Hydraulic engineering vertical water stop structure and manufacturing and construction method thereof

A vertical water stop and water conservancy engineering technology, applied in water conservancy projects, underwater structures, sea area engineering, etc., can solve problems such as difficult cleaning, prolonging the construction period, and inability to pour continuously, so as to save installation procedures, reduce construction period, The effect of preventing cross-sectional interface misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

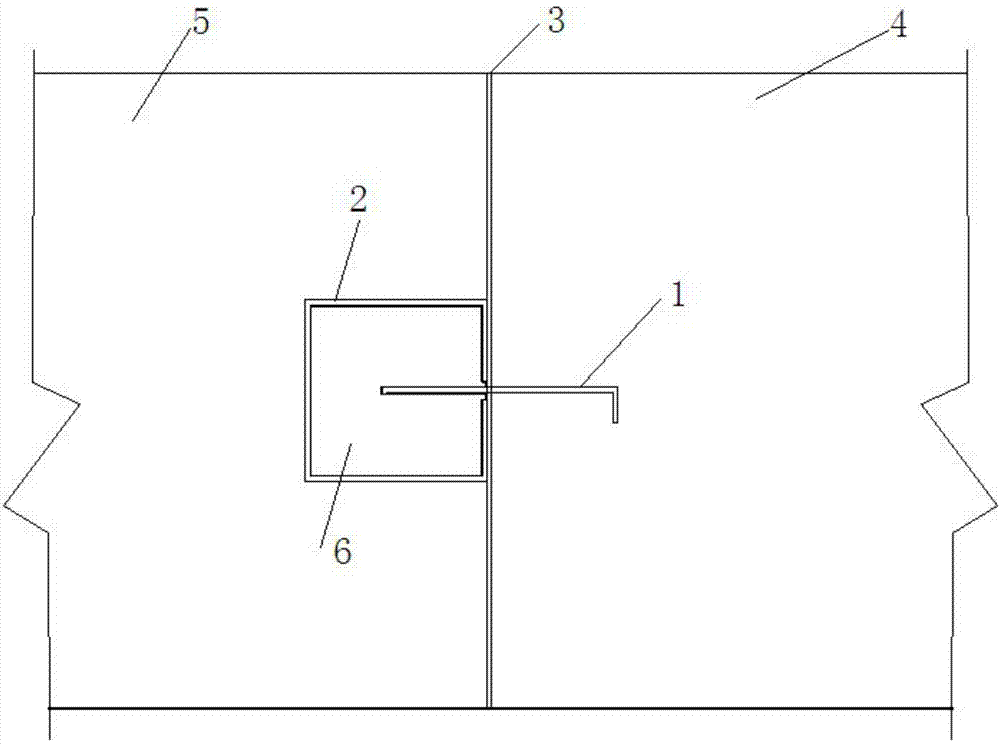

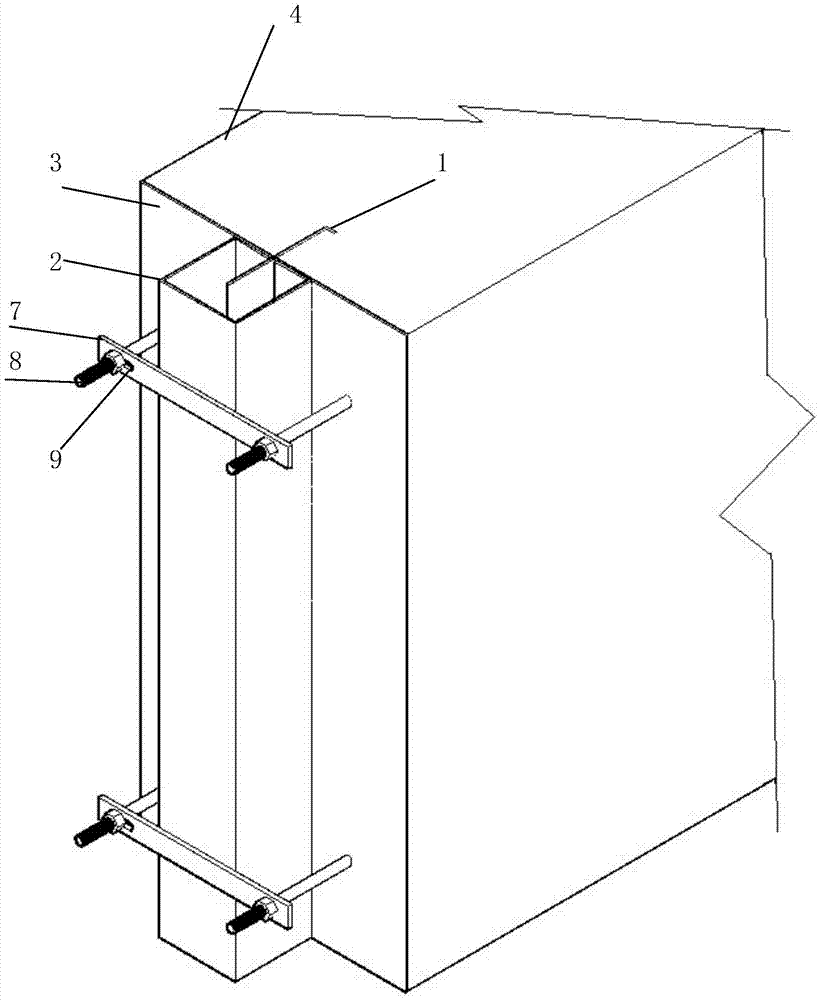

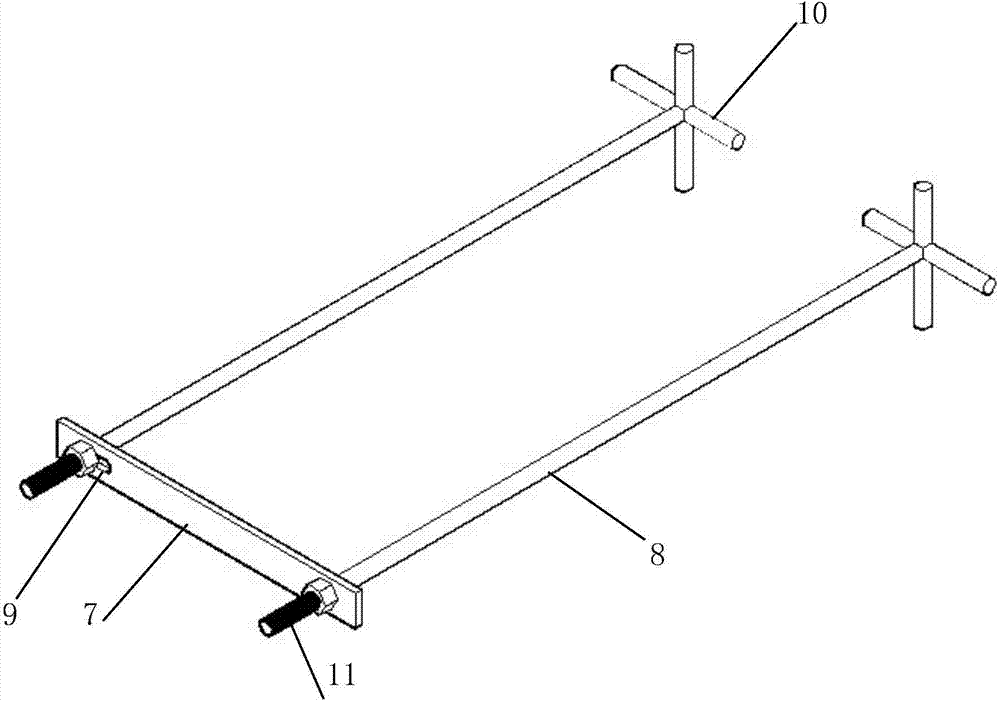

[0040] Embodiment, referring to the accompanying drawings: a vertical water stop structure for water conservancy projects, including a copper sheet 1, a channel steel 2 and a fixing device, one side of the copper sheet 1 is prefabricated in the first-stage concrete 4, and the other side is Protruding from the concrete section, it is placed in the channel steel opening 12, the copper sheet 1 extends into the channel steel 2 to a certain depth, and the channel steel 2 is provided with soft asphalt 6; the channel steel opening 12 surface and the first-stage concrete 4 section Asphalt felt 3 is arranged on both sides of the copper sheet 1, and one end of the fixing device is pre-embedded in the first-stage concrete 4, and the other end is arranged on both sides of the channel steel 2, and the channel steel 2 is fixed on the channel steel 2 by flat iron 7 and nuts Phase I concrete 4 sections.

[0041] Further, the thickness of the copper sheet 1 is 1-3mm, the width is 40-80cm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com