Method for rapidly preparing high specific surface area graphene oxide

A high specific surface area, graphene technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of prolonging freeze-drying treatment time, lengthy preparation cycle, improving vacuum degree, etc., achieving environmental friendliness and simple process. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using the Brodie method, 2g of natural flake graphite (80 mesh sieve) is oxidized to obtain graphite oxide with a carbon-to-oxygen ratio (C / O)=4.2; configure tert-butanol / water mixing volume ratio of 0.3:1 for freeze-drying medium, and stir and disperse graphite oxide in tert-butanol / water mixed solvent to obtain a uniformly dispersed suspension. Place the graphite oxide suspension in the cold trap of a freeze dryer for rapid freezing at -55°C, then turn on the vacuum pump to keep the vacuum in the freezing chamber below 30Pa, and keep this state for 45 hours until the solvent is completely sublimated, and then you can get dry Sponge-like graphene oxide ( figure 1 ).

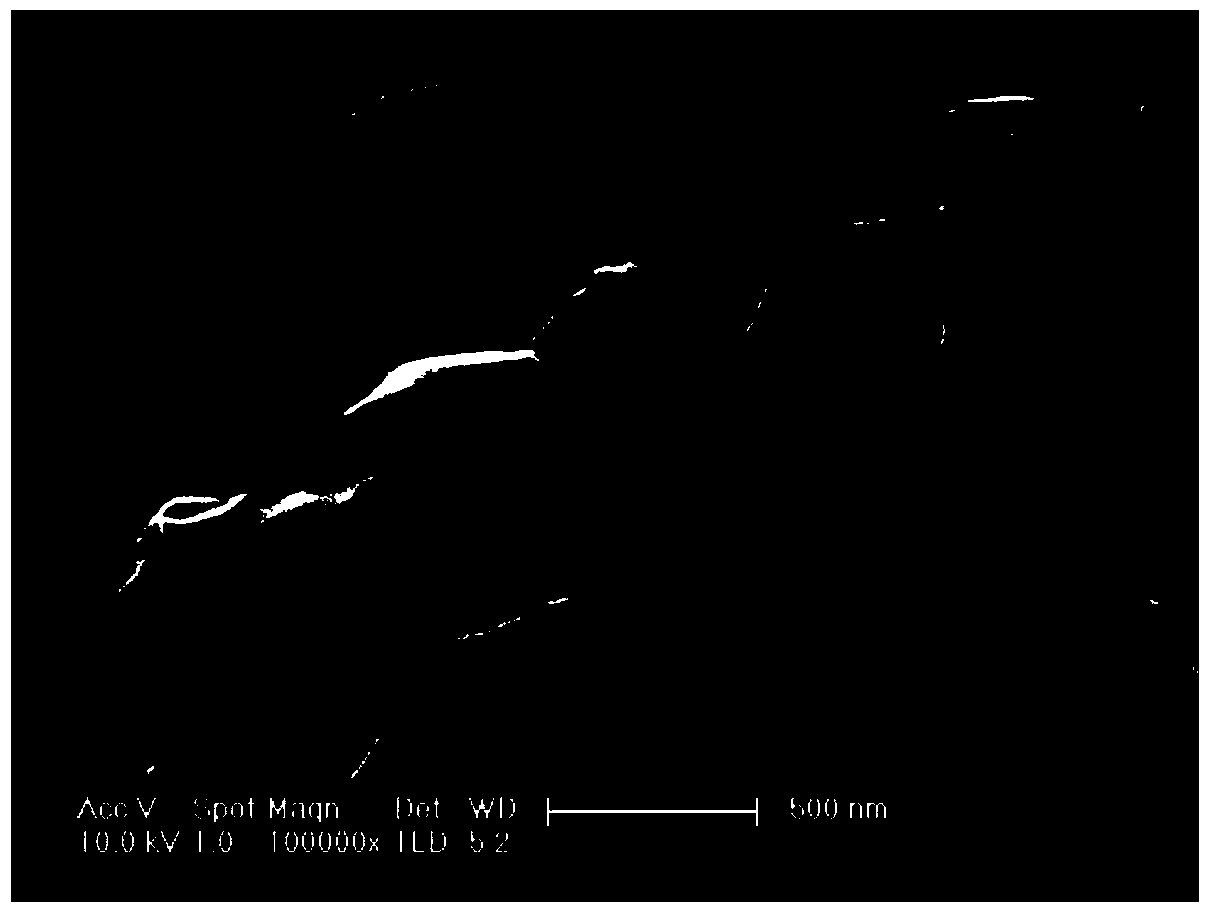

[0037] The observation of the morphology by scanning electron microscope found that the three-dimensional cross-linked structure of graphene oxide was intact without collapse, the carbon ring sheets were fully peeled off, and the structure was loose ( figure 2 ). Using the specific surface area and po...

Embodiment 2

[0039] Using the Hummers method, 5g of natural flake graphite (100 mesh sieve) is oxidized to obtain graphite oxide with a carbon-to-oxygen ratio (C / O)=3.6; configure tert-butanol / water mixing volume ratio of 1:1 for freeze-drying medium, and stir and disperse graphite oxide in tert-butanol / water mixed solvent to obtain a uniformly dispersed suspension. Place the graphite oxide suspension in the cold trap of a lyophilizer for rapid freezing at -40°C, then turn on the vacuum pump to keep the vacuum in the freezing chamber below 50 Pa, and keep this state for 37 hours until the solvent is completely sublimated, and then you can get dry Sponge-like graphene oxide.

[0040] The observation of the morphology by scanning electron microscope found that a large number of irregular cross-linked holes run through the three-dimensional structure of graphene oxide, and the cross-linked structure is intact without collapse. Using the specific surface area and porosity analyzer, the BET sp...

Embodiment 3

[0042] Using the Staudenmaier method, 3g of artificial graphite powder (200 mesh sieve) is oxidized to obtain graphite oxide with a carbon-to-oxygen ratio (C / O)=4.1; configure tert-butanol / water mixing volume ratio of 4:1 for freeze-drying medium, and stir and disperse graphite oxide in tert-butanol / water mixed solvent to obtain a uniformly dispersed milky mixed solution. Put the graphite oxide emulsion in the cold trap of the lyophilizer for rapid freezing at -15°C, then turn on the vacuum pump to keep the vacuum in the freezing chamber below 50Pa, and keep this state for 46 hours until the solvent is completely sublimated, and the dry sponge can be obtained graphene oxide.

[0043] The observation of the morphology by scanning electron microscope found that the graphene oxide product maintained a good three-dimensional stacked structure hole, and the cross-linked structure was intact without collapse. Using the specific surface area and porosity analyzer, the BET specific s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com