High-voltage divider

A high-voltage voltage divider, voltage divider technology, applied in the direction of voltage divider, can solve the problems of distribution parameter influence, complex technical parameters, etc., to achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

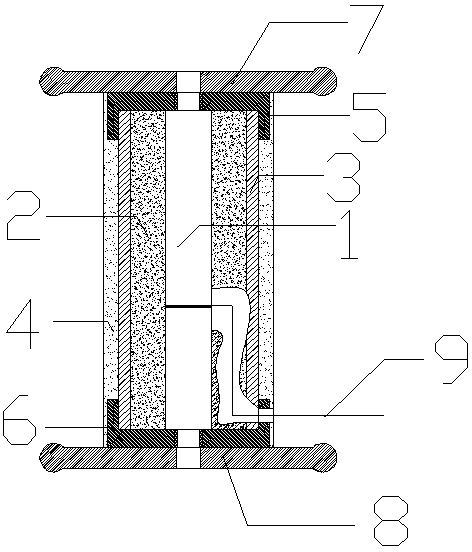

[0014] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the core of the present invention is a ceramic rod coated with a resistance film of the high and low voltage arms, which is used as the body 1 of the voltage divider, and the signal electrode 9 is drawn out from the body 1 of the voltage divider. Insulation medium 2, resistance 3 for equipotential shielding and a layer of buffer film 4 coated on the outside of equipotential shielding resistance 3, silver-plated copper caps with threaded holes are installed at both ends of the voltage divider to lead out high-voltage electrodes 5 and ground electrodes 6. A high voltage equalizing shield 7 and a grounding equalizing shield 8 are installed on the high voltage electrode 5 and the ground electrode 6 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com