A Chip-Dielectric Filled Horn Antenna Applied to Terahertz Band Phased Array

A technology of horn antenna and dielectric filling, applied in the direction of waveguide horn, antenna, radiation element structure, etc., can solve the problems of difficult formation, large size of horn antenna, and difficulty in end-fire, etc., to improve radiation efficiency, reduce size, The effect of reducing the operating wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

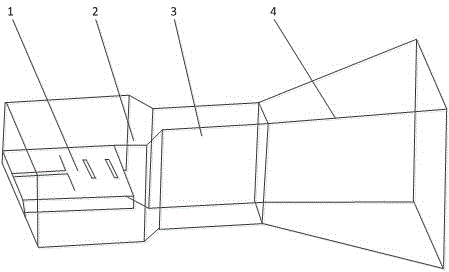

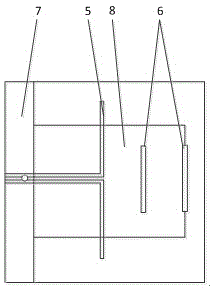

[0024] like figure 1 , figure 2 As shown, a chip-dielectric-filled horn antenna applied to a phased array in the terahertz band includes an on-chip antenna 1, a rectangular waveguide 3 connected to the on-chip antenna, and a horn antenna 4 connected to the rectangular waveguide. A transition cavity 2 is also connected between the antenna and the rectangular waveguide, and the narrow side of the rectangular waveguide is consistent with the polarization direction of the on-chip antenna, so that the rectangular waveguide is in the main mode (TE 10 mode), the transition cavity, rectangular waveguide, and horn antenna are all filled with dielectric, and the rectangular waveguide is filled with the same medium as the horn antenna. The medium is a medium with a proper dielectric constant, thereby reducing the operating wavelength of electromagnetic waves in the rectangular waveguide, thereby achieving the purpose of reducing the size of the rectangular waveguide, and reducing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com