Catalyst component for olefin polymerization, preparation method of catalyst component, catalyst, application of catalyst, polyolefin and preparation method of polyolefin

A technology of olefin polymerization and catalyst, which is applied in the field of catalyst and its application and polyolefin and its preparation, which can solve the problems of high polymer fine powder content, poor hydrogenation sensitivity, poor catalyst morphology, etc., and achieve melt flow index High, wide molecular weight distribution, good morphology of olefin polymerization catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

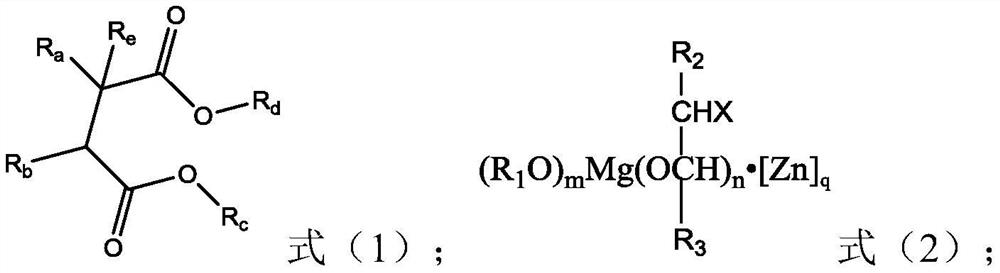

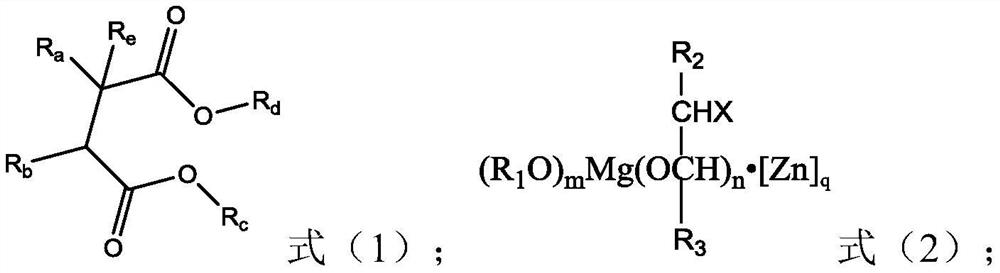

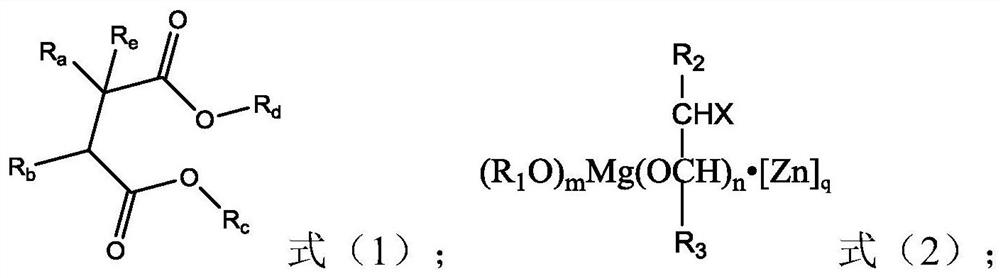

[0091] In a second aspect of the present invention, according to a preferred embodiment of the present invention, the method includes:

[0092] Mix the titanium-containing compound and the carrier at minus 30°C to minus 120°C, then add the internal electron donor compound into the mixed system, and raise the temperature to 80°C to 130°C to carry out the contact reaction, The catalyst component is obtained.

[0093] According to the first and second aspects of the present invention, preferably, the carrier represented by formula (2) is prepared by the following method:

[0094] (1) Under the condition that an inert liquid medium is optionally present, the components in the first component are mixed and emulsified in turn to obtain an emulsified product. The first component contains zinc metal elemental, represented by the formula MgXY Magnesium halide and formula R 1 Alcohol compounds represented by OH;

[0095] (2) reacting the emulsified product with the second component, ...

preparation example 1

[0163] It is used to illustrate the preparation of the catalyst support of the present invention.

[0164] (1) In a 0.6L reaction kettle, add 0.08mol magnesium chloride, 0.96mol ethanol, 0.015mol zinc powder (average particle size 15 microns), 0.3g polyvinylpyrrolidone, and heat up to 90°C under stirring. After constant temperature reaction for 2 hours, then emulsification to obtain emulsified product;

[0165] (2) Add 0.48mol epichlorohydrin to the emulsified product to carry out contact reaction. The conditions of contact reaction include: the temperature is 90° C., the time is 30 min, press filter after the reaction, and wash the press filter product 5 times with hexane , and vacuum-dried to obtain a catalyst spherical carrier Z1 for olefin polymerization.

[0166] After testing, the composition of the catalyst carrier Z1 is:

[0167]

[0168] After testing, the average particle diameter (D50) of the catalyst carrier Z1 is 59 microns, and the particle size distribution...

preparation example 2

[0171] It is used to illustrate the preparation of the catalyst support of the present invention.

[0172] (1) In a 0.6L reaction kettle, add 300mL white oil, 0.08mol magnesium chloride, 0.48mol ethanol, 0.015mol zinc powder (average particle size 11 microns), 0.3g polyvinylpyrrolidone, and heat up to 100°C under stirring, After constant temperature reaction for 1 hour, emulsification is then obtained to obtain an emulsified product;

[0173] (2) Add 0.16mol epichlorohydrin to the emulsified product to carry out contact reaction, the conditions of contact reaction include: the temperature is 100°C, the time is 20min, press filter after the reaction, and wash the press filter product 5 times with hexane , and finally the product was vacuum-dried to obtain a spherical carrier Z2 for an olefin polymerization catalyst.

[0174] After testing, the composition of the carrier Z2 is:

[0175]

[0176] After testing, the average particle diameter (D50) of the carrier Z2 is 51 micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com