Short-path distillation production method and short-path distiller for increasing unsaturated fatty acid content of vegetable oil

An unsaturated fatty acid and short-path distillation technology, which is applied in the field of vegetable oil refining and fractionation, can solve the problems of local crystal nuclei, increase the complexity of the actual production operation process, crystal tearing, etc., and achieve the effect of increasing the content of unsaturated fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The following is an example of processing 100 kilograms of decolorized corn oil per hour to further illustrate the short-path distillation production method for increasing the unsaturated fatty acid content in vegetable oil and the structure of the short-path still used.

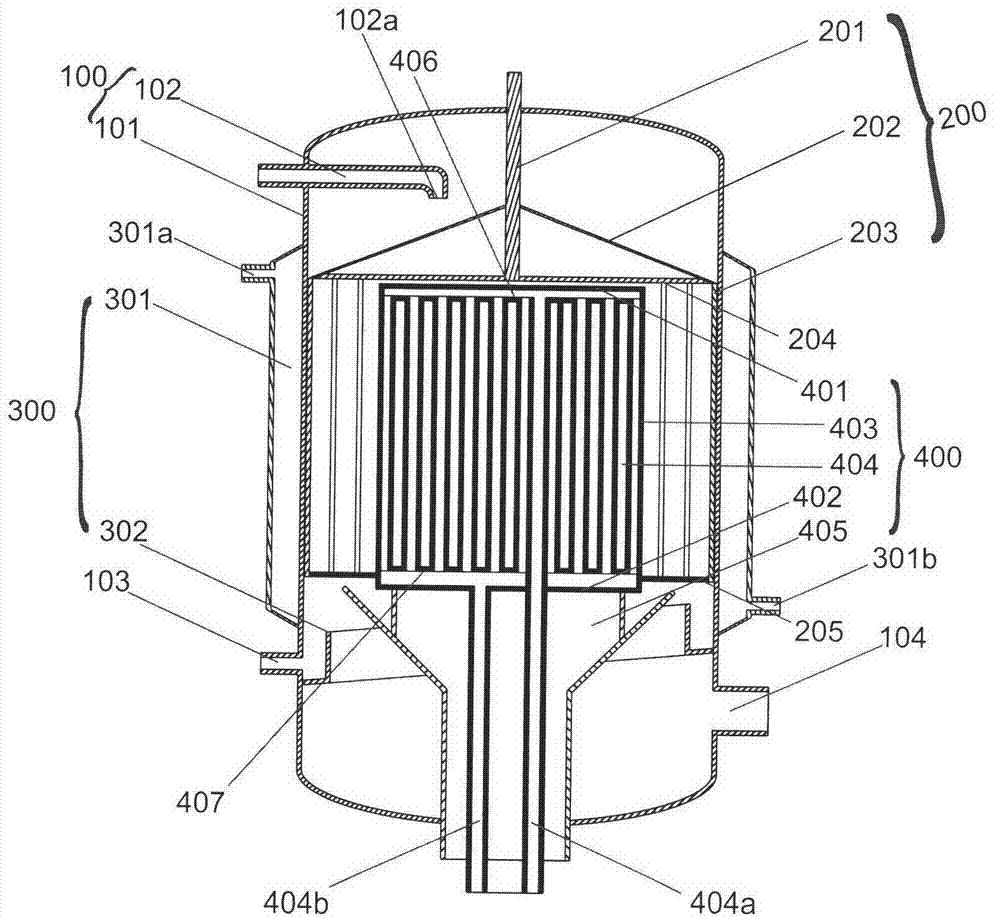

[0039] Such as Figure 1 to Figure 5 As shown, in this embodiment, the present invention provides a short path distiller, which includes a housing device 100 , a distribution device 200 , a heating device 300 and a condensing device 400 .

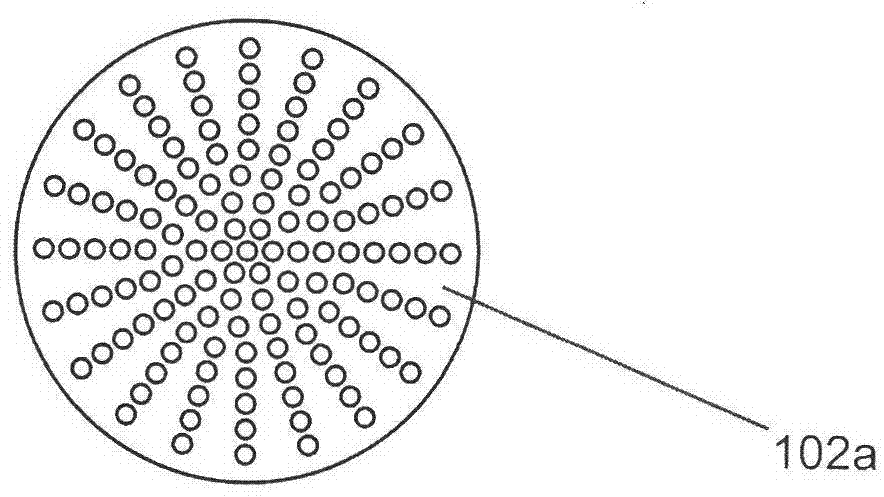

[0040] Wherein, the casing device 100 includes a cylinder body 101. In this embodiment, the cylinder body 101 is straight cylindrical, with an upper head on the top, a lower head on the lower end, and an oil inlet pipe 102 below the upper head. figure 1 with figure 2 , the oil inlet pipe 102 is certainly provided with the oil inlet pipe outlet 102a, as figure 2 As shown, in this embodiment, a number of small holes are distributed at the outlet 102a of the oil i...

Embodiment 2

[0074] Embodiment 2 continues to complete on the basis of embodiment 1, that is,

[0075] (4) Short path distillation 4:

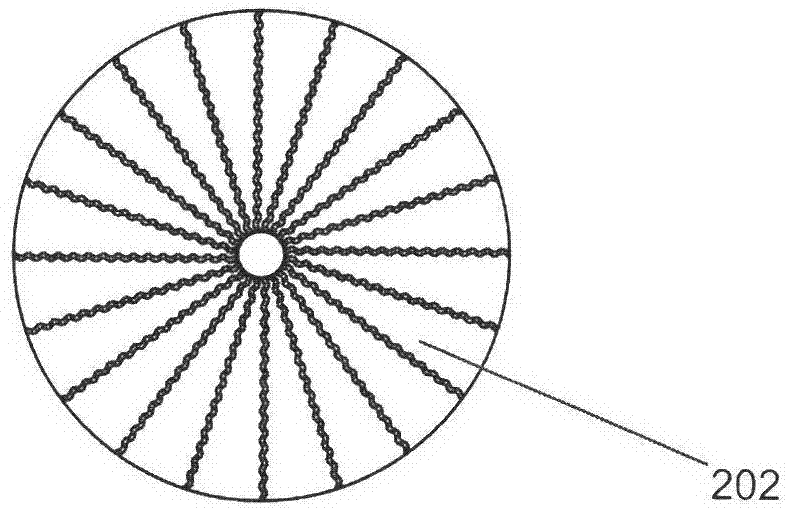

[0076] The third heavy component material in the third heavy component collection tank is heated to 240-265°C through a heat exchanger, enters the short-path still, and is evenly distributed on the heating evaporation surface through the distribution plate 202. The temperature of the heating evaporation surface is 280-316 °C, the vacuum degree is 0.1-5Pa, the fourth light component material (i.e. triglyceride rich in linoleic acid) is cooled to 30-45 °C through the condensing device 400, and flows into the fourth light component collection tank. Substances go directly to the fourth component collection tank.

[0077] After testing, the unsaturated fatty acid content in the fourth light component collection tank was 60%.

Embodiment 3

[0079] Taking the processing of 200 kg of degummed rapeseed oil per hour as an example, the short-path distillation production process for increasing the unsaturated fatty acid content in vegetable oil is further described.

[0080] This method still adopts the short path distiller of the present invention.

[0081] In the first step, the degummed rapeseed oil is heated to 160-180°C through a heat exchanger, and then enters a short-path distiller, and is evenly distributed on the heating evaporation surface through the distribution plate 202. The temperature of the heating evaporation surface is 190-200°C. With a vacuum degree of 10 Pa, the first light components (namely fatty acids and odor components) are cooled to 3-10°C through the condensing device 400, and flow into the first light component collection tank, and the first heavy components directly enter the first recombination collection tank.

[0082] In the second step, the first heavy component material in the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com