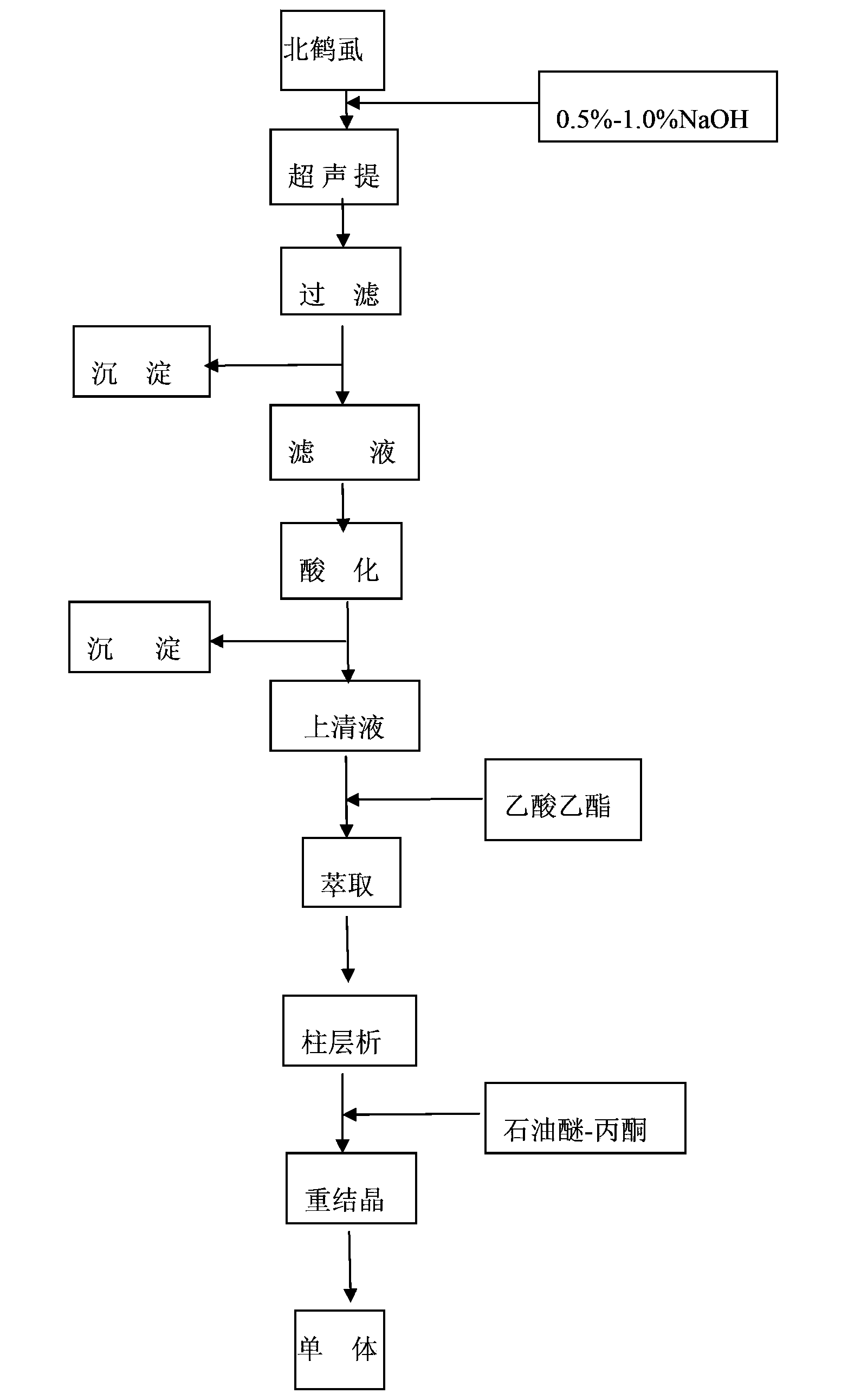

Method used

Image

Examples

Embodiment 1

[0022] The preparation process of Tianmingjing lactone ketone is a process of extracting and separating Tianmingjing lactone ketone using the northern crane locust as raw material and 0.5% NaOH solution as the extraction agent. The specific steps are as follows:

[0023] (1) Take 1kg of the northern crane lice, use 5L 0.5% (w / w) NaOH solution, ultrasonically treat at 30°C for 30 minutes, separate the northern crane lice with 200 mesh filter cloth, and then use 4L 0.5% (w / w) NaOH The solution was ultrasonically treated at 30°C for 30 minutes, and the northern crane lice was separated with a 200-mesh filter cloth; then 3L of 0.5% (w / w) NaOH solution was ultrasonically treated at 30°C for 30 minutes, and the northern crane lice was separated with a 200-mesh filter cloth ; Combine the extracts extracted three times.

[0024] (2) Add 1% (w / w) hydrochloric acid solution to the extract to neutralize at room temperature (25°C), adjust the pH to about 3, produce a precipitate, and let ...

Embodiment 2

[0031] (1) Take 5kg of northern crane lice, use 20L 1% (w / w) NaOH solution, ultrasonically treat at 30°C for 30 minutes, separate the northern crane lice with 200 mesh filter cloth, and then use 15L 1% (w / w) NaOH The solution was ultrasonically treated at 30°C for 30 minutes, and the northern crane lice was separated with a 200-mesh filter cloth; then 10L of 1% (w / w) NaOH solution was ultrasonically treated at 30°C for 30 minutes, and the northern crane lice was separated with a 200-mesh filter cloth ; Combine the extracts extracted three times.

[0032] (2) Add 3% (w / w) hydrochloric acid solution to the extract to neutralize at room temperature (25°C), adjust the pH to about 2, produce a precipitate, and let it stand.

[0033] (3) Separate the precipitated bottom from the supernatant, repeat steps (1) and (2) for the precipitated precipitate; add 2.5L ethyl acetate to the supernatant for extraction, extract three times, combine the three extracts, and concentrate.

[0034] (...

Embodiment 3

[0039] (1) Take 10kg of northern crane lice, use 25L 2% (w / w) NaOH solution, ultrasonically treat at 30°C for 30 minutes, separate the northern crane lice with 200-mesh filter cloth, and then use 20L 2% (w / w) NaOH The solution was ultrasonically treated at 30°C for 30 minutes, and the northern crane lice was separated with a 200-mesh filter cloth; then 15L of 2% (w / w) NaOH solution was ultrasonically treated at 30°C for 30 minutes, and the northern crane lice was separated with a 200-mesh filter cloth ; Combine the extracts extracted three times.

[0040] (2) Add 6% (w / w) hydrochloric acid solution to the extract filtrate of the northern crane lice, neutralize it at room temperature (25°C), adjust the pH to about 1, produce a precipitate, and let it stand.

[0041] (3) Separate the precipitated bottom from the supernatant, and repeat steps (1) and (2) for the precipitation; add 4L ethyl acetate to the supernatant for extraction, extract three times, combine the three extracts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com