Processes to dye and treat BCF yarn

A technology of yarn and dye composition, applied in the direction of dyeing, thin material treatment, fiber treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 (comparison)

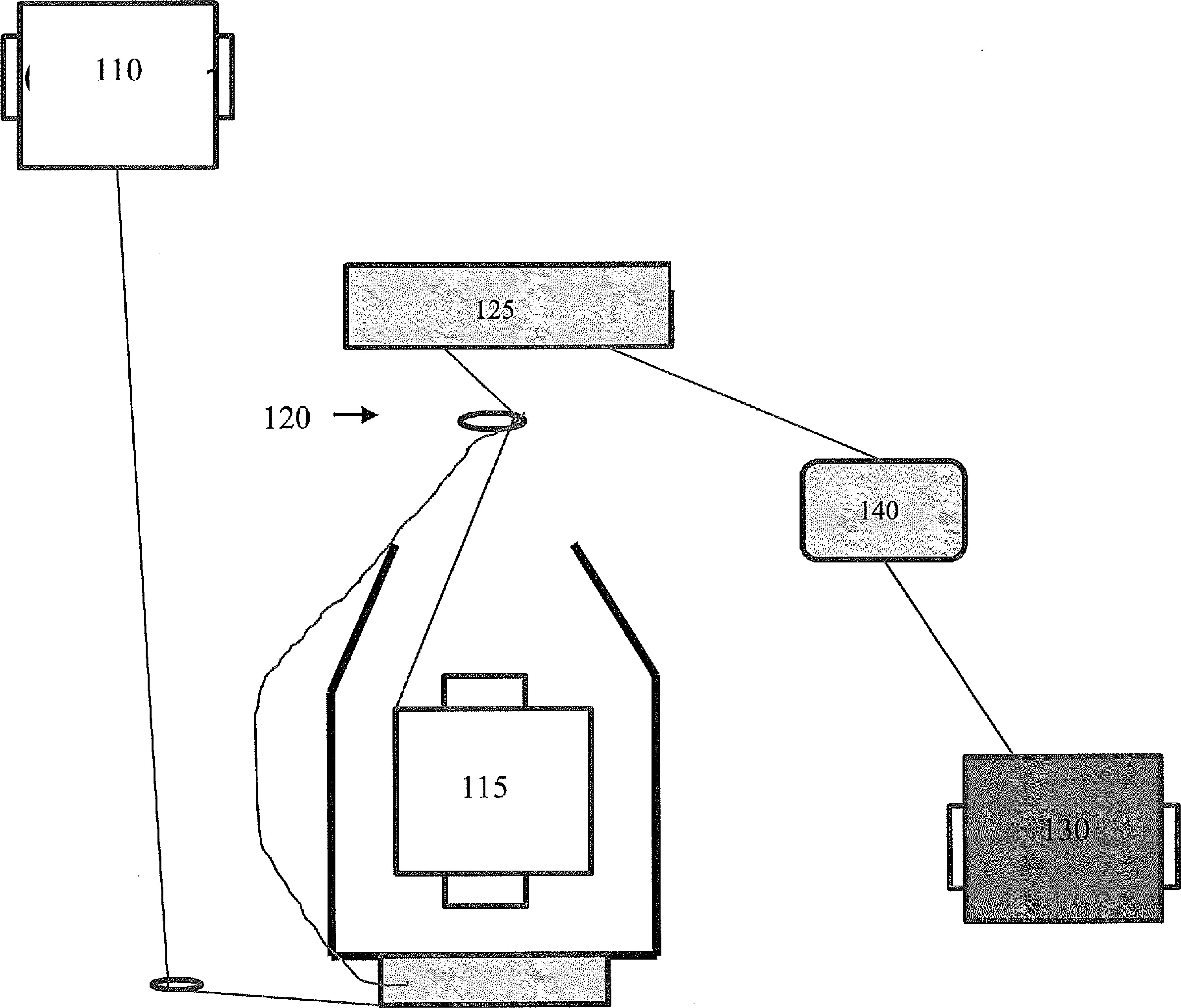

[0067] exist figure 1 Two 920 denier 8 dpf colorless nylon 6,6 BCF yarns were processed on a Volkman twister as described in to form a 5.75 tpi (twist per inch) 2-ply cabled yarn. The twisting speed was about 7000 rpm (turns per minute) and the winding speed was about 50 m / min. The cabled yarn has no color. The cabled yarn was heat set on a Superba and converted on a 1 / 8 ga tufting machine to a cut pile carpet of 22 / 32 inch pile height, 35 oz / square yard carpet and dyed on a continuous dye line to obtain Medium pie crust color. This example was carried out by dyeing the carpet using a continuous dyeing machine using state-of-the-art carpet manufacturing methods.

Embodiment 2

[0068] Embodiment 2 (the present invention)

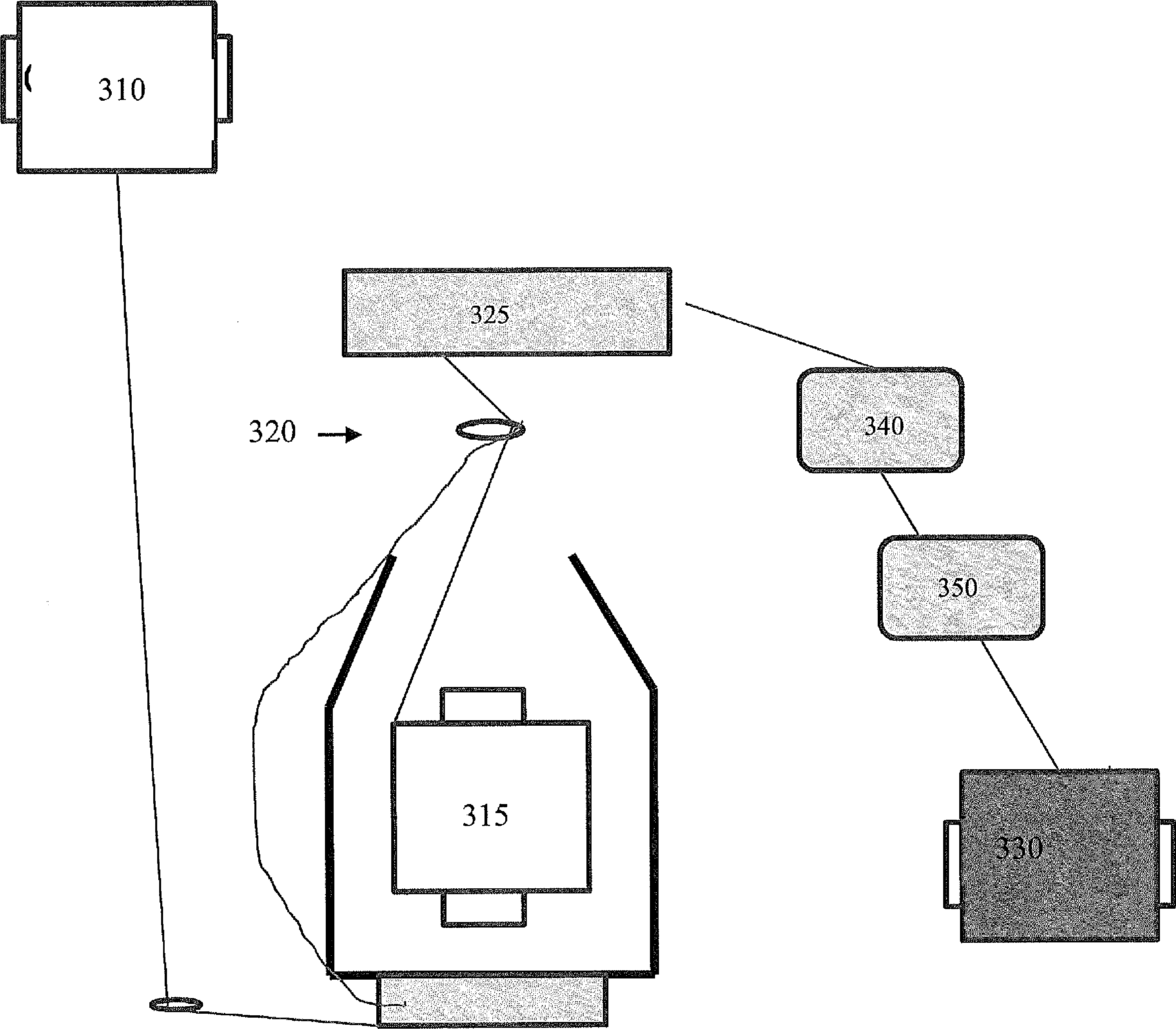

[0069] exist figure 2 Two 920 denier 8 dpf colorless nylon 6,6 BCF yarns were processed on a Volkman twister as described in to form a 5.75 tpi (twist per inch) 2-ply cabled yarn. A wicking dye applicator is inserted between the take-up roll and the winder. Acid dye mixture (Blue 4R 5.0 g / l and Orange 3G 2.0 g / l in deionized water, pH 9.47) was applied to the cabled yarn using a 0.5 inch wide by 1 inch thick cotton wick (wet wick, Perperell MA) on-line. The twisting speed was about 7000 rpm (turns per minute) and the winding speed was about 50 m / min. The cabled yarns were heat set on a Superba at 265°F and tufted on a 1 / 8 ga tufting machine to a cut pile carpet of 22 / 32 inch pile height, 35 oz / square yard of carpet. The tufted carpet has a medium shade of green (L 51.26, a-9.71, b +1.45, Minolta).

Embodiment 3

[0070] Embodiment 3 (the present invention)

[0071] exist figure 2 Two 920 denier 8 dpf colorless nylon 6,6 BCF yarns were processed on a Volkman twister as described in to form a 5.75 tpi (twist per inch) 2-ply cabled yarn. A wicking dye applicator is inserted between the take-up roll and the winder. Acid dye mixture (Orange 3G 5.712 g / l, Red 2B 2.52 g / l in deionized water, pH 6) was applied to cabled yarn using a 0.5 inch wide by 1 inch thick cotton wick (wet wick, Perperell MA) on-line. The twisting speed was about 7000 rpm (turns per minute) and the winding speed was about 50 m / min. The cabled yarns were heat set on a Superba at 265°F and tufted on a 1 / 8 ga tufting machine to a cut pile carpet of 22 / 32 inch pile height, 35 oz / square yard of carpet. This tufted rug is bright brown in color (L 39.17, a 10.48, b 18.14, Minolta). There were many dark, medium and light spots randomly distributed on the blanket, which produced an interesting salt and pepper toner mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com