Equipment and method for rapid repair of refractory brick falling off in cross section of blast furnace hot air duct

A technology of hot air pipes and refractory bricks, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of large repair area, large consumption of manpower, large cooling water consumption, and long maintenance cycle, so as to facilitate rapid setting and production, and improve filling The effect of compactness and reducing the difficulty of construction

Active Publication Date: 2016-03-02

GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Once there is a problem with the hot air system, the general situation is to adopt grouting, digging and patching the shell, external water cooling and other methods to deal with it. The grouting method cannot completely fill the cracks or defects of the refractory masonry at the high temperature point. In severe cases, the grouting material will enter the pipeline. Inside or at the tuyere, serious blockages are caused and the entire hot air duct is scrapped; the outer shell is cut and plastered to repair, the repair area is large, and a lot of manpower is required. It needs to be shut down for 20-30 days for maintenance. All high-temperature resistant materials are removed and rebuilt. The maintenance cycle long and expensive

The external water cooling method can not completely cover the reddened area, but can only partially relieve the reddened phenomenon, and cannot fundamentally solve the problem. At the same time, the cooling water consumption is large, and a large amount of hot steam will be generated, which poses a certain safety hazard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0056] Embodiment: Take the No. 2 blast furnace of Jiuquan Iron and Steel Works as an example for specific description.

[0057] A. Temperature monitoring

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

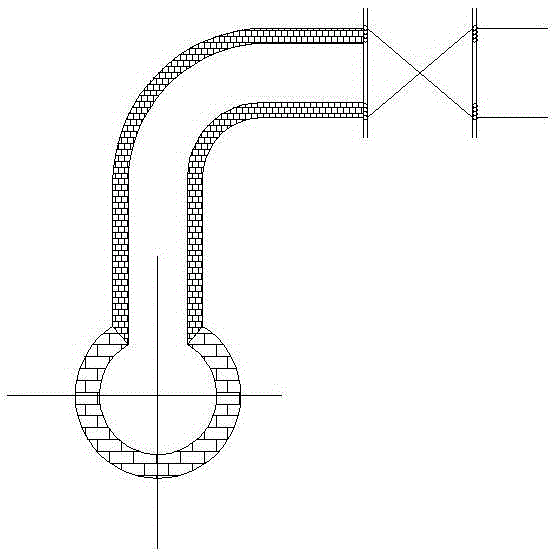

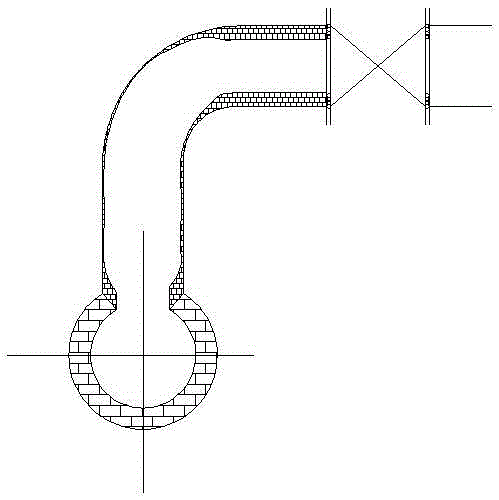

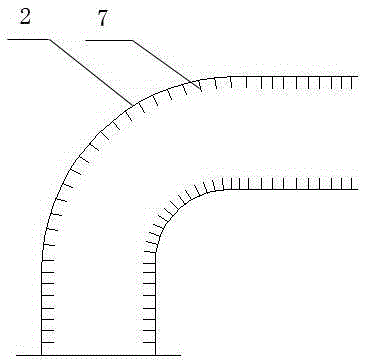

The invention belongs to the technical field of metallurgical equipment, and in particular discloses rapid blast furnace hot-air pipeline cross section refractory brick dropping repairing equipment and method, being applicable to rapid repairing of dropping and damage of refractory bricks inside cross position pipelines of blast furnace hot-air pipelines, hybrid wind tubes, hot-air branch tubes, surrounding tubes and the like under working conditions such as thermal shock. A hybrid wind tube mold consists of a bent tube section mold, a splicing section mold and a main tube hanging mold, wherein a bent tube section is firstly prefabricated and a splicing section is secondly cast, and the bent tube section and the splicing section are integrally welded by using a splicing method, so that the construction difficulty is greatly alleviated, the repairing working period is greatly shortened to be 3-4 days, and furthermore the time for stopping the furnace is shortened and the cost is lowered; anchor rivets are arranged inside the bent tube section mold, the anchor rivets are Y-shaped, and the opening angle is 120 degrees; a plurality of anchor rivets are arranged on the inner side of the bent tube section mold, and the anchor rivets are arranged in a grid-shaped structure. Due to the anchor rivets, a casting material can be firmly fixed, and the casting material is solid and durable after being condensed and formed, so that the service life is greatly prolonged.

Description

technical field [0001] The invention belongs to the technical field of metallurgical equipment, in particular to a rapid repair device and method for refractory bricks falling off at the cross section of a blast furnace hot blast pipeline, which is suitable for refractory bricks in the crossing positions of blast furnace hot blast pipelines and air mixing pipes, hot blast branch pipes, surrounding pipes, etc. Rapid repair of masonry falling off and damage under thermal shock and other working conditions. Background technique [0002] As we all know, the blast furnace hot air pipeline for ironmaking blast furnace transports the hot air heated by the hot blast furnace, that is, hot air. The refractory bricks at the intersection with the branch pipe and inside the pipe elbow are prone to fall off during use. [0003] At present, the refractory materials of the hot air system pipelines of domestic hot blast stoves are all designed with refractory bricks. The difference is that ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21B7/00C21B5/00

Inventor 胡海波张勇

Owner GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com