Acid group viscoelastic fluid and preparation method thereof as well as oil and gas reservoir or coal seam treatment method

An oil and gas reservoir and viscoelastic technology, applied in the fields of production fluids, chemical instruments and methods, and earthwork drilling, etc., can solve the problems of no viscosity, hinder surfactants, and cannot carry proppants, and achieve the increase of pores, The effect of increasing permeability and increasing pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The invention discloses a preparation method of the acid-based viscoelastic fluid described in the above technical scheme, which comprises the following steps:

[0062] Mix the surfactant, organic acid salt and water uniformly to obtain component A;

[0063] Mix formaldehyde, ammonium chloride, organic carboxylate and water uniformly to obtain component B;

[0064] The A component of 5.0wt%-15.0wt%, the component B of 15.0wt%-25.0wt% and the water of 60.0wt%-80.0wt% are uniformly mixed to obtain an acid-based viscoelastic fluid.

[0065] The selection of the raw materials in the A component and the B component is the same as the above technical solution, and will not be repeated here. The present invention does not have any restriction on the device used for mixing, and any device commonly used in the art can be used, such as a stirring pump and a fracturing truck pump.

[0066] Preferably, in the present invention, a proppant can be added when the A component, the B component a...

Embodiment 1

[0096] AI, BI and water are mixed uniformly according to 10.0kg, 20.0kg and 70.0kg to obtain acid-based viscoelastic fluid.

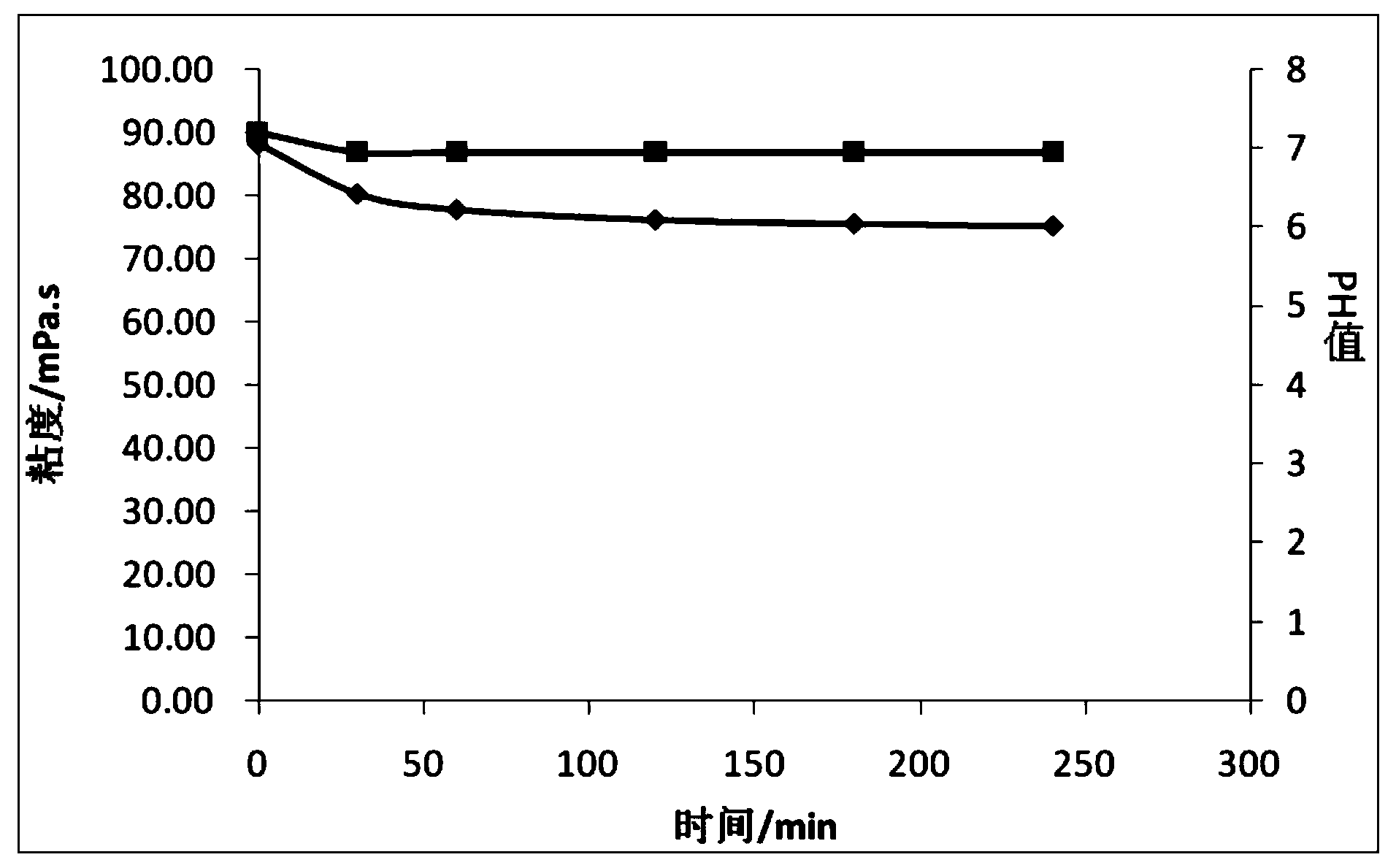

[0097] At 30°C, test the viscosity and pH changes of the acid-based viscoelastic fluid in different time periods, and see the results figure 2 , figure 2 It is the change chart of the viscosity and pH of the viscoelastic fluid obtained in Example 1 at 30°C. figure 2 in, Is the shear rate of 170S -1 The viscosity curve below, It is the pH change curve.

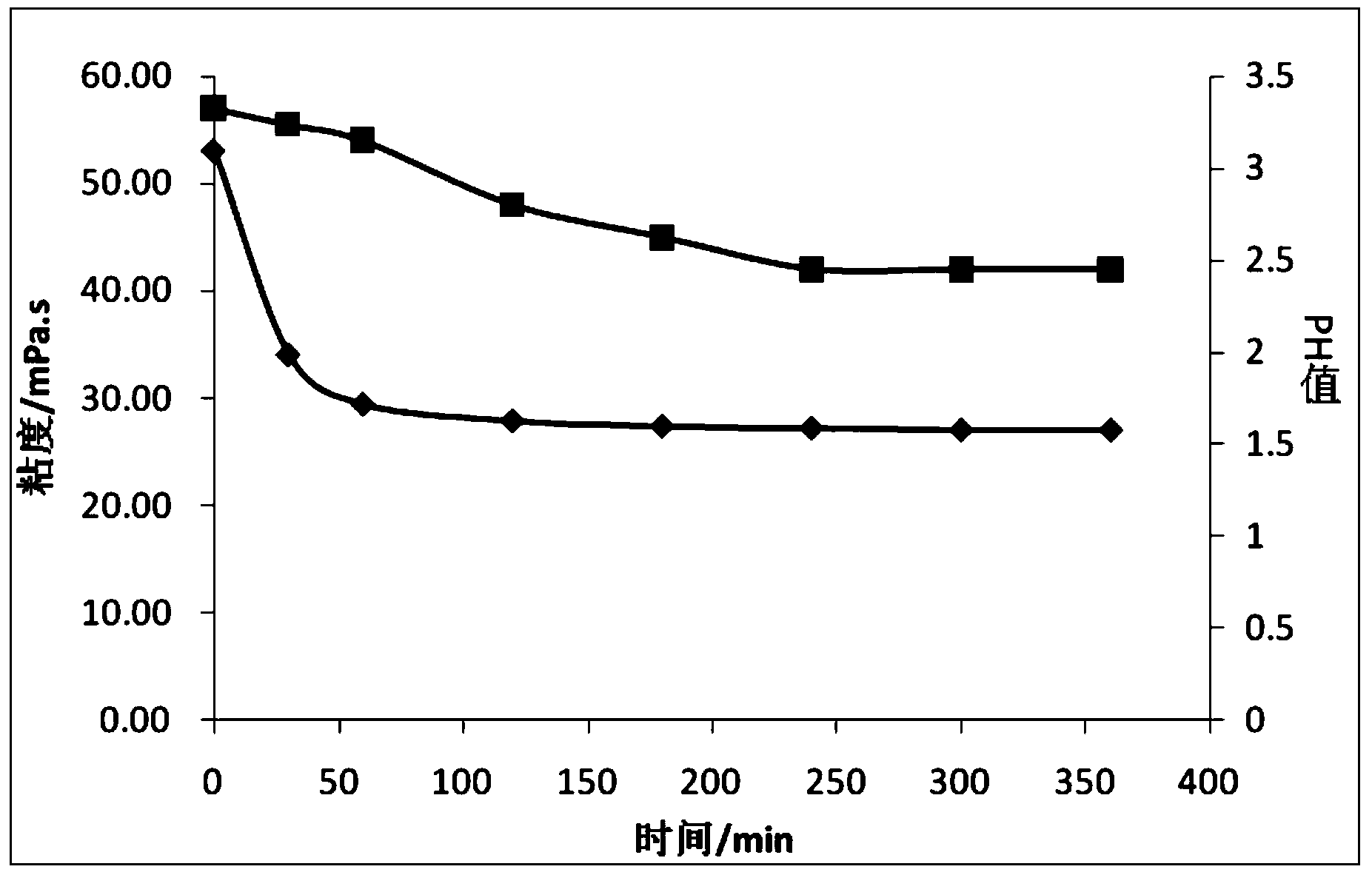

[0098] At 50℃, test the viscosity and pH changes of the acid-based viscoelastic fluid in different time periods, and see the results image 3 , image 3 It is the change chart of the viscosity and pH of the viscoelastic fluid obtained in Example 1 at 50°C. image 3 in, Is the shear rate of 170S -1 The viscosity curve below, It is the pH change curve.

[0099] After heating the obtained acid-based viscoelastic fluid at 50°C, it was evaluated by a dual-core split flow test. The permeability of the high-perm...

Embodiment 2

[0101] Mix AII, BII and water according to the ratio of 5.0kg, 25.0kg and 70.0kg to form an acid-based viscoelastic fluid.

[0102] At 30°C, test the viscosity and pH changes of the acid-based viscoelastic fluid in different time periods, and see the results Figure 5 , Figure 5 It is the change chart of the viscosity and pH of the viscoelastic fluid obtained in Example 2 at 30°C. Figure 5 in, Is the shear rate of 170S -1 The viscosity curve below, It is the pH change curve.

[0103] At 50℃, test the viscosity and pH changes of the obtained viscoelastic fluid in different time periods, see the results Image 6 , Image 6 It is the change chart of the viscosity and pH of the viscoelastic fluid obtained in Example 2 at 50°C. Image 6 in, Is the shear rate of 170S -1 The viscosity curve below, It is the pH change curve.

[0104] After heating the obtained viscoelastic fluid at 50℃, the dual core split flow test was used to evaluate the high permeability core permeability from 25.6×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com