Foam rubber material for weather strip

A foam rubber, weather stripping technology, applied in the directions of adhesives, transportation and packaging, films/sheets without carriers, etc., can solve the problems of poor compression set, large compression set value, inability to have satisfactory watertight performance, etc. High water tightness, less restrictive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0081] The blending ingredients (parts by mass) shown in Table 1 were kneaded to obtain a rubber composition, which was extruded into a sheet, vulcanized and foamed in a high-temperature atmosphere to produce a crosslinked rubber sponge material (foam rubber Material).

[0082] Table 1

[0083]

Example 1

Comparative example 1

(a) Olefin rubber

100

100

(b) Terpene resin

50

-

(d) carbon black

60

60

(e) Inorganic filler

10

10

(f) softener

90

90

(c) Blowing agent

15

15

(g) Cross-linking agent

1

1

(h) Vulcanization accelerator

8

8

Total (parts by mass)

334

284

[0084] In Table 1, component (a) is ethylene-α-olefin-based copolymer rubber, specifically EPDM, and component (b) is terpene resin (YS Resin TO-105 (manufactured by Yasuhara Chemical Co., Ltd.) , component (c) is ADCA (azodicarbonamide) and OBSH (oxybisbenzenesulf...

Embodiment 2 and comparative example 2

[0108] Each of the crosslinked rubber sponge materials of Example 1 and Comparative Example 1 was applied as a sealing member to a watertight portion of a weather strip, and its watertight performance was evaluated by the following watertight test. The crosslinked rubber sponge material of Example 1 was used in Example 2, and the crosslinked rubber sponge material of Comparative Example 1 was used in Comparative Example 2.

[0109]

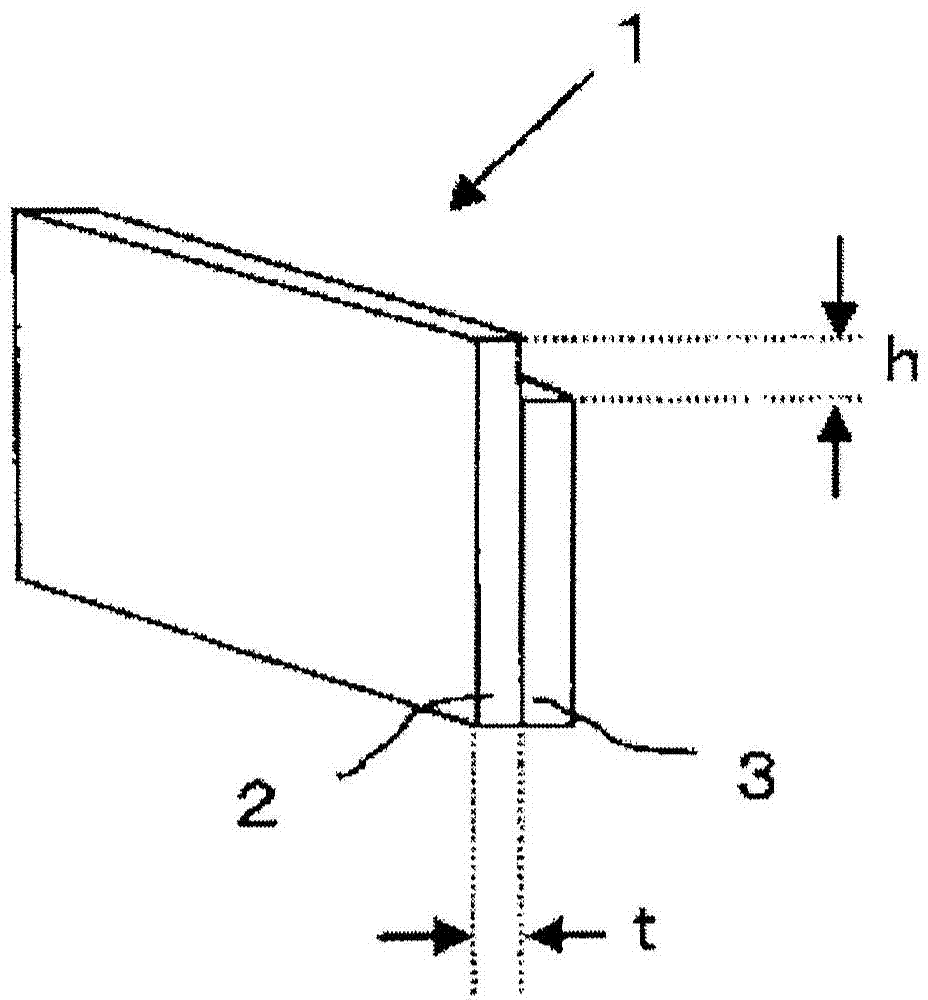

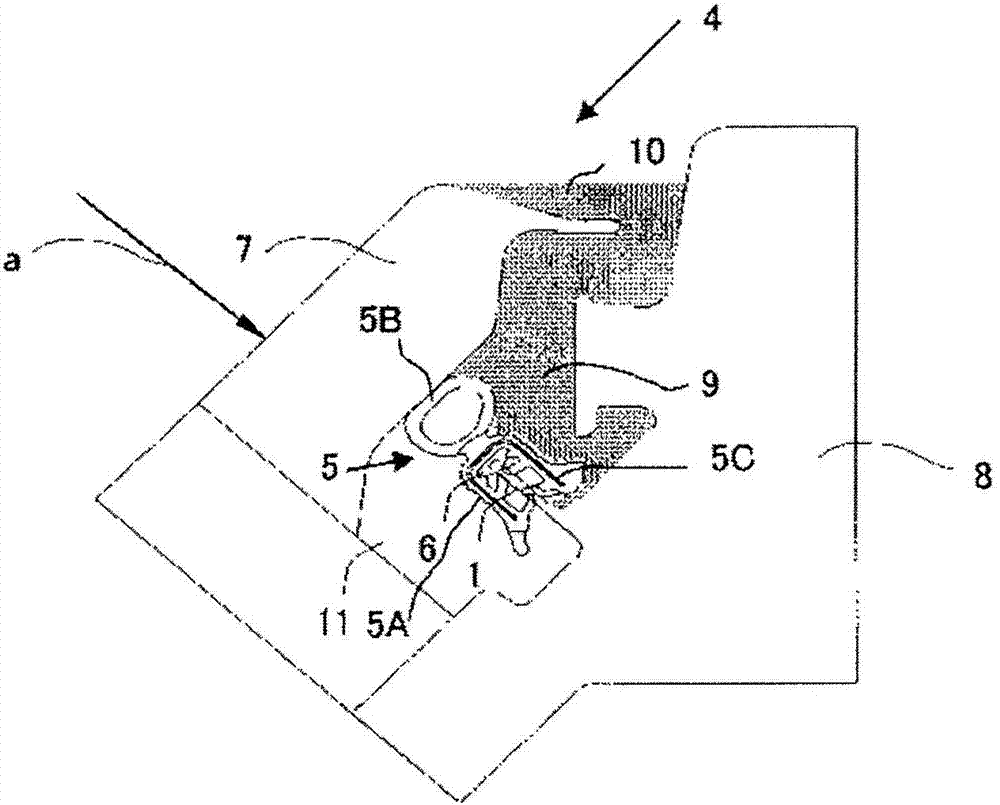

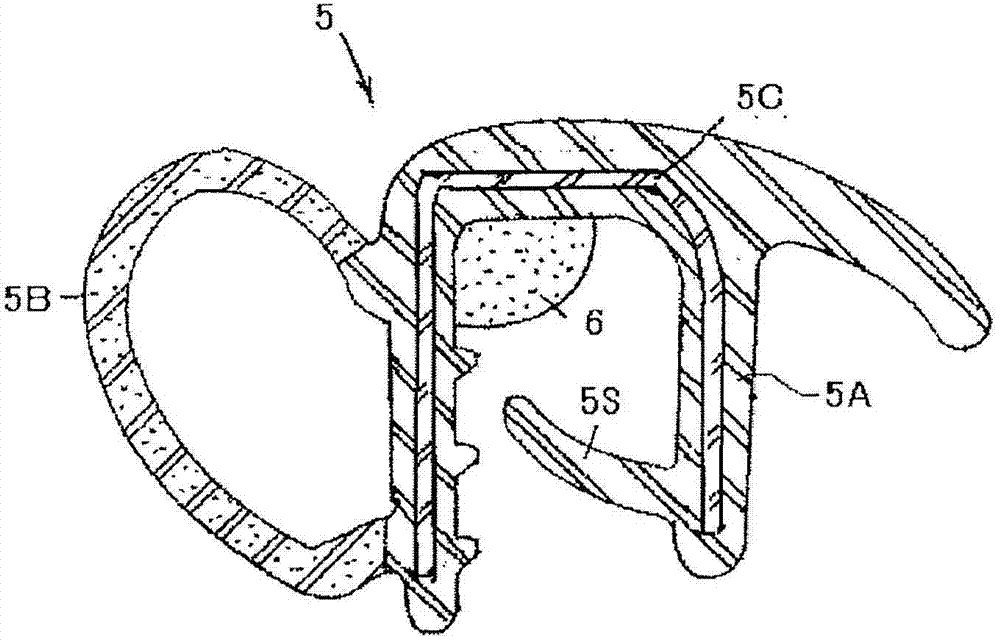

[0110] figure 2 Shows the state of the watertight test in which the structure of the rear trunk or rear door of the vehicle is reproduced. The weather stripping 5 of the automobile is fitted in the trunk or around the opening of the rear door, the weather stripping 5 has a metal or plastic core material 5C, and is also composed of a gripping portion 5A fitted onto a flange 1 formed protrudingly from the main body. Constructed with a hollow-shaped sealing member 5B having an approximately circular cross-section with a hollow in the center, whic...

Embodiment 3~6 and comparative example 3

[0119] The blending ingredients (parts by mass) described in Table 8 were kneaded to obtain a rubber composition, which was extruded into a sheet, vulcanized and foamed in a high-temperature atmosphere to produce a crosslinked rubber sponge material.

[0120] The ingredients were the same as those shown in Table 1, except that the grade (product number) of the carbon black of ingredient (d) was different from Table 1 and ingredient (c) was OBSH alone. Therefore, the terpene-based resin was YS Resin TO-105 (manufactured by Yasuhara Chemical Co., Ltd.).

[0121] Table 8

[0122]

Embodiment 3~9 and comparative example 3

(a) Olefin rubber

100

(b) Terpene resin

T

(d) carbon black

60

(e) Inorganic filler

10

(f) softener

90

(c) Blowing agent

15

(g) Cross-linking agent

1

(h) Vulcanization accelerator

8

total

284+T

[0123] The obtained crosslinked rubber sponge mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com