Preparation method of soft beancurd

A technology of water tofu and tofu skin, which is applied in the deep processing of water tofu products and in the field of water tofu meals and dishes. It can solve the problems of poor strength, increase the strength of water tofu, and large water consumption, so as to reduce production costs, save seasonings, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

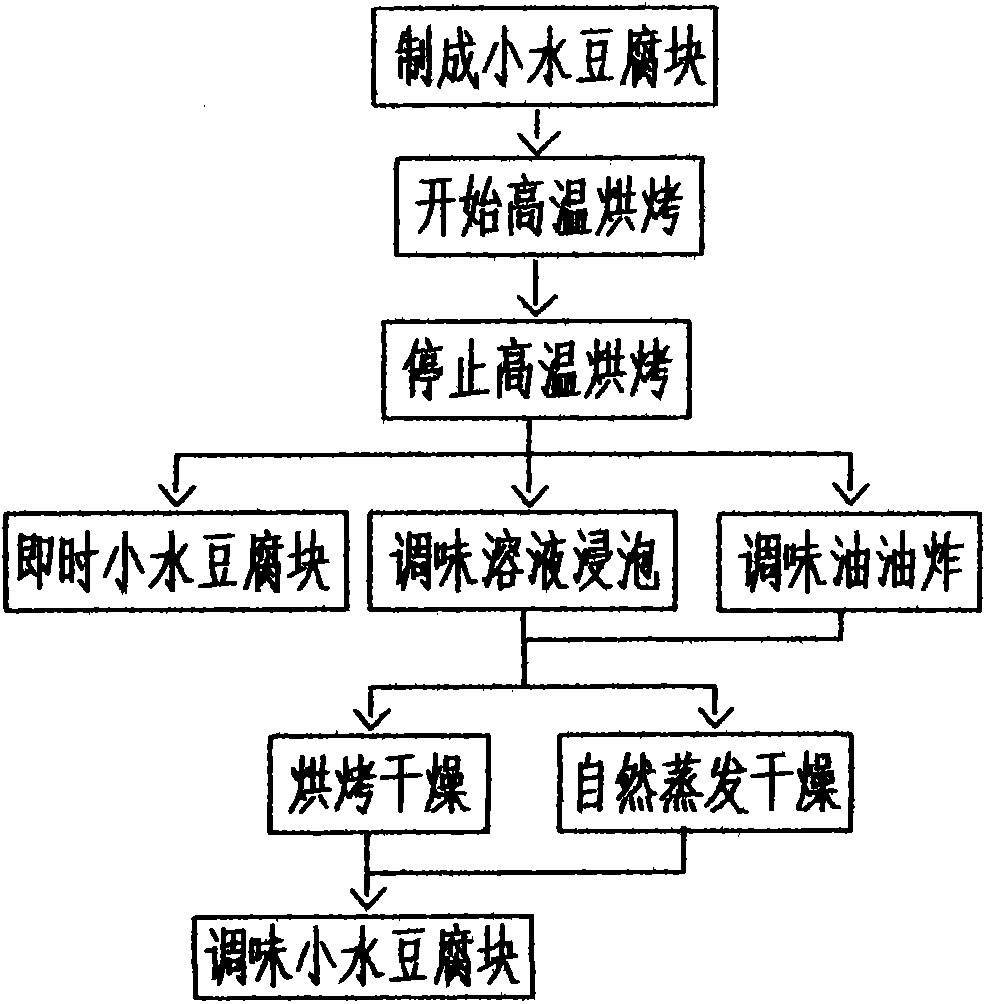

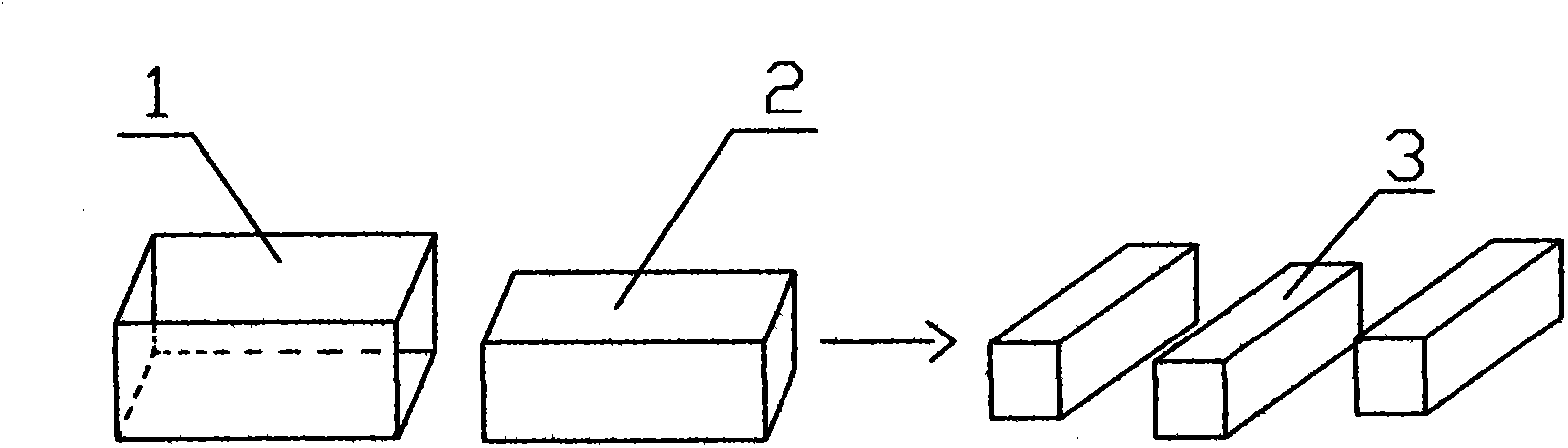

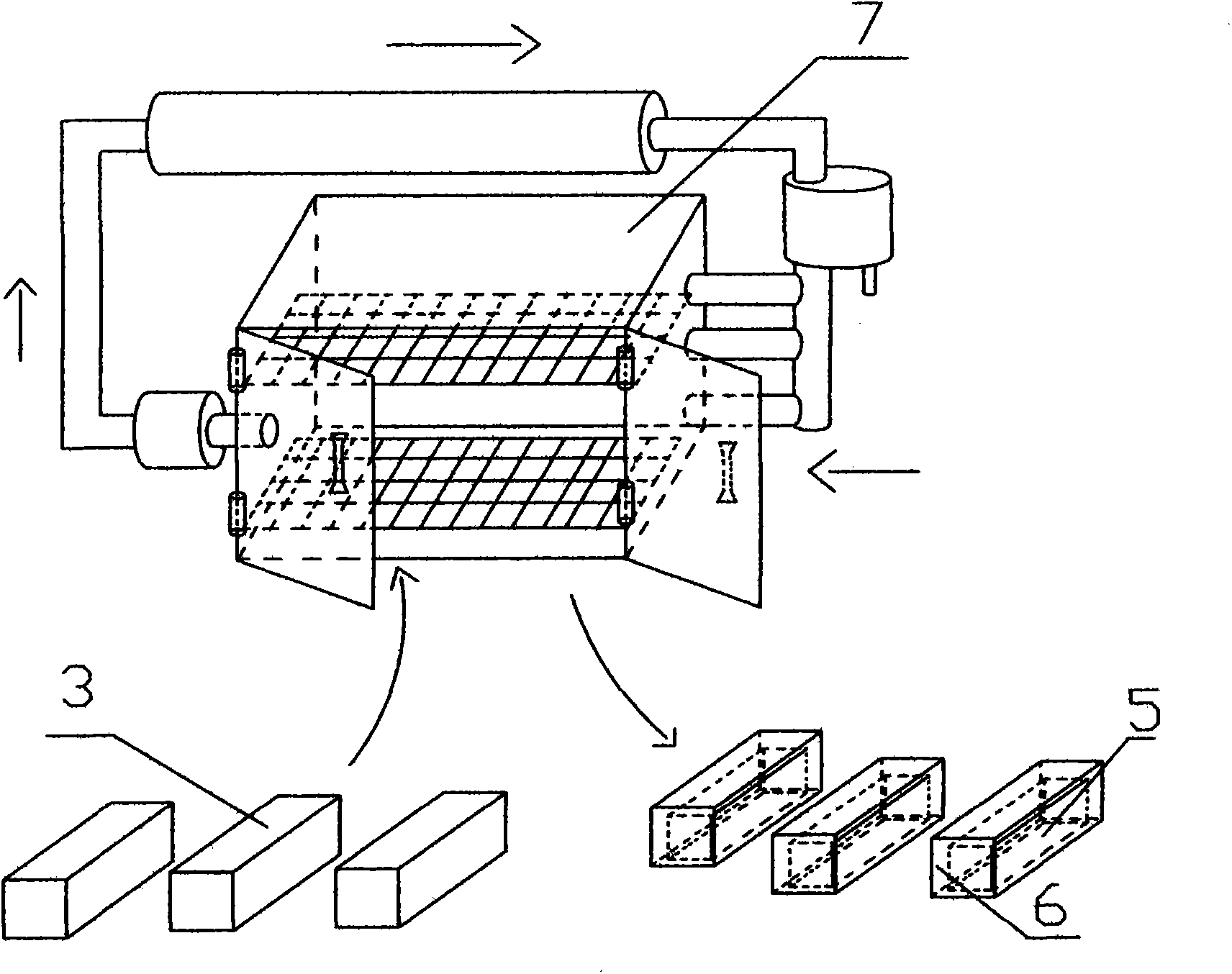

[0036] The preparation method includes the following steps: step 1, making the large-volume water tofu 2 into small water tofu pieces 3 with the large-volume water tofu 2 as a reference, the operation process of the step 1: 1. The volumetric water tofu 2 is cut into small water tofu pieces 3 with the large-volume water tofu 2 as a reference. The process conditions of this step 1: the moisture content range of the large-volume water tofu 2: 80% to 90%, The water content range of the small tofu cubes 3: 80% to 90%, step 2, start baking, the operation process of this step 2: 1. Send the small water tofu cubes 3 into the baking equipment 7, this step Process conditions of 2: baking Heat transfer medium: gas, step 3, stop baking, the operation process of this step 3: 1. Remove the water tofu block composed of tofu skin 6 and internal water tofu 5 from the baking equipment 7 Send out, the process conditions of step 3: the thickness of the tofu skin 6 reaches the thickness range: 0.5...

Embodiment 1

[0047] Instant water tofu block making

[0048] From figure 2 and image 3 It can be seen that, for the water tofu 2 pressed by the mold 1, if the weight of the water tofu 2 is 18 kg, the steps of this embodiment are as follows: Step 1, making the large-volume water tofu 2 into the large-volume water tofu 2 The small water tofu block 3 as a reference object, the operation process of the step 1: 1. Cut the large-volume 18-jin water tofu 2 into 36 pieces with a weight of 250 grams using the large-volume 18-jin water tofu 2 as a reference object / block, small water tofu block 3 with a thickness of 10 mm / block, the test result of the step 1: the water content of the large-volume 18 kg water tofu 2 is 82.5%, the weight is 250 grams / block, and the thickness is 10 mm / block The water content of small tofu cubes 3 is 82.3%, step 2, start baking, the operation process of step 2: 1. Send 36 small tofu cubes 3 with a weight of 250 g / block and a thickness of 10 mm / block into In the ba...

Embodiment 2

[0050] Making hot pot base flavored tofu cubes

[0051] From figure 2 , image 3 , Figure 4 It can be seen that the water tofu 2 pressed by the mold 1, if the weight of the water tofu 2: 30 catties, the seasoning solution soaking container 8 is filled with hot pot seasoning seasoning solution: the finished hot pot base produced by the hot pot base manufacturer, specification: 1 kg / bag, select 6 bags of chafing dish bottom material to blend with 28 jin of drinking water, and boil it into a boiling seasoning solution at 90°C. The steps of this embodiment are as follows: step 1, make the large-volume water tofu 2 into a small water tofu block 3 with the large-volume water tofu 2 as a reference, the operation process of this step 1: 1. The volume of 30 jin of tofu 2 is cut into 187 pieces of small tofu blocks 3 with a weight of 80 grams / block and a thickness of 8 mm / block with the large volume of 30 jin of tofu 2 as a reference. The test results of this step 1: The moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com