Combined-type movement mechanism

A kinematic mechanism and composite technology, which is applied in the direction of transmission, mechanical equipment, belt/chain/gear, etc., can solve the problems of large volume, weight, power consumption, and complex mechanism structure, and achieve small weight and power consumption, and structural Simple, with stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

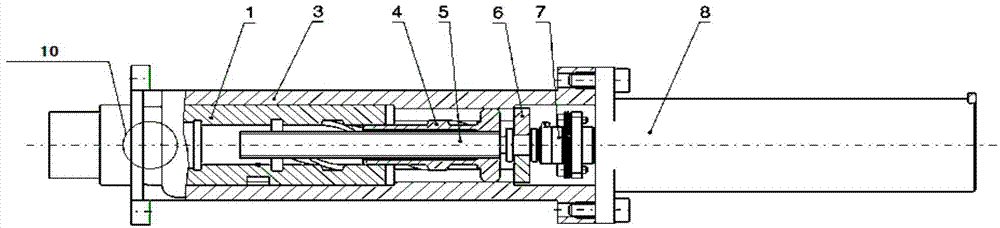

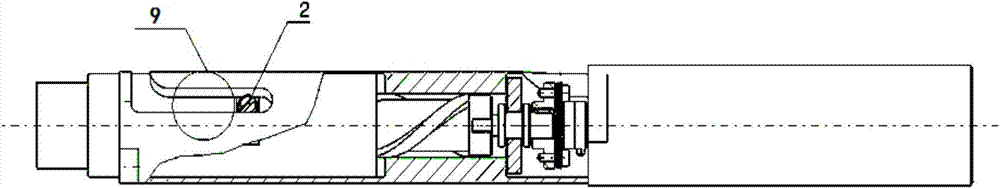

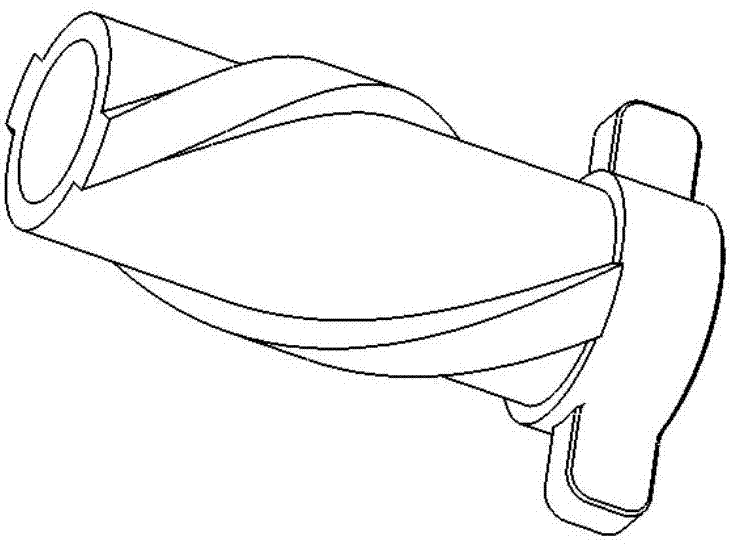

[0026] A composite motion mechanism, including a displacement output shaft 1, a limit pin 2, a mechanism housing 3, a screw rod 4, a screw rod 5, a bearing 6, a coupling 7, and a rotating drive element 8, wherein the displacement output shaft 1 Radial mounting holes 13 are processed on the outer circumference, and spiral grooves 12 are processed on the inner surface. The mechanism casing 3 is a hollow cylindrical structure. Connecting flanges are processed on the outer circumferences of the two ends of the cylinder respectively. The hollow part of the cylinder is divided into Small-diameter part and large-diameter part, two axisymmetric axial grooves 11 are processed on the inner surface of the small-diameter part, and limited grooves are processed on the large-diameter part. There is an annular boss on which two radially extending symmetrical lugs are processed, rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com