Thermoelectric composite treatment method suitable for reducing residual stress of metal materials

A metal material and residual stress technology, which is applied in the field of material processing to achieve the effects of overcoming long heating time, simple device and reducing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The following will take 20CrMnTi material as an example to illustrate the method of eliminating stress by using the method of the present invention.

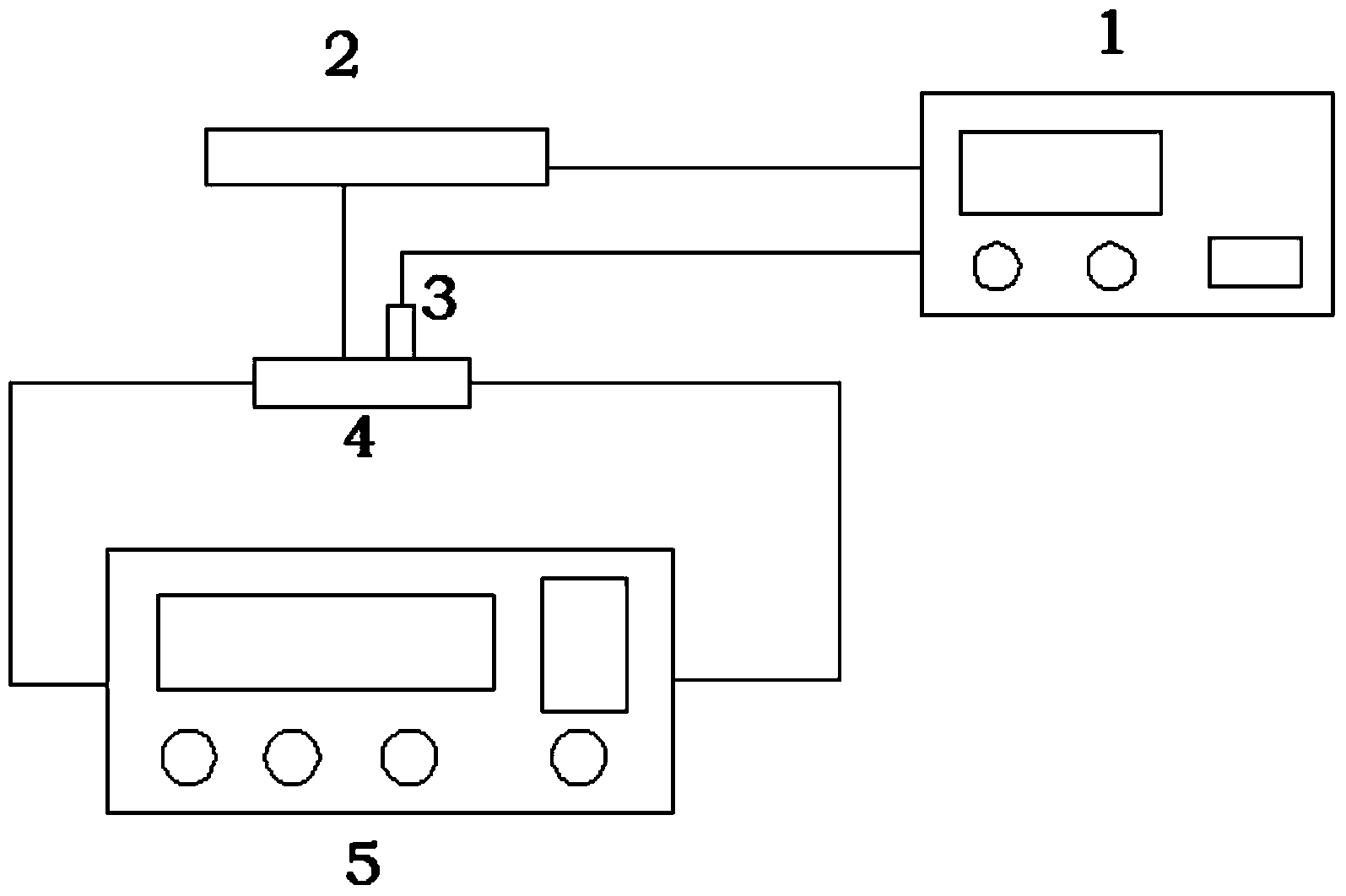

[0034] Step 1. Prepare the sample, make the gear material 20CrMnTi that has been ground and burnt on the surface into a metal workpiece 4 with a size of 15mm*15mm*10mm, and polish the two sides of the metal workpiece 4 to be polished with sandpaper , so that more effective electrode contact points are exposed on both sides of the metal workpiece 4 to be processed;

[0035] Step 2. Place the metal workpiece 4 to be processed at both ends of the electrodes of the pulse power supply. The two sides of the metal workpiece 4 to be processed are directly connected to the pulse power supply through wires. Paste to reduce contact resistance;

[0036] Step 3, place the infrared heating tube 2 near the surface of the metal workpiece 4 to be processed, and coat the place where the thermocouple 3 is in contact with the metal workpiec...

Embodiment 2

[0042] In the following, the bearing steel GCr15 material will be taken as an example to illustrate the method for eliminating its stress by using the method of the present invention.

[0043] Step 1, prepare the sample, make the bearing steel GCr15 after grinding into a metal workpiece 4 to be processed with a size of 15mm*15mm*10mm, and polish the two sides of the metal workpiece 4 to be processed with sandpaper to make the metal to be processed More effective electrode contact points are exposed on both sides of the workpiece 4;

[0044] Step 2. Place the metal workpiece 4 to be processed at both ends of the electrodes of the pulse power supply. The two sides of the metal workpiece 4 to be processed are directly connected to the pulse power supply through wires. Paste to reduce contact resistance;

[0045] Step 3, place the infrared heating tube 2 near the surface of the metal workpiece 4 to be processed, and coat the place where the thermocouple 3 is in contact with the m...

Embodiment 3

[0051] In the following, the rail material U71Mn will be taken as an example to describe the method of eliminating stress using the method of the present invention.

[0052] Step 1, prepare the sample, make the rail material U71Mn after grinding into a metal workpiece 4 to be processed with a size of 15mm*15mm*10mm, and polish the two sides of the metal workpiece 4 to be processed brightly with sandpaper to make the metal workpiece to be processed More effective electrode contact points are exposed on both sides of the workpiece 4;

[0053] Step 2. Place the metal workpiece 4 to be processed at both ends of the electrodes of the pulse power supply. The two sides of the metal workpiece 4 to be processed are directly connected to the pulse power supply through wires. Paste to reduce contact resistance;

[0054] Step 3, place the infrared heating tube 2 near the surface of the metal workpiece 4 to be processed, and coat the place where the thermocouple 3 is in contact with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com