Catalyst solid ingredient, catalyst containing catalyst solid ingredient and use of catalyst in olefin polymerization

A technology for polymerizing solid components and olefins, applied in the field of catalyst solid components, and can solve the problems of not finding the special advantages of DEP, not finding the application and method of DEP, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

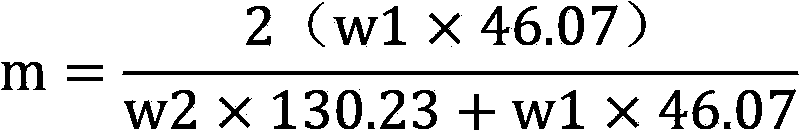

Method used

Image

Examples

Embodiment 1

[0097] Alkoxy magnesium compound (carrier) Mg(OEt) 2-m (OEHA) m Preparation of:

[0098] After the 16L pressure-resistant reactor with a stirrer was fully replaced with nitrogen, 10L of ethanol, 300mL of 2-ethylhexanol, 11.2g of iodine, 8g of magnesium chloride and 640g of magnesium powder were added to the reactor. While stirring, the temperature of the system was raised to 75° C. for reflux reaction until no more hydrogen gas was discharged. Stop the reaction, wash with 3L ethanol, filter and dry. The obtained alkoxymagnesium support. The D50 of the obtained alkoxymagnesium carrier was 30.2 μm, the span value was 0.81, and the m value was 0.015.

[0099] The preparation of catalyst solid component A1:

[0100] Take 650g of the above alkoxymagnesium compound, 3250mL of toluene and 65mL of diethyl phthalate (DEP) to prepare a suspension. In a 16L pressure-resistant reactor that has been repeatedly replaced by high-purity nitrogen, add 2600 mL of toluene and 3900 mL of ti...

Embodiment 2

[0112] Polymerization reaction of olefins at high temperature (95°C):

[0113]The 3.5 liter autoclave connected to the catalyst feeder, propylene and hydrogen feed lines was fully replaced with gaseous propylene. Add 5 mL of a hexane solution of triethylaluminum (the concentration of triethylaluminum is 0.5 mol / L) and 1 mL of a hexane solution of dicyclopentyldimethoxysilane (DCPMS) into the catalyst feeder at room temperature ( The concentration of DCPMS is 0.1 mol / L), 10 mL of anhydrous hexane and 10-14 mg of the catalyst solid component A1 prepared in Example 1, mixed for 2 minutes (pre-complexation), and then added to the autoclave. Close the autoclave, introduce 1.35 standard liters of hydrogen and 2.4 L of liquid propylene; stir at room temperature for 5 minutes (equivalent to prepolymerization); and raise the temperature to 95°C within 20 minutes under stirring. After the polymerization reaction at 95° C. for 1 hour, the stirring was stopped, the unpolymerized propylen...

Embodiment 3

[0115] High temperature (110°C) polymerization of olefins:

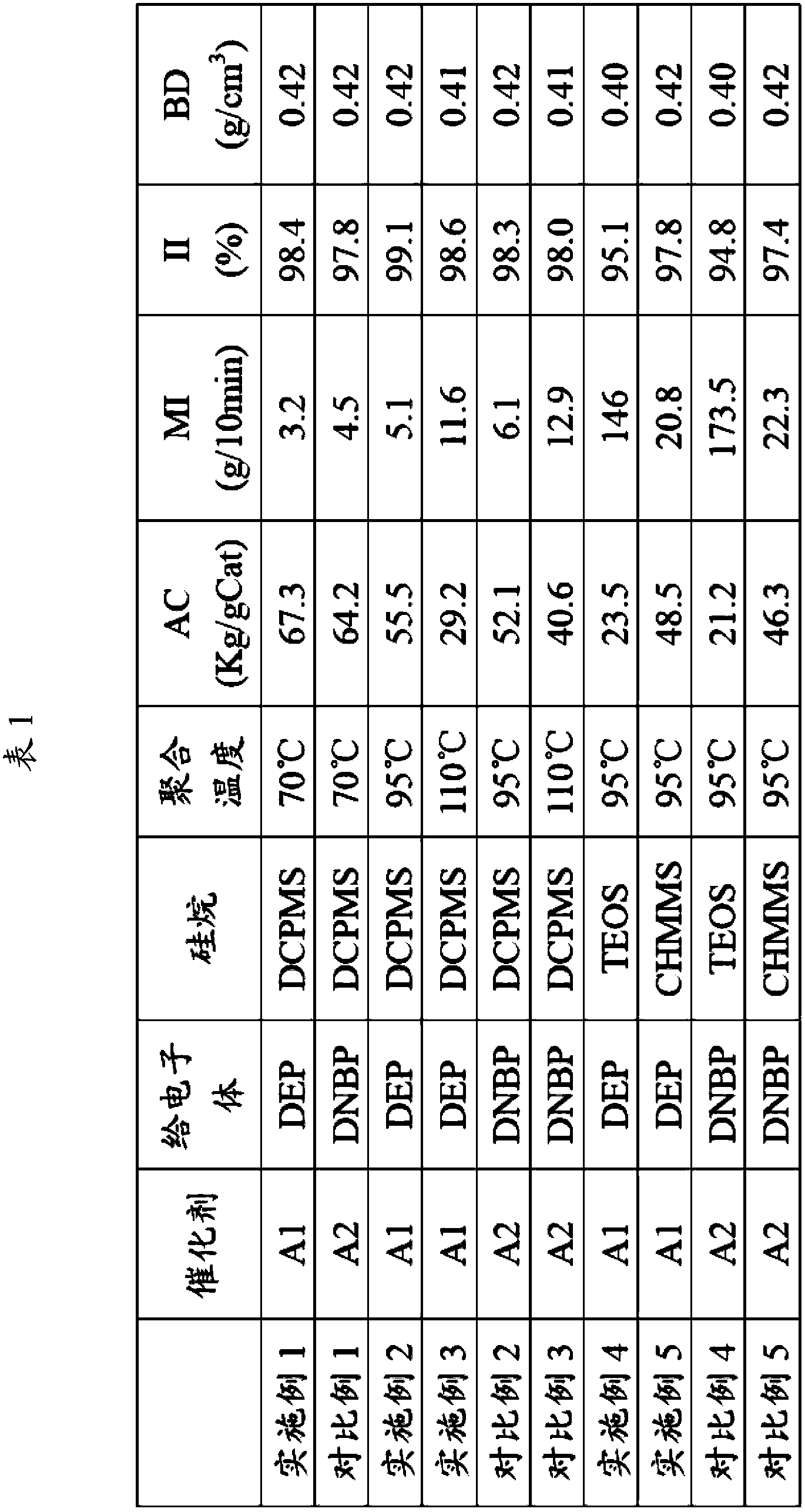

[0116] Using the catalyst solid component A1 prepared in Example 1, the polymerization was carried out according to the polymerization method of Example 2, except that the polymerization temperature was changed from 95°C to 110°C. The results of polymerization activity, polymer melt index (MI), polymer isotacticity (II) and polymer bulk density (BD) are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com