Laser compound treatment method and device of perforated plate bushings

A perforated plate bushing and composite processing technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of limited thickness of carburized layer, large number of bushings, large bushing wall thickness, etc. Simple, improved abrasion resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

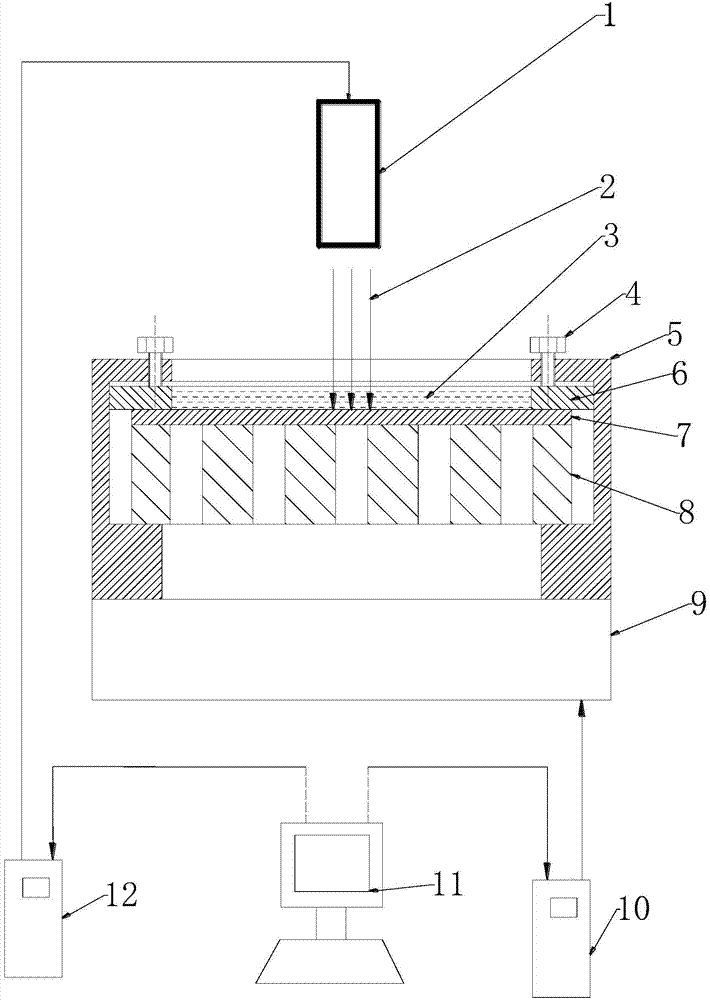

[0033] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

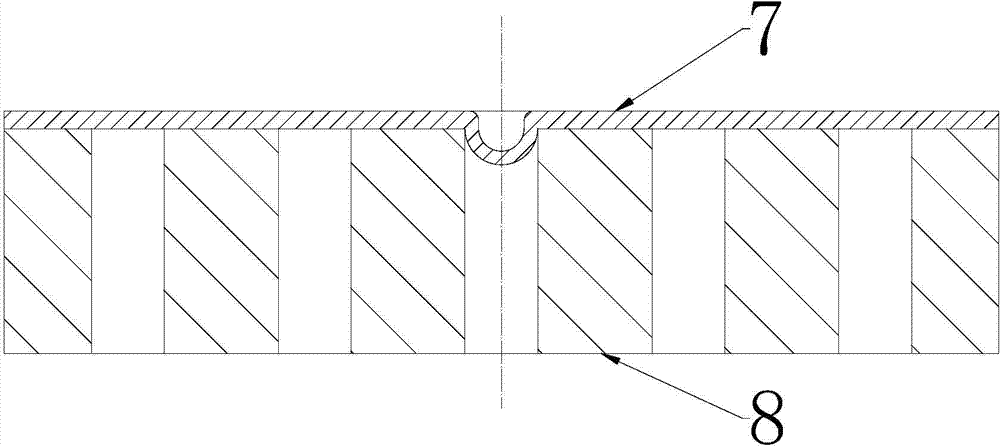

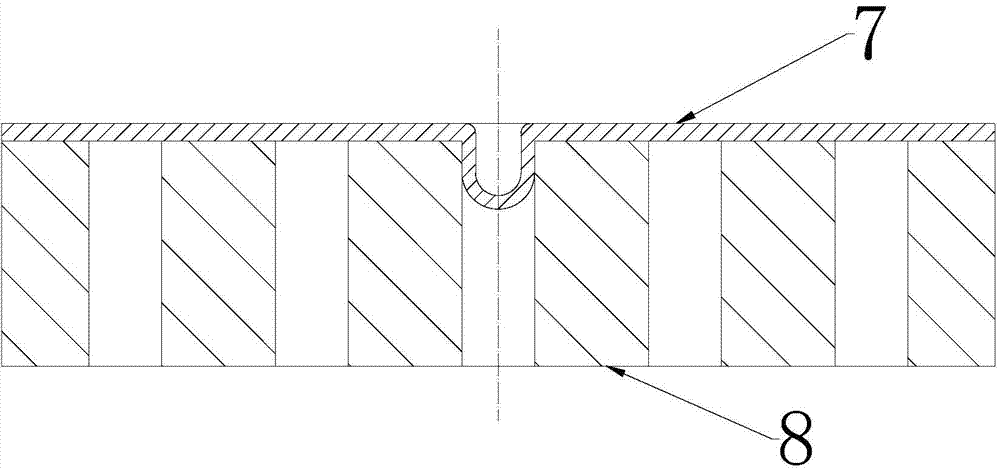

[0034] The device for implementing the present invention is a laser shock composite processing device for a porous plate liner, including a laser generator 1, a transparent liquid 2, a blank holder 6, a clamp 5, a composite layer 7, a porous plate 8, a workbench 9, and a workbench Control device 10, computer 11, laser generator control device 12, an inverted "C"-shaped fixture 5 is provided on the workbench 9, and a perforated plate 8, a composite layer 7, and a blank holder are arranged in the "C"-shaped mouth of the fixture 5. ring 6, a composite layer 7 is placed on the porous plate 8, an annular blank holder 6 is arranged above the composite layer 7, and the composite layer 7 and the porous plate 8 are pressed by the compression screw 4 on the clamp 5, above the composite layer 7, A transparent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com