Method for measuring sheet welding residual stress

A technology of residual stress and measurement method, applied in the direction of measurement force, measurement device, instrument, etc., to achieve the effect of high reliability, low equipment cost, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

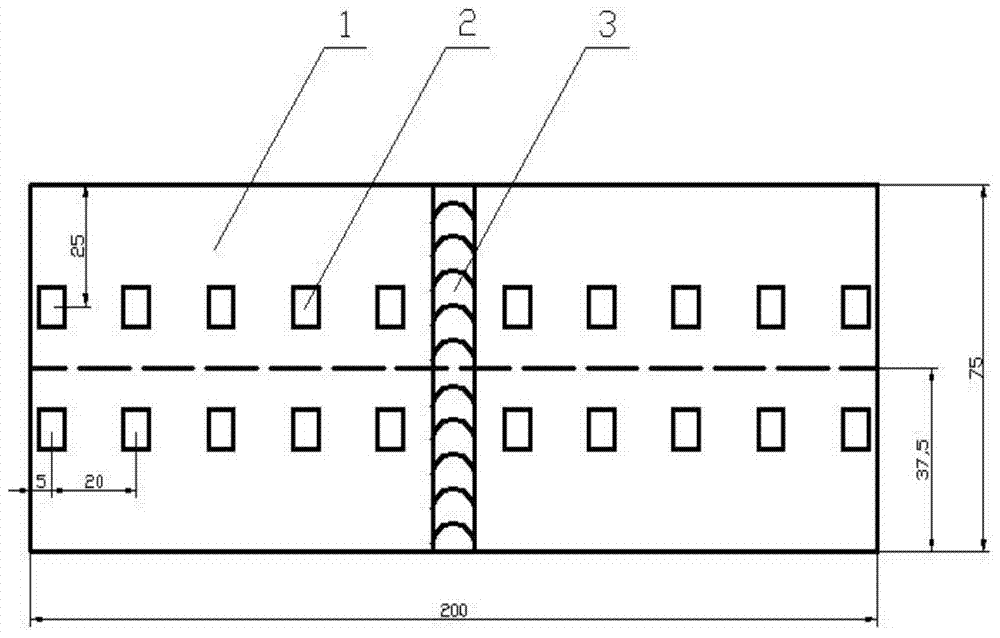

[0023] A Q235 steel plate with a size of 200mm×75mm×2.5mm was welded by tungsten inert gas shielded arc welding method without adding wire.

[0024] a. Paste two rows of symmetrically distributed BF350 high-precision resistive strain gauges 2 on the weldment 1, so that they are distributed on two straight lines 25mm away from the two long sides. The distance between the two rows of strain gauges is 25mm, and the same row The adjacent BF350 high-precision resistance strain gauges 2 are separated by 20mm, and the direction of the strain grid is consistent with the direction of the weld 3. Record the initial readings of the strain gauges, and adjust the initial readings of the two sets of strain gauges to zero with a pre-adjusted balance box. Number the two columns of strain gauges 2 from left to right;

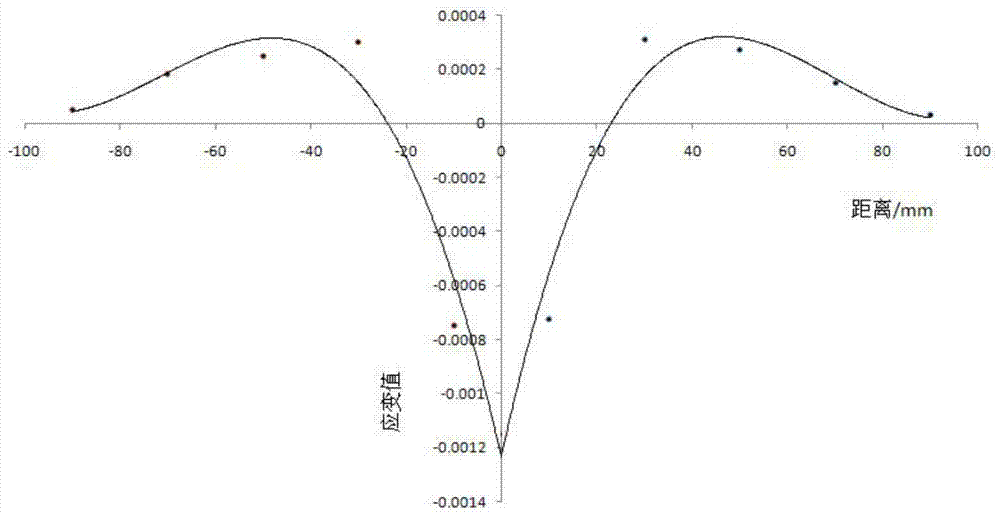

[0025] b. Use the high-precision AW310T slow-moving wire cutting machine (wire diameter: Ф0.3mm) to cut the weldment 1 into two parts of the same size along the direction perpen...

Embodiment 2

[0038] The blind hole method is used to test the residual stress measurement of thin plate welding. The material is also Q235 steel plate welded by tungsten inert gas shielded arc welding method without wire surfacing, and the size remains unchanged.

[0039] A, each strain gauge sticking point among the embodiment 1 is used as the test site, and the position of each measuring point is marked with a marking pen;

[0040] b. Paste BE120-2CA-K type 3-way strain rosettes on each measuring point;

[0041] c. Connect all 3-way strain rosettes to the YC-III strain measuring instrument, input the calibrated release coefficient into the instrument, and perform zero adjustment on the instrument;

[0042] d. Use the ZDL-1 drilling instrument to drill holes at the measuring points in sequence, and drill holes to a depth of 2mm at a slow speed;

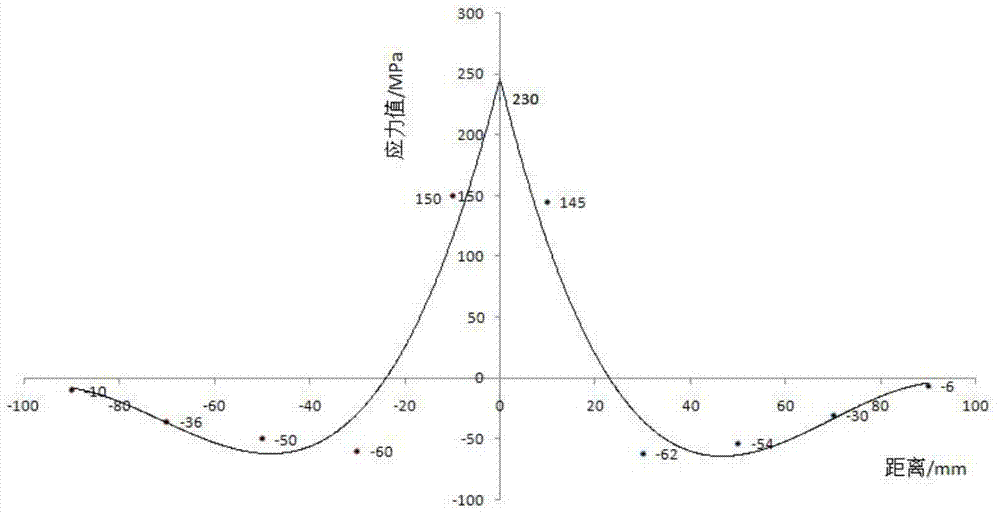

[0043] e. After the drilling is completed, the instrument will automatically calculate the stress value from the measured strain value and reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com