Non-dairy cream and preparation method thereof

A technology of non-dairy cream and butter, applied in the direction of edible oil/fat composition, production/processing of edible oil/fat, etc., can solve the problem of high content of saturated fatty acid in non-dairy cream, increase the content of unsaturated fatty acid, and benefit human health , Improve the effect of stability and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

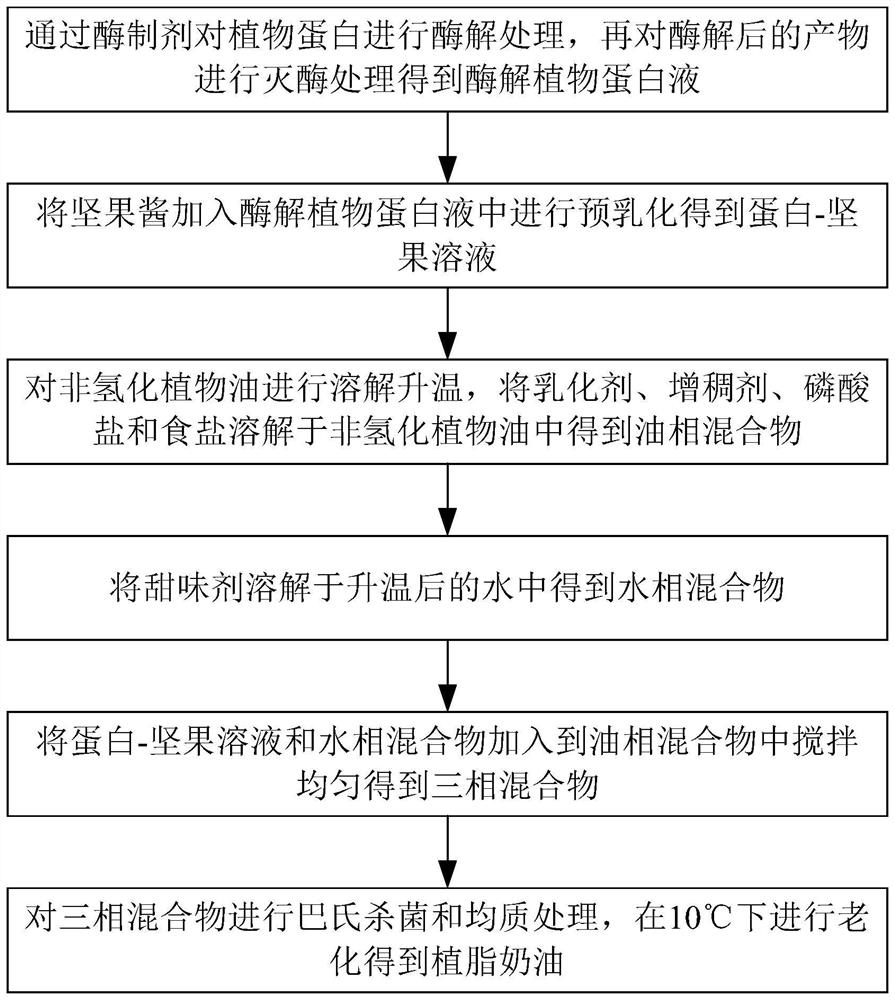

[0035] Such as figure 1 Shown, a kind of non-fat cream preparation method described in the embodiment of the present invention, the method comprises:

[0036] Enzyme hydrolyzes the plant protein for 0.5-8 hours at a temperature of 35-60°C and a pH of 3-9, and then deenzymes the enzymatically hydrolyzed plant protein at 65-100°C for 10- For 50 minutes, inhibit the activity of the enzyme preparation, eliminate the influence of the enzyme preparation on the non-dairy cream, and finally obtain the enzymatic hydrolyzed vegetable protein liquid. Through the screening, combination and condition optimization of enzyme preparations, the plant protein is enzymatically treated to obtain a moderately enzymatically hydrolyzed plant protein product (enzymatically hydrolyzed vegetable protein liquid). The enzymatically hydrolyzed vegetable protein liquid has moderate molecular weight, solubility and emulsification , foaming and freeze-thaw stability have been effectively improved, thus over...

Embodiment approach

[0046] In an optional embodiment, the enzyme preparation is one or more of pepsin, protein glutaminase, neutral protease, compound protease, bromelain, flavor protease, and papain. Applicable enzyme preparations can be selected according to the enzymatic hydrolysis environment or conditions, and other enzyme preparations other than the above enzyme preparations can be selected, which are not specifically limited in this application. The above enzyme preparation can enzymolyze the vegetable protein to obtain polypeptides and protein fragments with moderate molecular weight, and the viscosity of the obtained polypeptides and protein fragments is moderate, which improves the stability and operability of non-dairy cream.

[0047] In an optional embodiment, the vegetable protein includes soybean protein isolate, soybean protein concentrate, pea protein, wheat protein, rice protein and enzymatic hydrolysis or modified products thereof. The type of vegetable protein can be selected a...

Embodiment 1

[0053] Weigh 0.5 g of enzyme preparation (neutral protease and compound protease mixed at 1:1), enzymatically hydrolyze soybean protein isolate (concentration: 1%) at 50°C and pH 7 for 1 hour, and then at 90°C enzymatically hydrolyzed isolated soybean protein for 20 minutes to obtain enzymolyzed vegetable protein 1;

[0054] Adding 5 grams of almond paste to enzymatic vegetable protein 1, shearing and homogenizing it through a high-shear emulsification head to obtain a pre-emulsified enzymatic vegetable protein 1-almond solution;

[0055] Melt 20 grams of non-hydrogenated refined palm kernel oil and heat up to 60°C, add 0.15 grams of sucrose fatty acid ester, 0.15 grams of sodium stearoyl lactylate, 0.3 grams of Tween 60, 0.05 grams of propylene glycol fatty acid ester; hydroxypropyl methylcellulose 0.5 grams of prime, 0.3 grams of xanthan gum, 0.1 grams of carrageenan, 0.1 grams of locust bean gum, 0.1 grams of dipotassium hydrogen phosphate, and 0.2 grams of salt are added t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com