X-ray focus tester based on slit method

An X-ray, tester technology, applied in the field of non-destructive testing, to achieve the effect of high radius accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

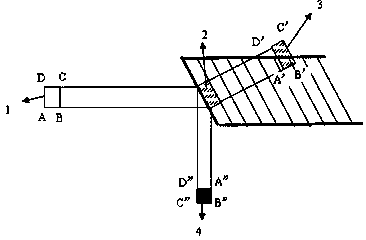

[0016] Embodiment one: if figure 1 The test layout diagram of the X-ray focal point detection experiment is shown. A slit diaphragm is arranged on the X-ray path. The slit is formed by sandwiching a layer of plexiglass plate with a thickness of d between two heavy metal tungsten plates of sufficient thickness. d is much smaller than the spot size, the thickness of the tungsten plate can sufficiently attenuate the X-rays, and the black density distribution image i(x) with distinct layers will be received on the subsequent film.

[0017] Depend on figure 1 The geometric relationship of D 0 = [DL 1 -d(L 2 + L 1 )] / L 1 The experimental layout is to arrange a step device on the X-ray path, and place the film close to the step. During the experiment, a blurred step image will be obtained on the receiving film, and the step image contains the fuzzy information of the film system.

Embodiment 2

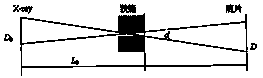

[0018] Embodiment 2: The focus size mainly depends on the shape and size of the cathode filament of the X-ray tube. The part of the anode target hit by electrons is called the actual focus; the projection of the actual focus on the ray window is called the effective focus, such as figure 2 , assuming that the electron beam is approximately parallel to the anode, and then using the principle of pinhole imaging to project the actual focus onto the film, the size of the effective focus can be obtained from the projection size on the negative according to the relevant formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com