Medium voltage fire resistant cable for airport terminal

A fire-resistant cable and terminal building technology, applied in the field of fire-resistant cables, can solve problems such as inability to resist fire, achieve excellent electrical performance, good fire-resistant characteristics, and solve the effects of electrical performance and fire-resistant characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

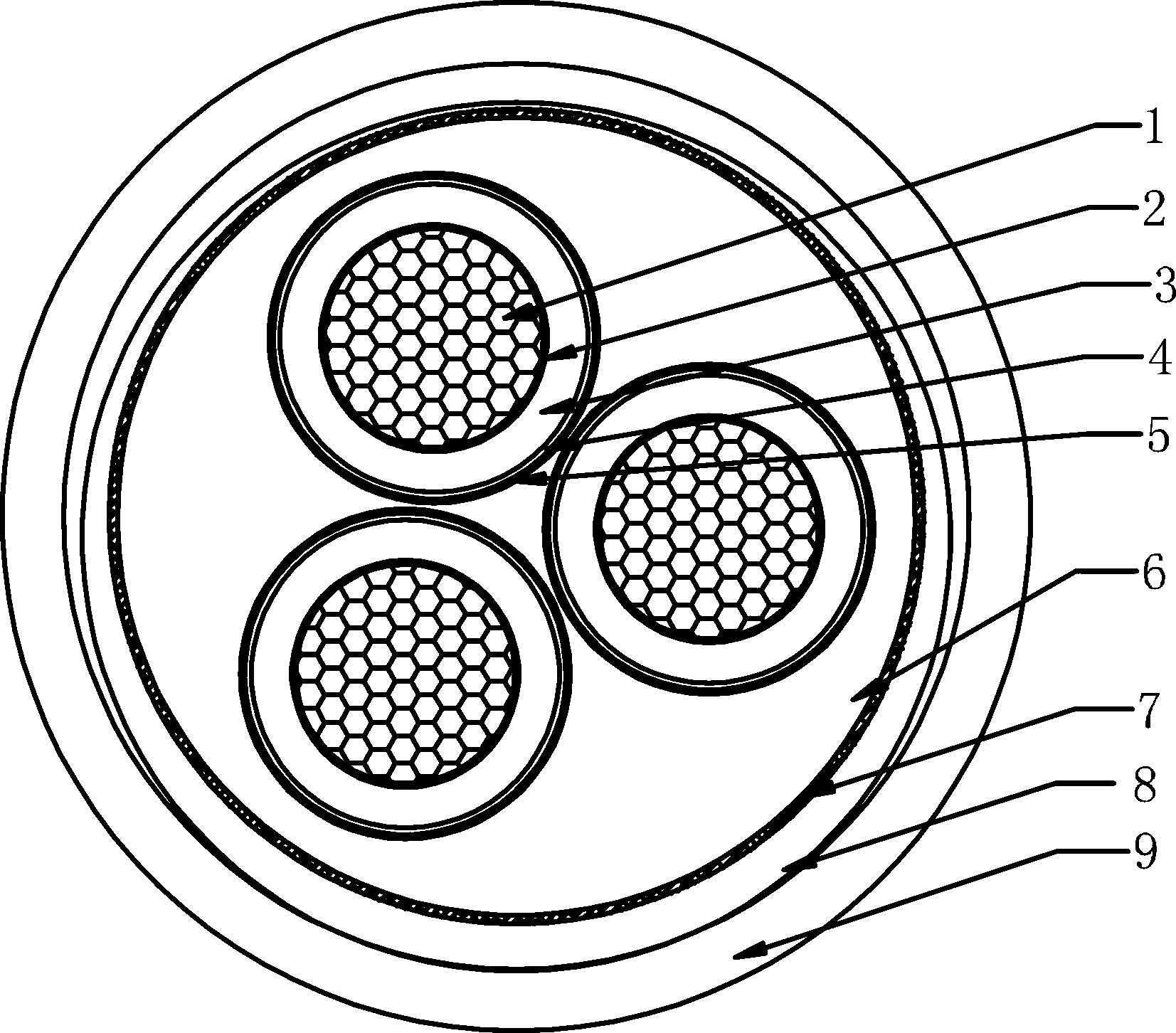

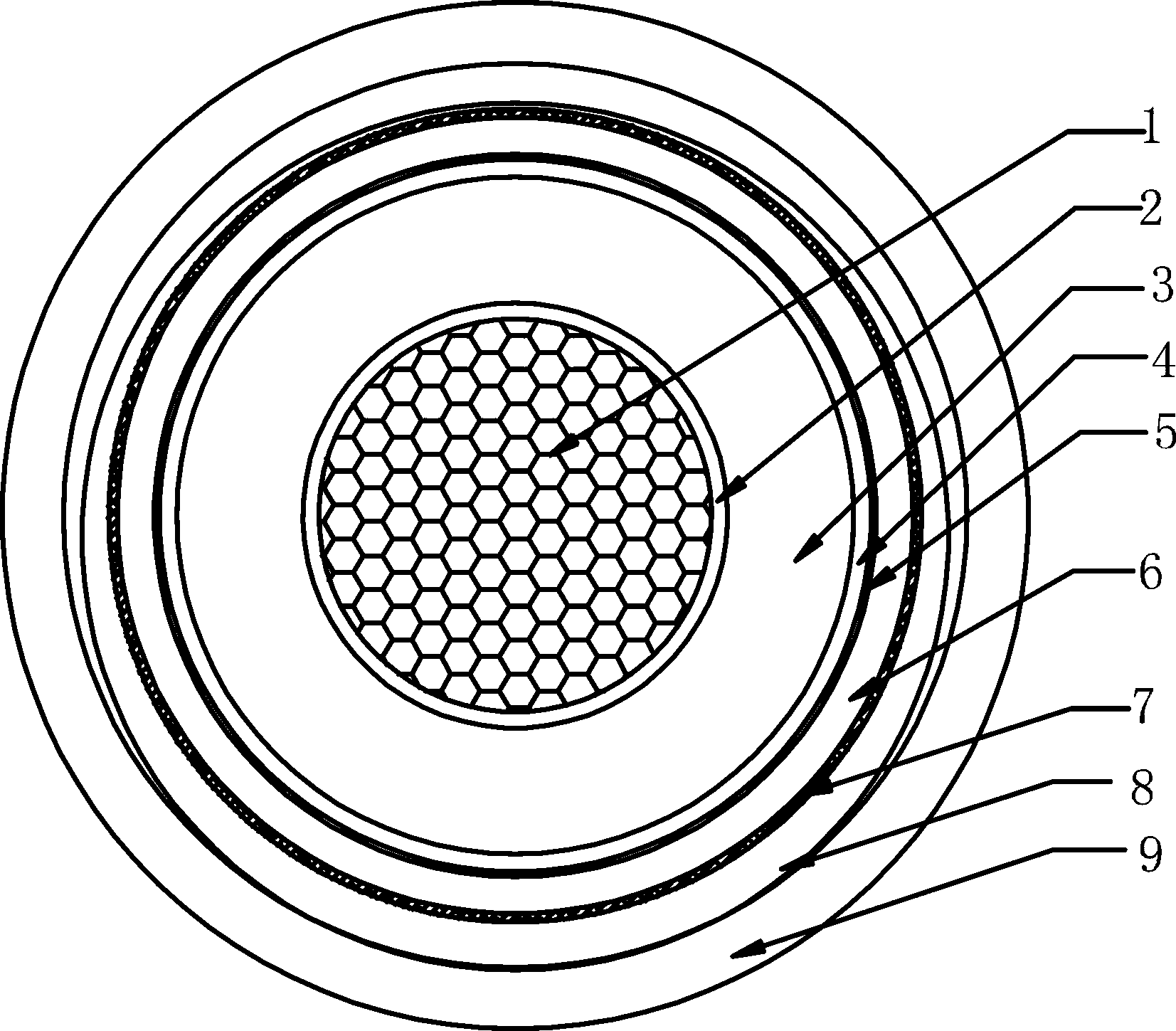

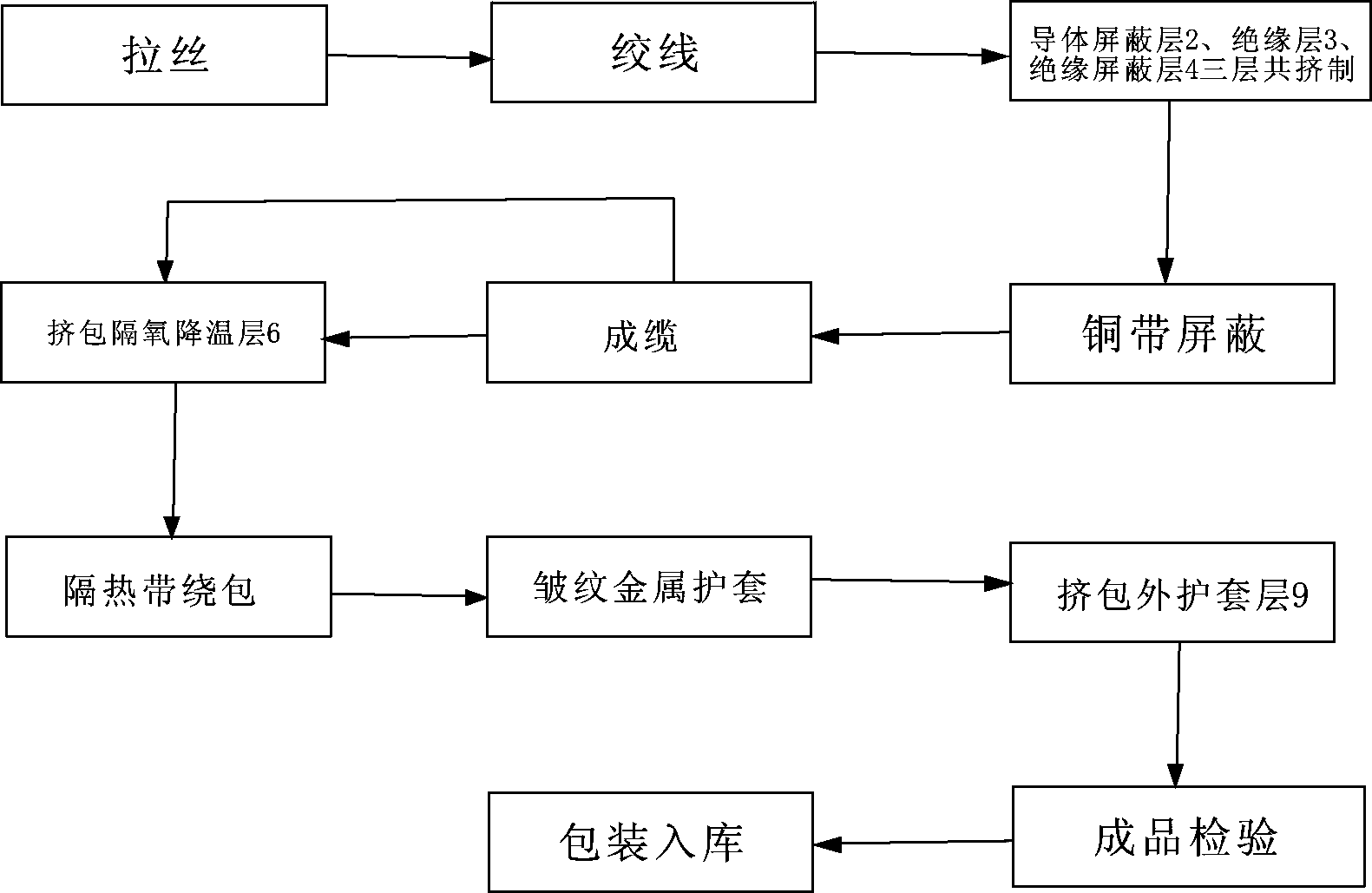

[0019] The first embodiment of the present invention is figure 1 As shown, its structure includes an insulated wire core wrapped with an insulating shielding layer 4 and a copper tape shielding layer 5, three insulated wire cores form a cable core, and the outer cable core is sequentially wrapped with an oxygen insulation and cooling layer 6, a thermal insulation layer 7, a fire-blocking layer layer 8 and non-flammable outer jacket layer 9.

[0020] The insulated wire core is composed of a copper conductor 1 , a conductor shielding layer 2 and an insulating layer 3 wrapped around the copper conductor 1 .

[0021] The insulating layer 3 is a cross-linked polyethylene insulating layer.

[0022] The insulating layer 7 is an asbestos layer, and the asbestos layer is wrapped outside the oxygen insulating and cooling layer 6 in a wrapping form.

[0023] The fire barrier layer 8 is a corrugated copper sheath.

[0024] The non-flammable outer sheath layer 9 is a low-smoke halogen-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com