Two-stage-tandem PSA (pressure swing adsorption) oxygen production system capable of increasing recovery rate of oxygen and operating method of two-stage PSA oxygen production system

A pressure swing adsorption oxygen production and pressure swing adsorption technology, which is applied in the direction of oxygen preparation, separation methods, chemical instruments and methods, etc., can solve the problems of high cost, oxygen recovery rate limited to less than 50%, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

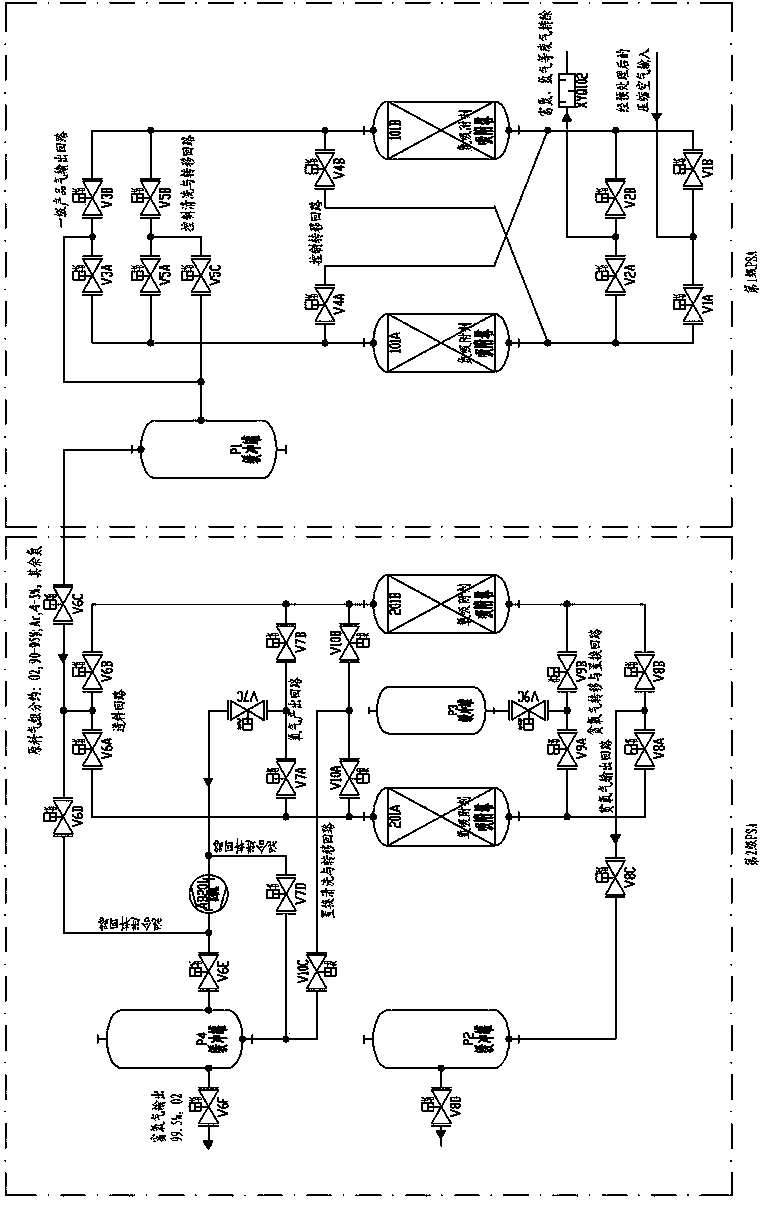

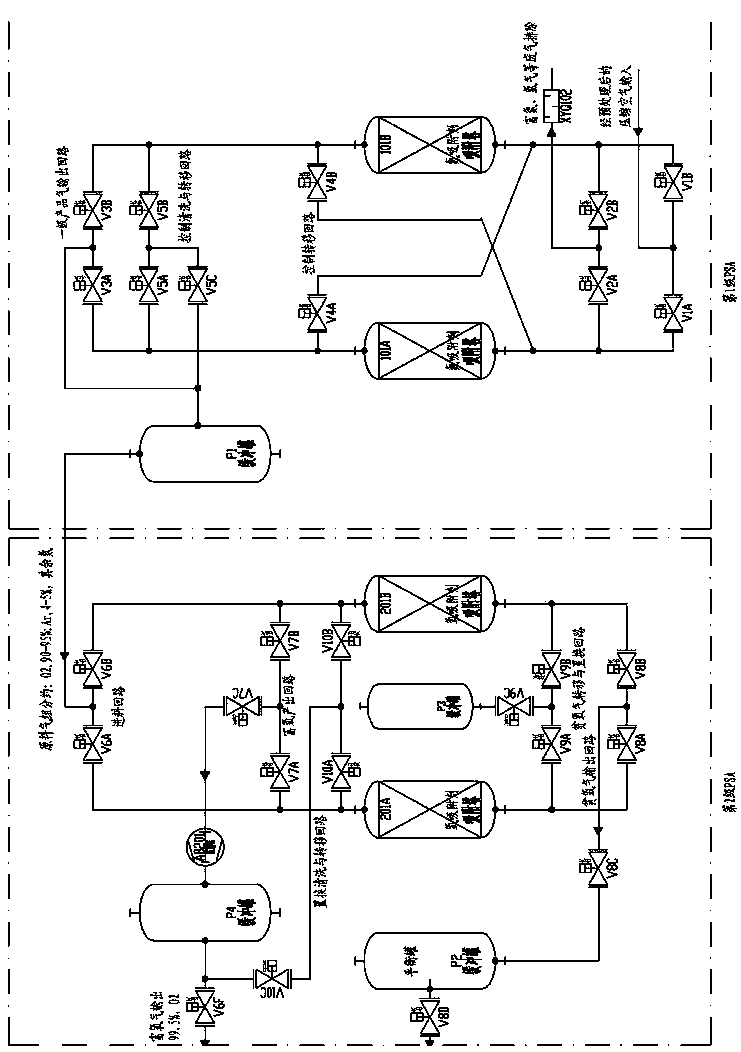

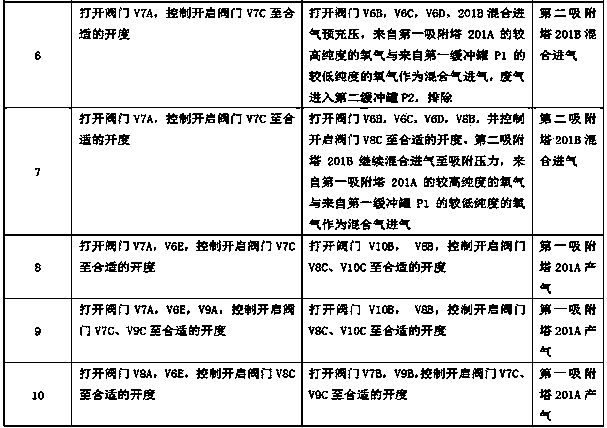

[0055] figure 1 The second-stage PSA is a two-bed pressure swing adsorption oxygen-argon separation method and device based on an equilibrium adsorption mechanism equipped with an oxygen-selective adsorbent. The second-level PSA is mainly composed of the following components:

[0056] (1) Two adsorption towers 201A and 201B, each of which is filled with 75kg of oxygen-selective adsorbent produced by Shanghai Stuff Material Technology Co., Ltd., which can absorb oxygen from mixed gas containing oxygen and argon;

[0057] (2) A second buffer tank P2, with a volume of 100L, filled with adsorbents that enhance the buffering effect;

[0058] (3) One third buffer tank P3, with a volume of 100L, filled with adsorbents to enhance the buffer effect;

[0059] (4) One fourth buffer tank P4, with a volume of 200L, filled with adsorbents to enhance the buffer effect;

[0060] (5) 1 oxygen compressor with installed power of 5.5KW, boosting capacity of 0.4MPa (gauge pressure), and volumet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com