Propylene copolymer and preparation method thereof

A propylene copolymer and propylene technology, which is applied in the field of propylene copolymer and its preparation, can solve the problems of not being able to take into account polymerization activity, hydrogen adjustment sensitivity, melt flow index rigidity and impact resistance at the same time, and achieve rigidity and impact resistance. Performance enhancement, effect of high melt flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention provides a kind of preparation method of propylene copolymer, and this method comprises the following steps:

[0017] (1) In the presence of a Ziegler-Natta catalyst, prepolymerize propylene at -10°C to 50°C and 0.1-10MPa for 4-20 minutes to obtain a propylene prepolymer;

[0018] (2) In the presence of the propylene prepolymer obtained in step (1), conduct gas-phase polymerization of propylene at 91-130°C and 1-5 MPa for 40-120 minutes to obtain a propylene homopolymer;

[0019] (3) In the presence of the propylene homopolymer obtained in step (2), gas-phase polymerize propylene and α-olefin at 50-150°C and 1-5MPa for 20-120 minutes to obtain a propylene copolymer, wherein the α-Olefin is the number of carbon atoms is C 2 -C 6 but not for C 3 at least one of .

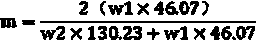

[0020] In the present invention, "prepolymerization ratio" refers to the ratio of the weight of the prepolymer to the weight of the original catalyst added. Usually for batch prepolym...

preparation example 1

[0082] This preparation example is used to prepare the catalyst solid component used in the preparation method of the propylene copolymer of the present invention.

[0083] After fully replacing the 16L pressure-resistant reactor with agitator with nitrogen, add 10L ethanol, 300mL 2-ethylhexanol, 11.2g iodine, 8g magnesium chloride and 640g magnesium powder into the reactor. While stirring, the system was refluxed until no more hydrogen was released. Stop the reaction, wash with 3L ethanol, filter and dry. The resulting dialkoxymagnesium support. The resulting dialkoxymagnesium carrier has a D50 of 30.2 μm, a span value of 0.81, and an m value of 0.015.

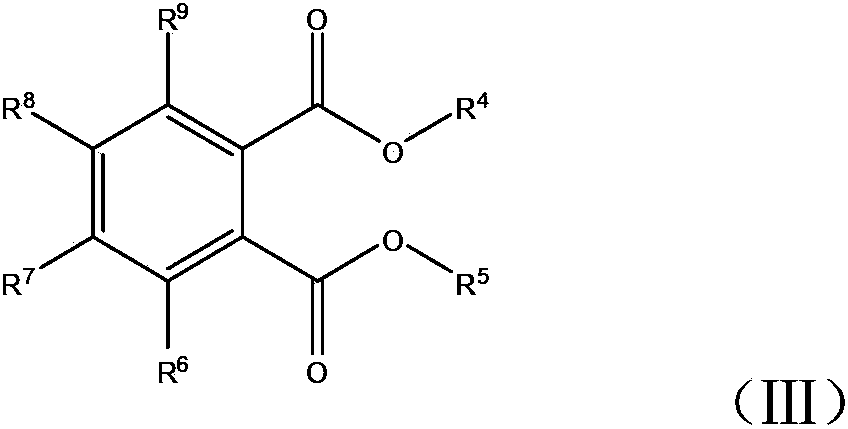

[0084] Take 650g of the above alkoxymagnesium compound, 3250mL of toluene and 65mL of diethyl phthalate (DEP) to prepare a suspension. In a 16L pressure-resistant reactor that has been repeatedly replaced by high-purity nitrogen, add 2600 mL of toluene and 3900 mL of titanium tetrachloride, raise the temperature to 80 ° C,...

Embodiment 1

[0086] This example is used to illustrate the propylene copolymer provided by the present invention and its preparation method.

[0087] The experiment adopts continuous tank type prepolymerization and horizontal tank gas phase series polymerization process. The volume of the pre-polymerization reactor is 5 liters, it is a vertical stirring tank with jacket cooling, the stirring blade is a turbine-type oblique paddle, and the stirring speed is 500 rpm; the volume of the horizontal gas phase reactor is 0.2 cubic meters, it is a horizontal Stirring, the stirring blade is a T-shaped inclined blade, the inclination angle is 10 degrees, and the stirring speed is 100 rpm, wherein the gas phase homopolymerization of propylene in step (2) and the copolymerization of gas phase propylene and ethylene in step (3) are homogeneous Carried out in a horizontal gas phase reactor.

[0088] Step (1) pre-polymerization: the reaction pressure is 2.5MPa, the reaction temperature is 10°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com