A kind of high-viscosity easy-processing ethylene terephthalate and preparation method thereof

A technology of polyethylene terephthalate and ethylene terephthalate, which is applied in the field of ethylene terephthalate resin, can solve problems such as material processing performance not being improved, and achieve a change in molecular weight distribution. , The effect of improving crystallinity and wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

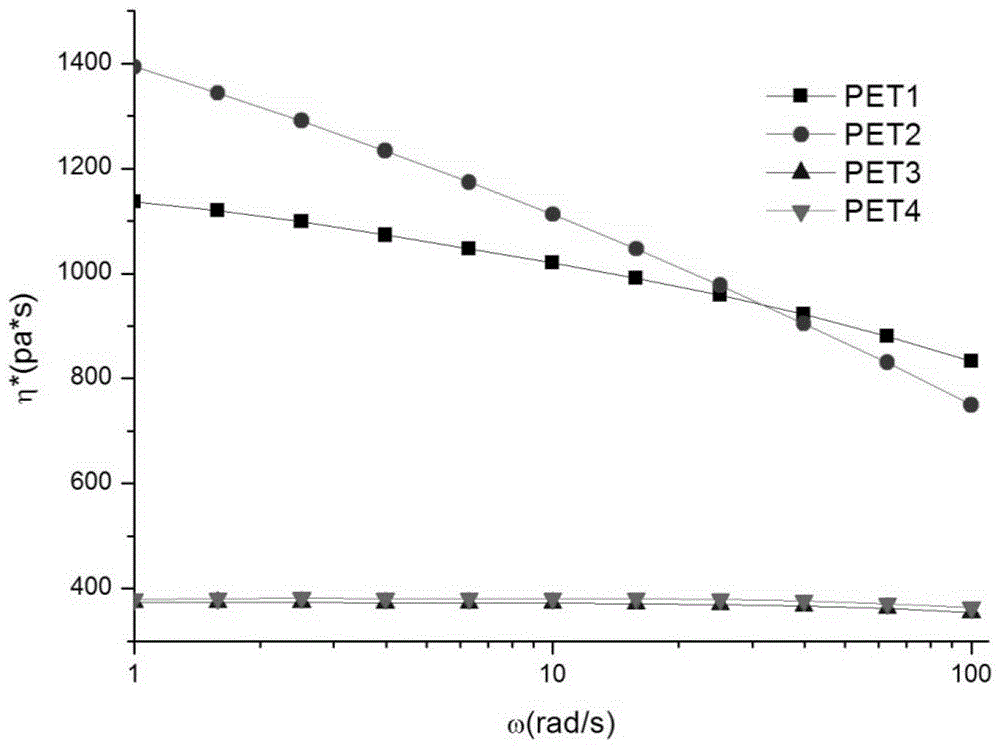

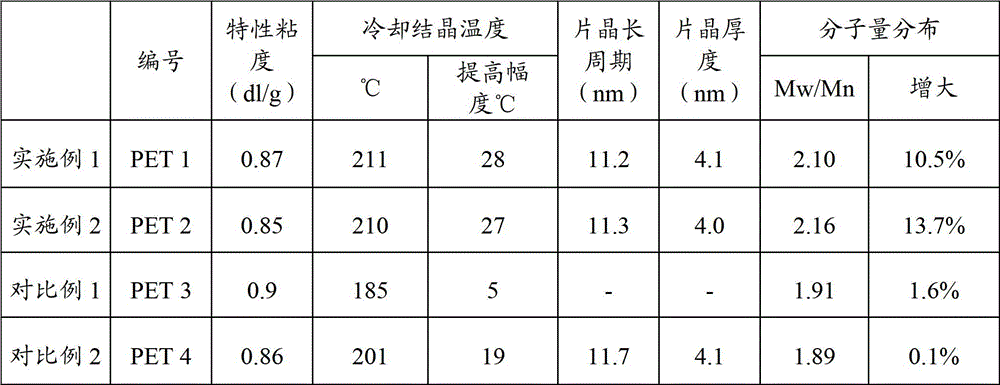

[0031] Take 500g of PET slices with an intrinsic viscosity of 0.98dl / g, produced by Yizheng Chemical Fiber, and dry them in a common oven at 110°C for 24 hours, and then dry them in a vacuum oven at 100°C for 12 hours. Take 0.5 g of glycerol (produced by Beijing Chemical Reagent Factory) and 1 g of nucleating agent, add the weighed mixture into a high-speed mixer, and mix for 4 minutes to form a uniform mixture. Then it is fed into a twin-screw extruder by a feeder, blended and extruded into strips, and then pelletized by a pelletizer.

[0032] The processing technology is: the temperature of the first zone of the twin-screw extruder is 230°C, the temperature of the second zone is 270°C, the temperature of the third zone is 275°C, the temperature of the fourth zone is 280°C, and the die temperature is 285°C.

[0033] See Table 1 for the data.

Embodiment 2

[0035] With embodiment 1, difference is to adopt pentaerythritol as branching agent, and its consumption is 0.3g. See Table 1 for the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com