Stacked spiral sludge dewatering machine

A sludge dewatering machine and stacking screw technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of sludge leakage, material cost of moving filter, and influence on treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

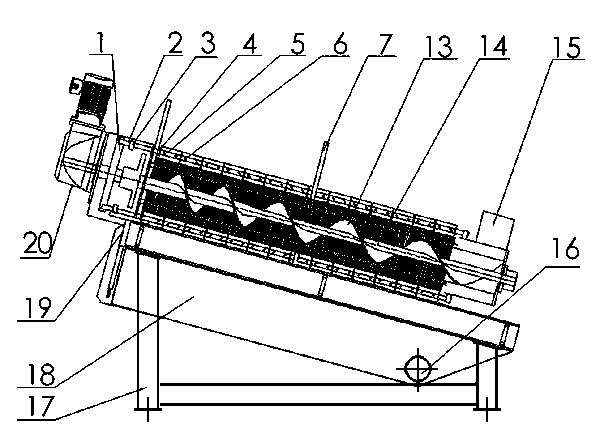

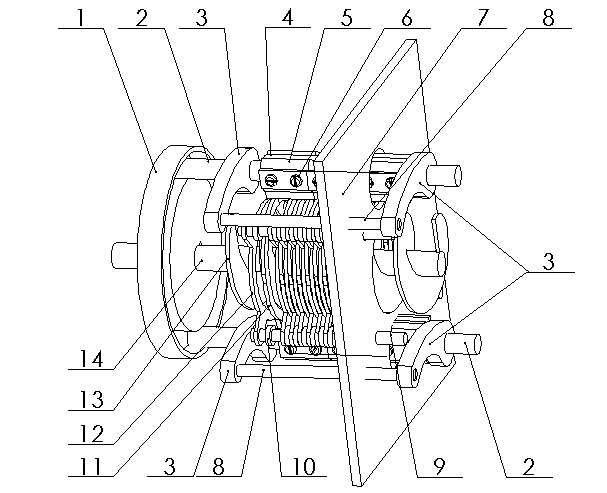

[0014] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only reversely show the constructions related to the present invention.

[0015] like Figure 1 to Figure 6 As shown, the stacked screw sludge dewatering machine includes an organic base 17, a water collection tank 18, a mud outlet 19, a reducer 20, a water inlet 15, a water outlet 16, an eccentric disk 1, an eccentric disk chute 101, and a swing shaft 2. Rocker arm 3, swing sleeve 4, fixed clip 5, fixed clip screw 6, support plate 7, rocker arm support shaft 8, fixed filter positioning shaft 9, fixed filter spacer 10, moving filter 11, fixed filter Filter disc 12, helical disc 13, helical shaft 14.

[0016] The base 17 is equipped with a plurality of support plates 7 arranged in paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com