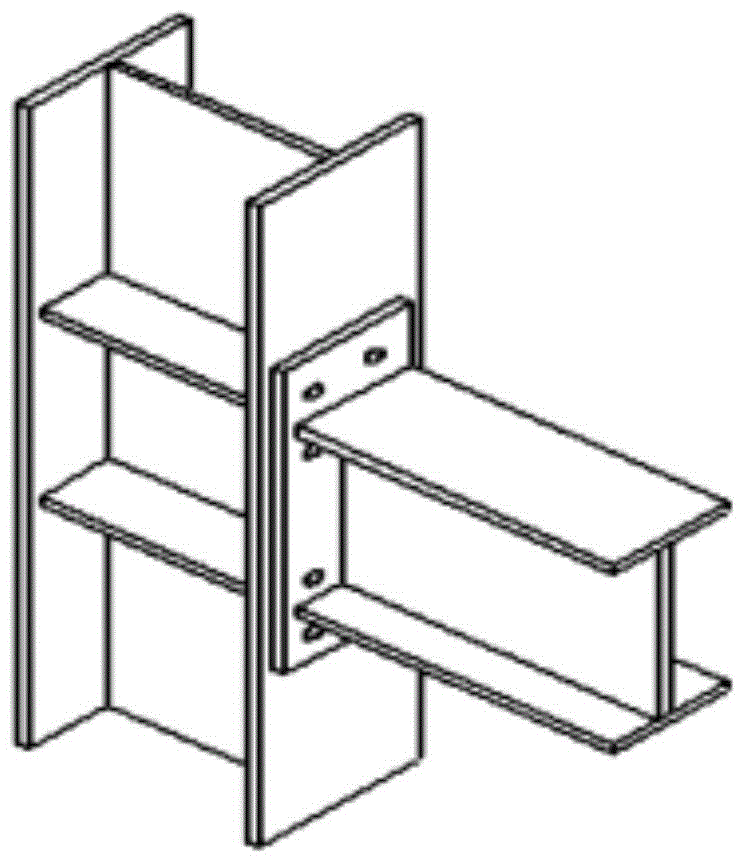

Cast steel modular connectors and connecting nodes for beam-to-column connections in steel structures

A beam-column connection and steel structure technology, applied in building construction, construction, etc., can solve problems such as insufficient bearing capacity and damage of bolts, and achieve the effect of reducing construction costs and repairing work quickly and easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

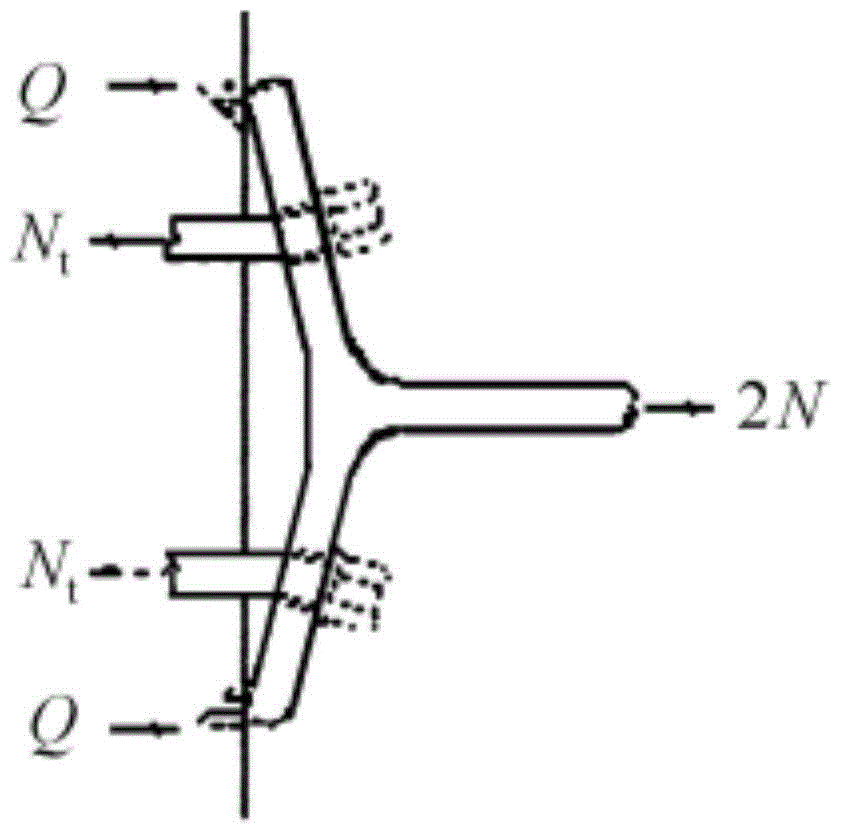

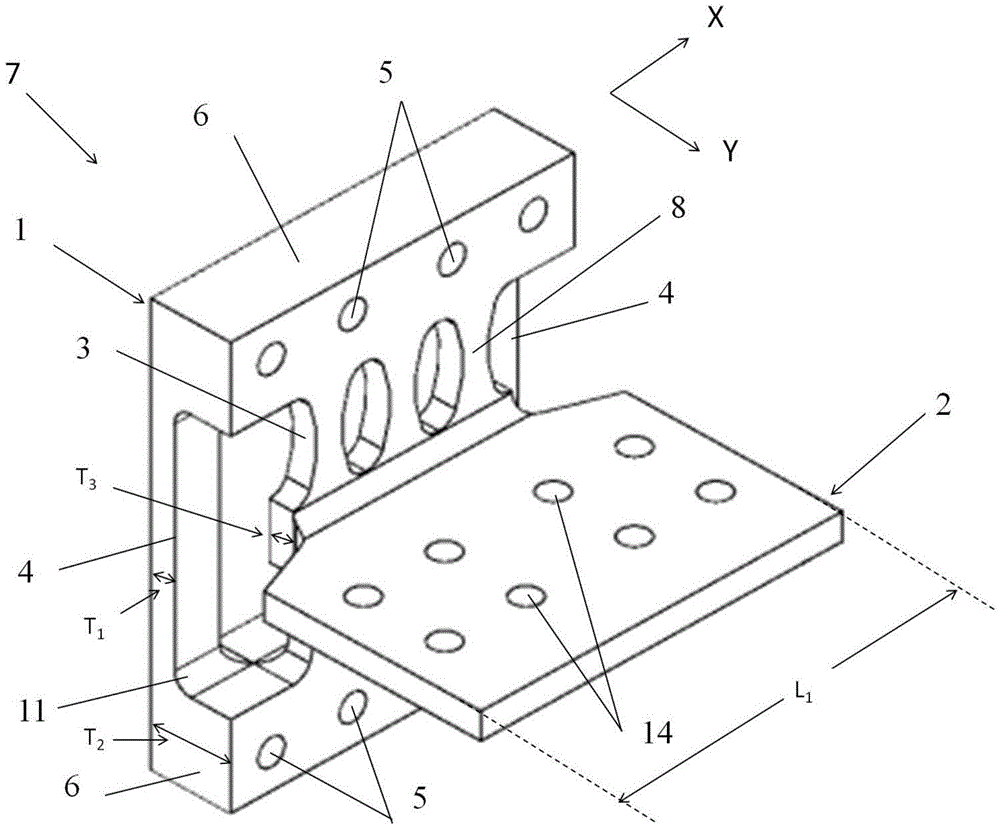

[0034] This embodiment provides a cast steel modular connector for beam-column connection of steel structures, which is used to provide seismic support for beam-column structures composed of steel columns and steel beams. The steel beams are parallel to the horizontal ground, and the steel columns are perpendicular to the horizontal ground. Such as image 3 As shown, the cast steel modular connector 7 includes a vertical limb 1 fixedly connected to a steel column and a horizontal limb 2 fixedly connected to a steel beam. The vertical limb 1 and the horizontal limb 2 are integrated into a horizontally placed In this way, the connection between the vertical limb 1 and the horizontal limb 2 does not contain a weld seam, so that the cast steel modular connector has high impact toughness and easy quality assurance. The cast steel modular connector is symmetrical about the center plane of the transverse limb 2 along its own thickness direction and the center plane of the transverse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com