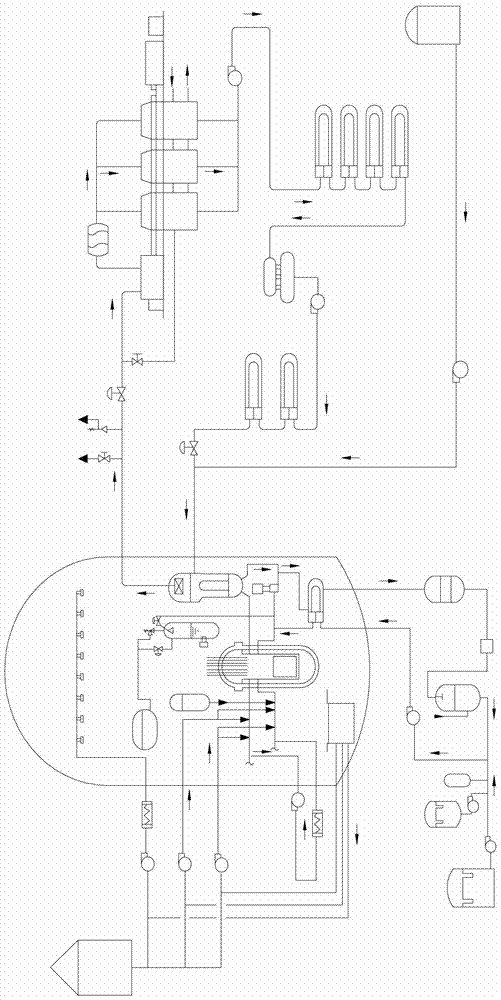

Safety injection system of nuclear power plant and cleaning method for cleaning its injection pipeline

A technology of safe injection and cleaning method, which is applied to the field of safe injection system in nuclear power plants and the cleaning of injection pipelines thereof, can solve the problems of lax valve closure, influence of sealing performance, leakage of check valve 13, etc., so as to facilitate pressure boosting , the effect of increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

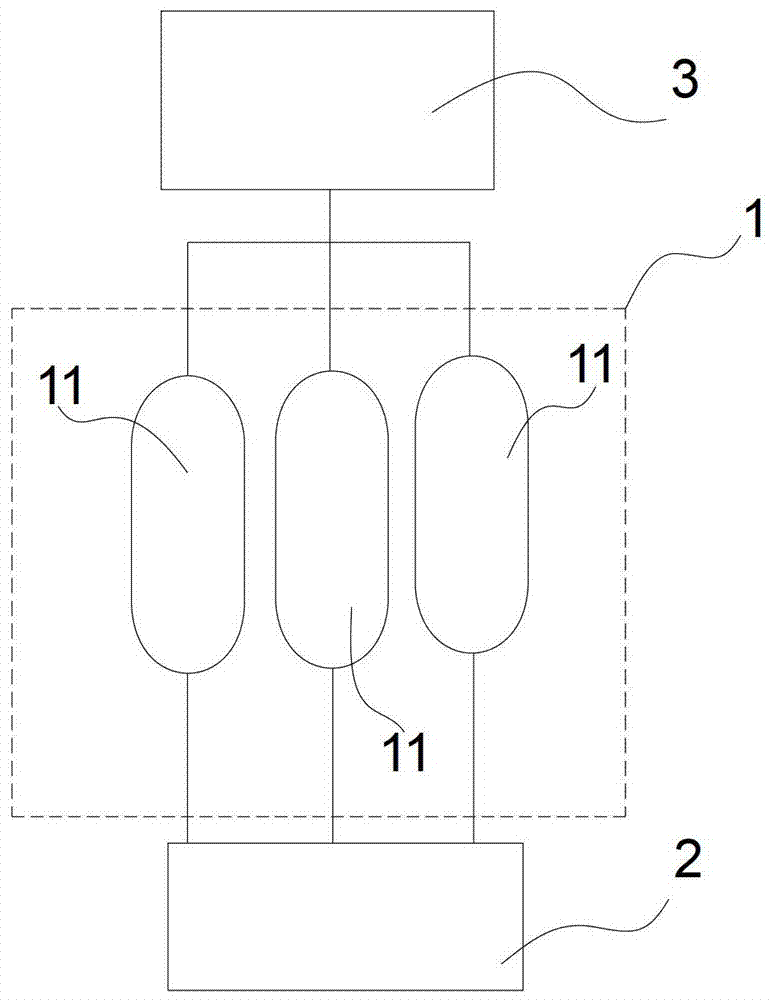

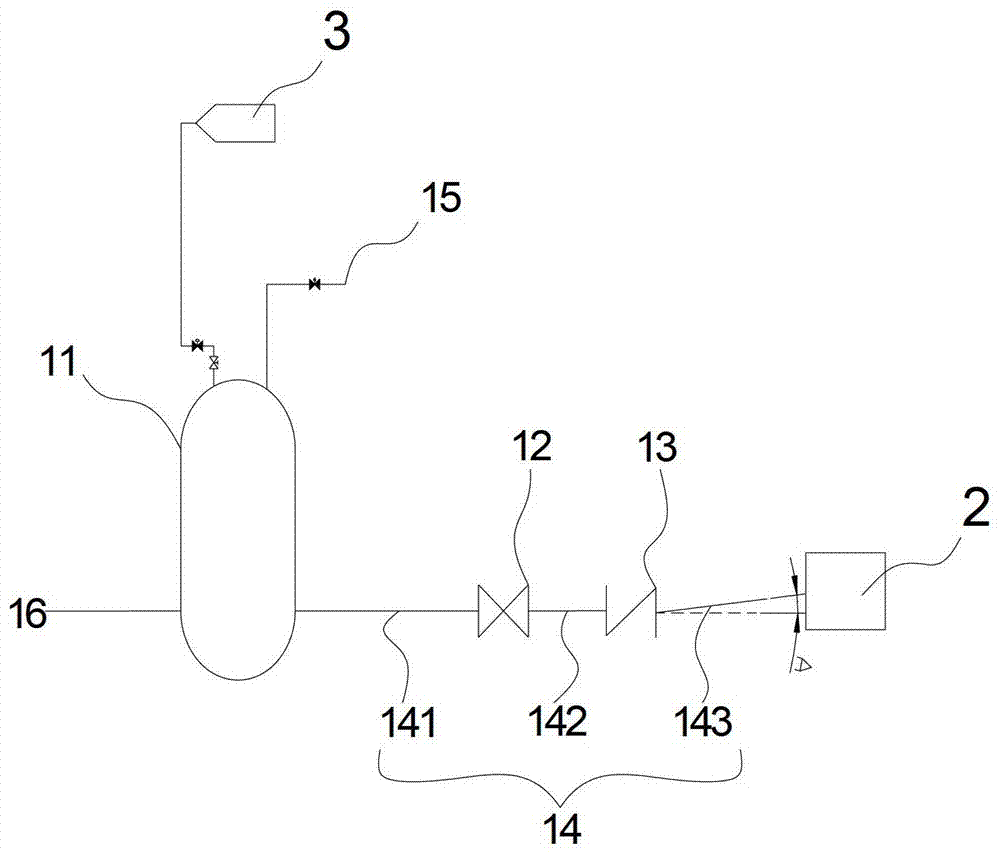

[0052] Please refer to Figure 4 The nuclear power plant safety injection system in the first embodiment includes a plurality of safety injection tanks 11 arranged side by side, and each safety injection tank 11 has a cavity for storing a fluid medium.

[0053] The safety injection tank 11 communicates with the reactor coolant system 2 through the injection pipeline 14, an isolation valve 12 is installed at the end of the injection pipeline 14 close to the safety injection tank 11, and an isolation valve 12 is installed at the end of the injection pipeline 14 close to the reactor coolant system passage 2. There is a check valve 13. The isolation valve 12 can control the opening and closing of the injection pipeline 14 , and the check valve 13 is mainly used to prevent the reactor coolant system 2 from forming backflow into the safety injection tank 11 and avoid damage to the safety injection tank 11 and other equipment.

[0054] The injection pipeline 14 includes a first pipe...

Embodiment 2

[0066] This embodiment 2 provides a specific method implemented according to the inventive concept of the injection pipeline cleaning method of the present application, so as to eliminate the small angle A formed between the check valve 13 and the horizontal in the prior art, and it is easy to be in the valve of the check valve 13. The accumulation of corrosion products at the disc makes the valve disc of the check valve 13 not close tightly, resulting in leakage at the check valve 13 and affecting its sealing performance.

[0067] Please refer to Figure 5 , the cleaning method shown in the second embodiment includes the following steps:

[0068] Firstly, the gas pressurizing device 4 is temporarily connected with the safety injection tank 11, and the high-pressure gas is prepared to be supplied into the safety injection tank 11. At this time, a certain amount of fluid medium is stored in the safety injection tank 11. Because the fluid medium flushing the injection pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com