Quick correcting system and method for static performance of pressure sensor

A pressure sensor, static performance technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of rarely found, high cost, difficult efficiency, etc., to reduce key influencing factors, high calibration efficiency, high calibration accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

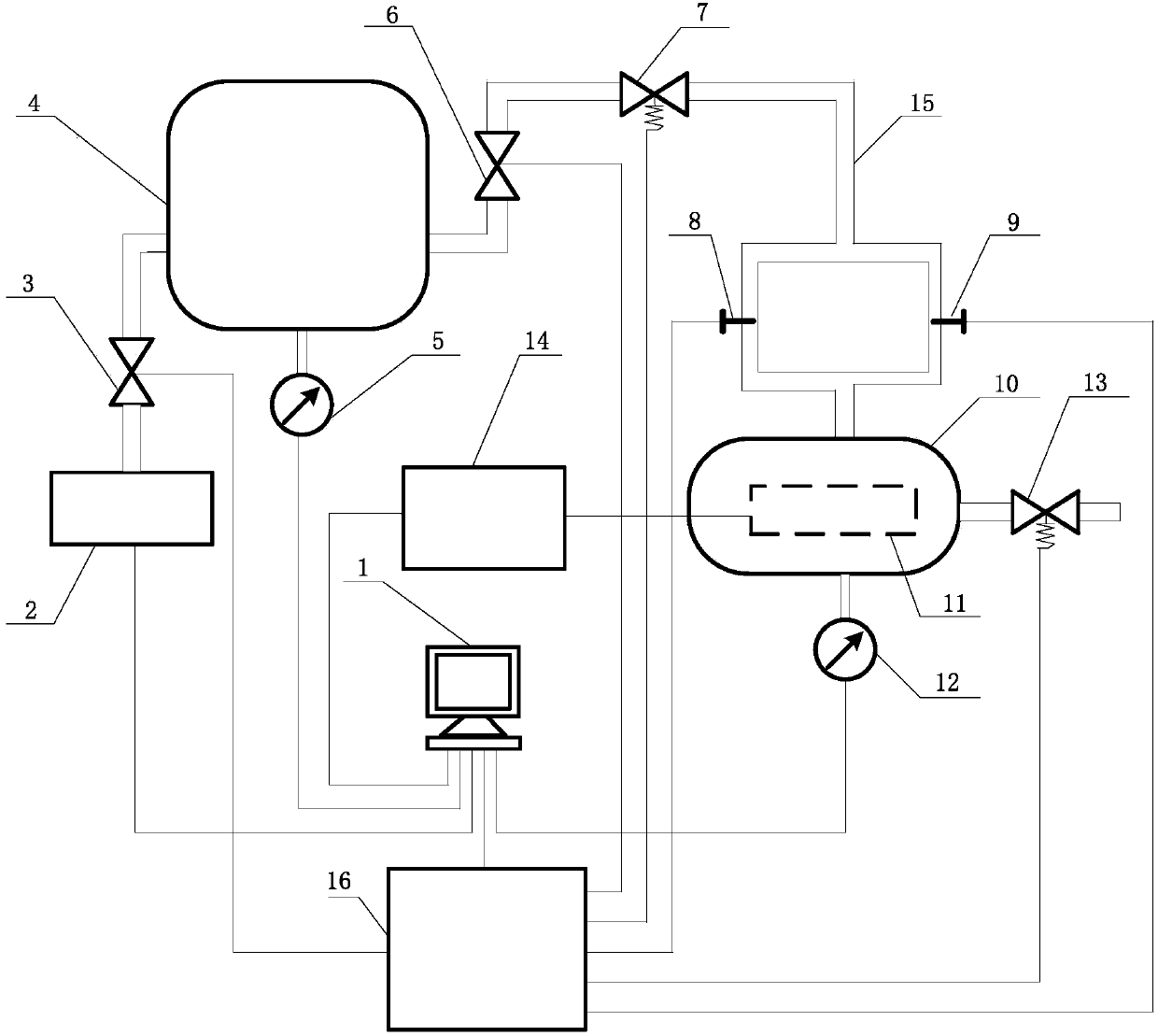

[0013] Pressure sensor static performance quick calibration system such as figure 1 As shown, during calibration, the computer 1 opens the inlet pressure valve 3 and closes the outlet pressure valve 6, and then starts the pressure pump 2 to fill the large-capacity gas storage tank 4 with pressure. After reaching the set pressure range of the computer 1, the large-capacity gas storage tank 4 The large chamber pressure controller 5 on the computer sends a stop signal to the computer 1, and the computer 1 stops the pressure pump 2 and closes the inlet pressure valve 3; The valve adjustment 9 makes the boosting process in the small-cavity pressure vessel 10 present a first-order change, the calibrated pressure sensor 11 placed in the small-cavity pressure vessel 10 bears the pressure of the first-order change, and the high-speed data co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com