A corn threshing machine

A corn threshing and chopping machine technology, which is used in threshing equipment, agricultural machinery and implements, grain processing and other directions, can solve the problems of not satisfying the integration of corn threshing and chopping, with corn cobs slag, and large damage to corn kernels. , to achieve the effect of small size, uniform broken sticks, volume and lightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

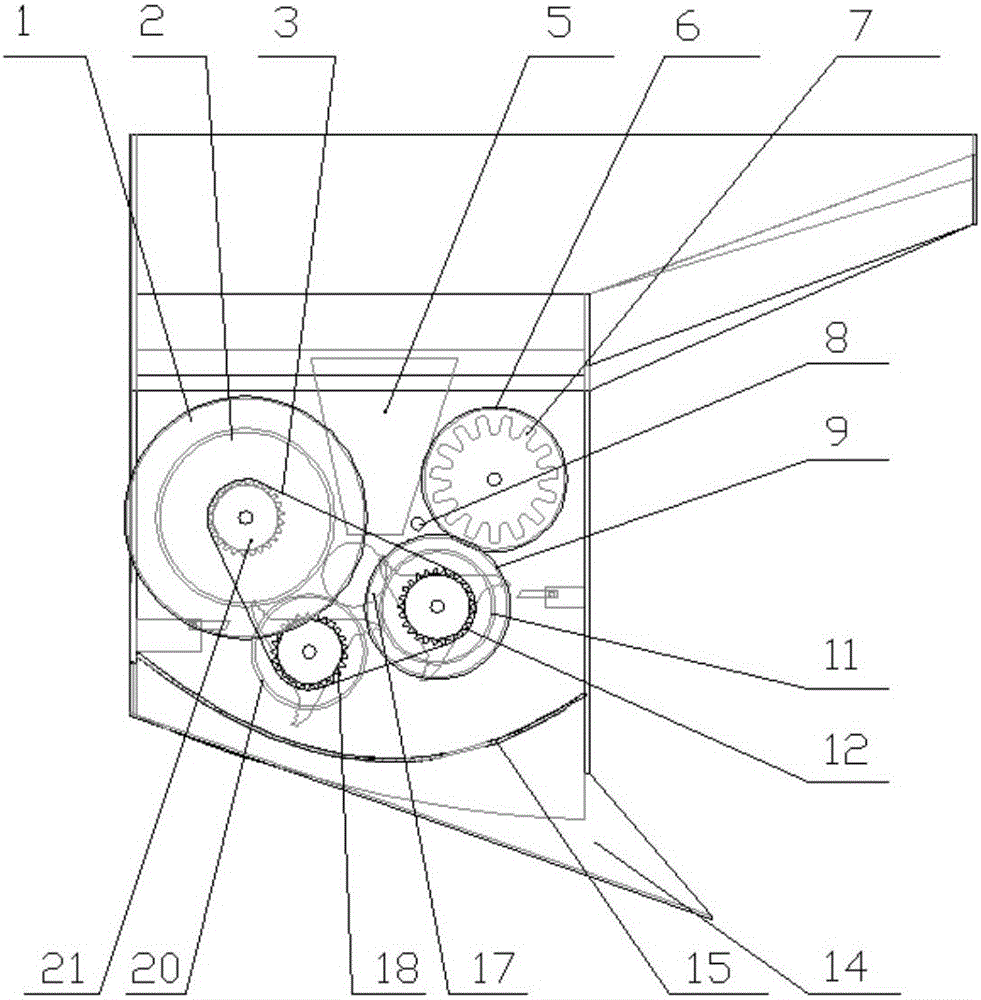

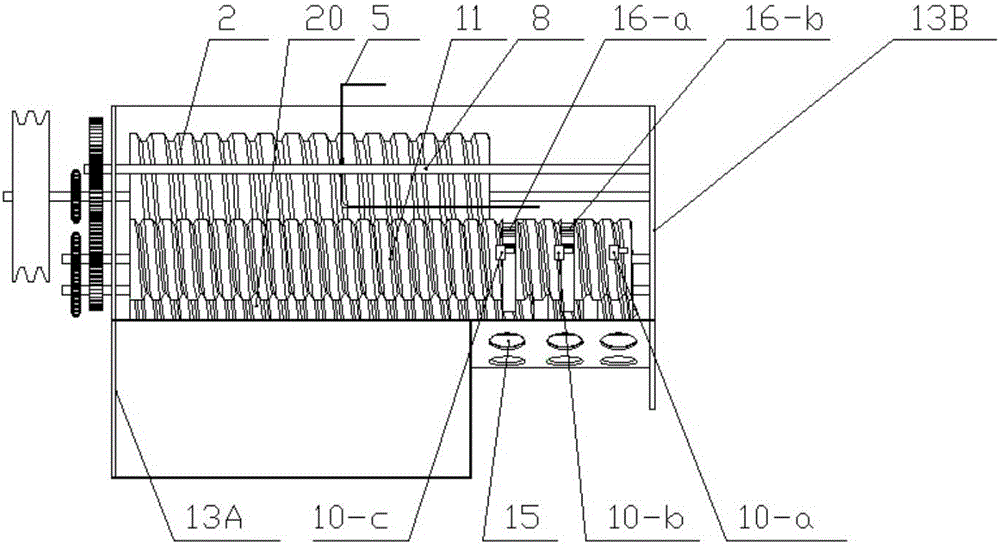

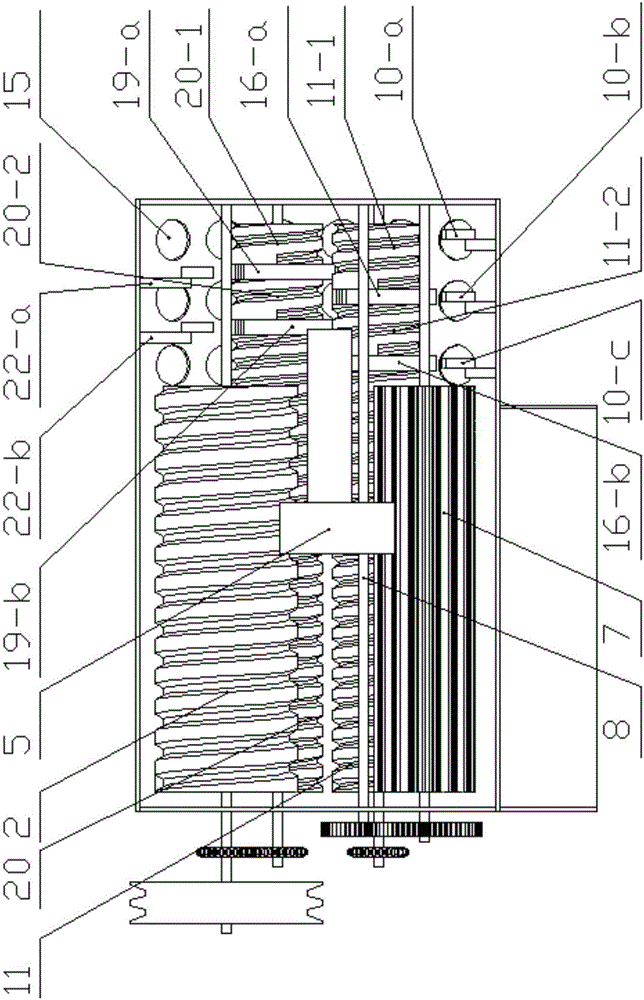

[0013] Referring to the accompanying drawings, the corn threshing broken stick part is installed in the frame under the corn threshing inlet as shown in the figure, and the straight toothed roller 7, the small helical toothed roller 11, and the small helical roller between the end plate 13A and the end plate 13B are installed. toothed roller block , small helical tooth roller block , slag discharge spiral tooth roller 20, slag discharge spiral tooth roller block , , A fixed knife , B fixed knife , C fixed knife , A fixed knife , B fixed knife , A knife , B knife , A knife , B knife A V-shaped space with a large upper part and a smaller lower part is formed between the large helical toothed roller 2 and an L-shaped baffle plate 5 under the corn threshing feed inlet. Roller bar 8 is arranged on one side in the machine, rod outlet 17 is arranged on the end plate 13B, and corn grain outlet 14 is arranged below all rollers. Belt pulley 1 is coaxial with spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com