Refrigerating system

A refrigeration system and refrigerant technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high energy consumption, high energy saving requirements, poor practicability, etc., achieve low power, reduce initial investment, and good safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

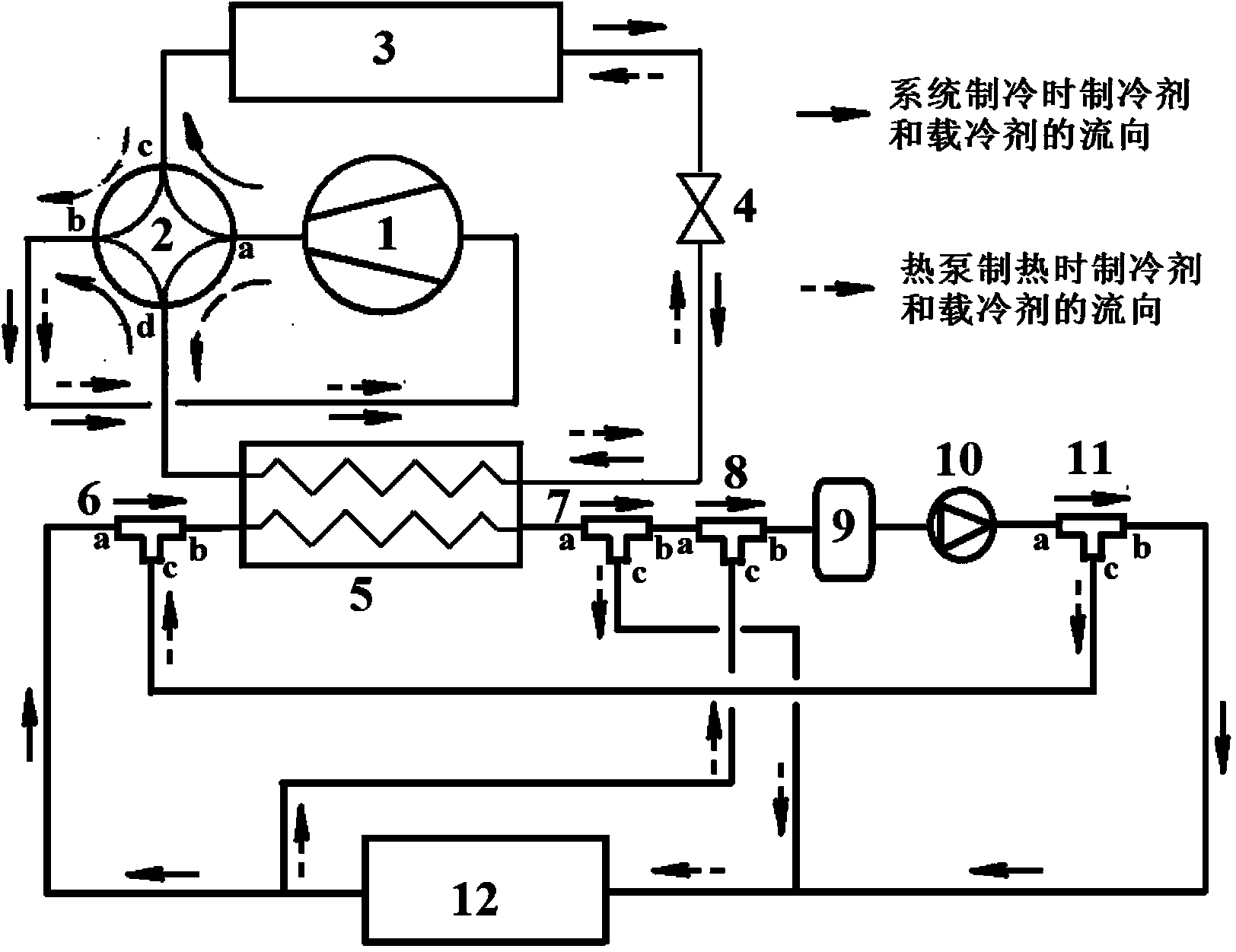

[0036] Hereinafter, the present invention will be further described in detail by taking a heat pump air-conditioning refrigeration system that can realize both cooling and cooling, and heat pump heating, using propane (HC-290) as the refrigerant and water as the refrigerant as an example.

[0037] like figure 1 As shown, during refrigeration, the high-temperature and high-pressure HC-290 vapor discharged from the refrigeration compressor 1 enters the first heat exchanger 3 through the a-c interface of the four-way reversing valve 2, dissipates heat to the ambient medium, and cools down and condenses into high-pressure HC-290. The liquid is depressurized into gas-liquid two-phase HC-290 with a temperature of about 10°C through the throttling mechanism 3, enters the second heat exchanger 5 to absorb heat and evaporate into low-pressure HC-290 vapor, and then passes through the four-way reversing valve. The d-b interface of 2 is sucked and compressed by the refrigeration compress...

example 2

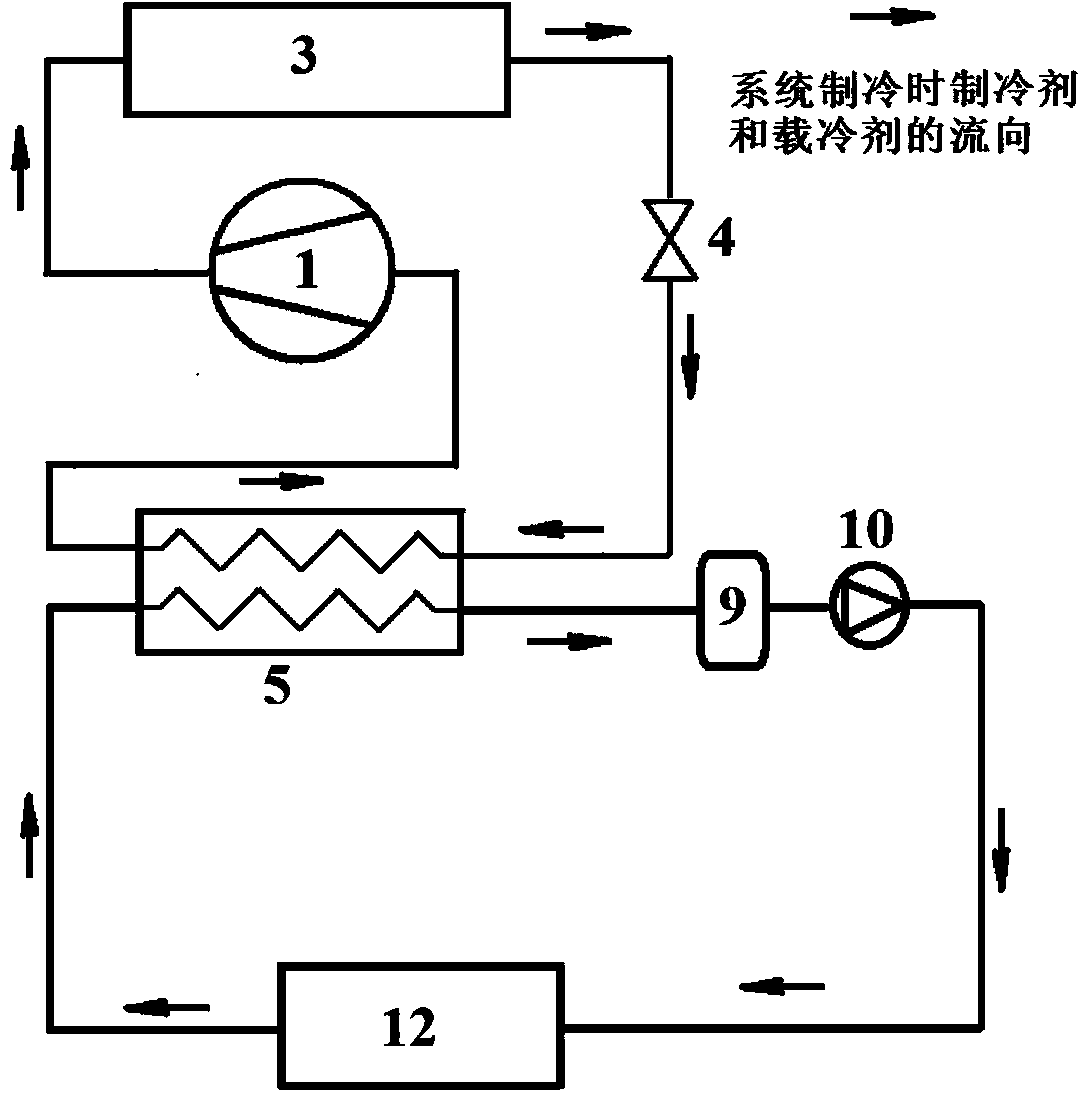

[0041]Hereinafter, the present invention will be further described in detail by taking a single-cooling air-conditioning refrigeration system that only realizes cooling and cooling, uses propane (HC-290) as the refrigerant, and uses water as the carrier refrigerant as an example.

[0042] like figure 2 As shown, the high-temperature and high-pressure HC-290 vapor discharged from the refrigeration compressor 1 enters the first heat exchanger 3, dissipates heat to the ambient medium, reduces the temperature and condenses into a high-pressure HC-290 liquid, and then passes through the throttling mechanism 3 to reduce the pressure to a temperature of 10 The gas-liquid two-phase HC-290 at about ℃ enters the second heat exchanger 5 to absorb heat and evaporate into low-pressure HC-290 vapor, which is inhaled and compressed by the refrigeration compressor 1 and enters the next refrigeration cycle. In the second heat exchanger 5, the water vapor is cooled by heat absorption, condense...

example 3

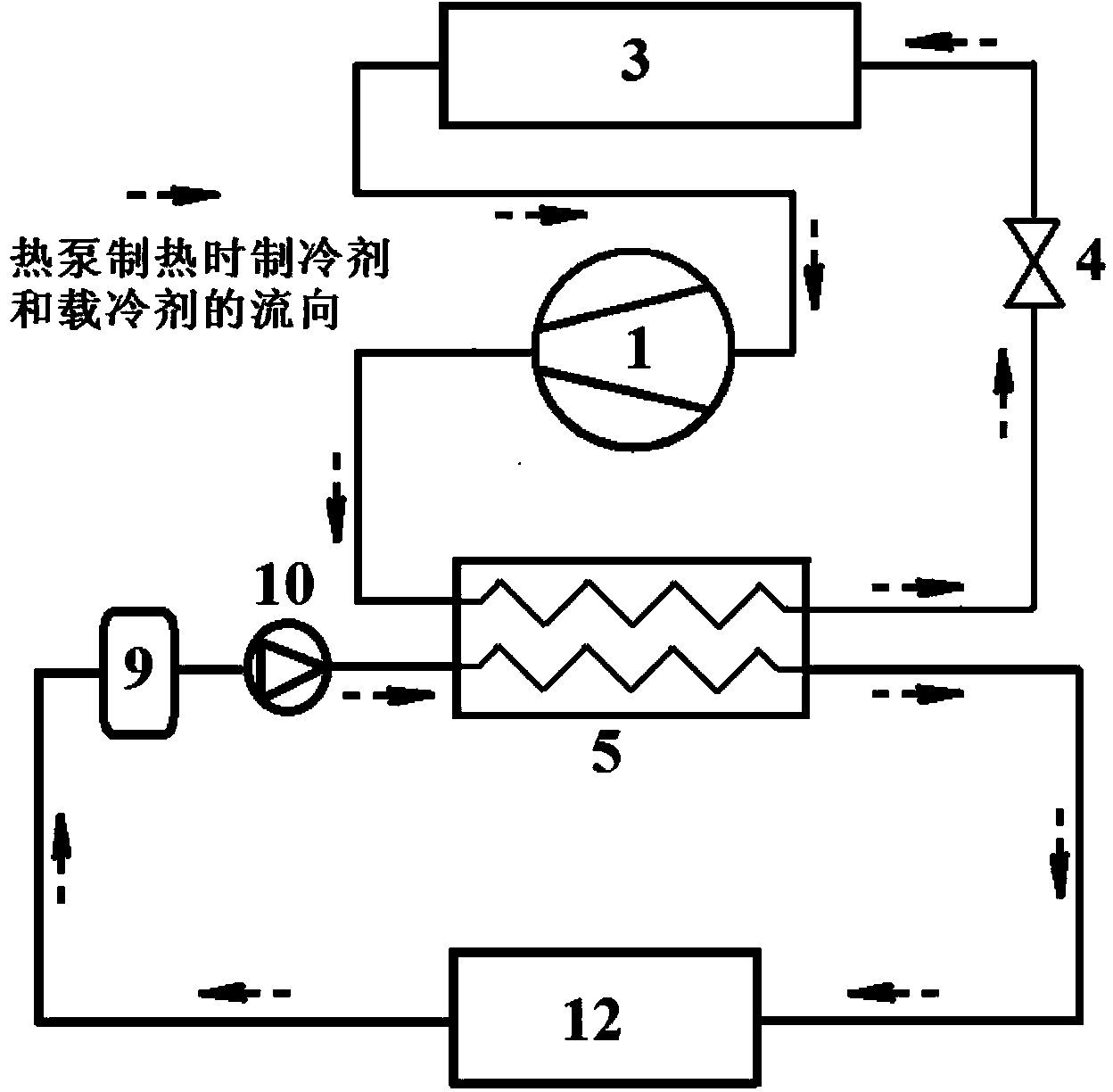

[0045] The present invention will be described in further detail below by taking an example of a heating-type air-conditioning and refrigeration system that only implements heat pump heating, uses propane (HC-290) as the refrigerant, and uses water as the carrier refrigerant.

[0046] like image 3 In the refrigeration system provided by the present invention, the high-temperature and high-pressure HC-290 steam discharged from the refrigeration compressor 1 enters the second heat exchanger 5, dissipates heat to the liquid water, reduces the temperature and condenses into high-pressure HC-290 with a temperature of about 40°C. The liquid is depressurized into low-temperature and low-pressure gas-liquid two-phase HC-290 through the throttling mechanism 3, and enters the first heat exchanger 3 to absorb heat from the ambient medium and evaporate into low-pressure HC-290 vapor, which is inhaled by the refrigeration compressor 1. , compress, and enter the next heat pump heating cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com