Simulation detection system for explosion of underground storage gasoline tank in automobile gasoline filling station

A detection system and gas station technology, applied in the field of explosion simulation systems, can solve problems such as accidents, fires, and electrostatic ignition of oil and gas without gas stations buried in oil tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be explained in detail with reference to the drawings.

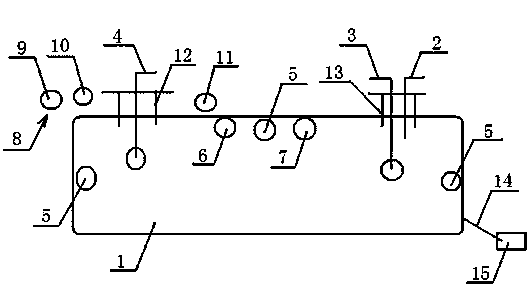

[0022] Such as figure 1 The combustion and explosion simulation detection system of the buried oil tank of a gas station according to the embodiment of the present invention shown in FIG. includes a simulation device and a detection device.

[0023] The simulation device includes a buried oil tank 1, an oil injection pipeline for inputting oil and gas 2, a level gauge 3 and an igniter 4. The oil injection pipeline 2 communicates with the buried oil tank 1 and is used to input the simulated oil and gas into the buried oil tank 1. The level gauge 3 and the igniter 4 are arranged in the buried oil tank. The level gauge 3 is used to simulate the oil level in the buried oil tank 1 before the accident, and the igniter 4 is used for ignition.

[0024] The detection device includes a concentration monitor 5 for monitoring the concentration of oil and gas, a first pressure sensor 6 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com