Patents

Literature

42results about How to "No debris" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Easily-stripped film

InactiveCN101856899AImprove seal strengthImprove integrityFlexible coversWrappersComposite filmPolybutylene

The invention relates to an easily-stripped film, which is formed by extruding three layers of thin films, namely, a composite layer, an intermediate layer and a heat-seal layer. The composite layer comprises the following components in percentage by weight: 65 percent of polyethylene (Q281) and 35 percent of polyethylene (2420H); the intermediate layer comprises the following components in percentage by weight: 50 percent of polyethylene (2426H) and 50 percent of polyethylene (2420H); and the heat-seal layer comprises the following components in percentage by weight: 65 percent of polyethylene (Q281), 20 percent of polybutylene (PB-1) and 15 percent of polyethylene (SP1510). The easily-stripped film implemented by adopting the technical scheme can be compounded with biaxially stretched films such as a biaxially oriented polyester film (BOPET), a biaxially oriented nylon film (BOPA) and the like to be produced into an easily-stripped composite film so as to be produced into an easily-stripped packaging bag. In the packaging bag, the seal strength is between 5 and 10 N / 25mm; the stripped part can whiten; the stripped surface is smooth and clean; and the seal integrality is high.

Owner:美迪科(上海)包装材料有限公司

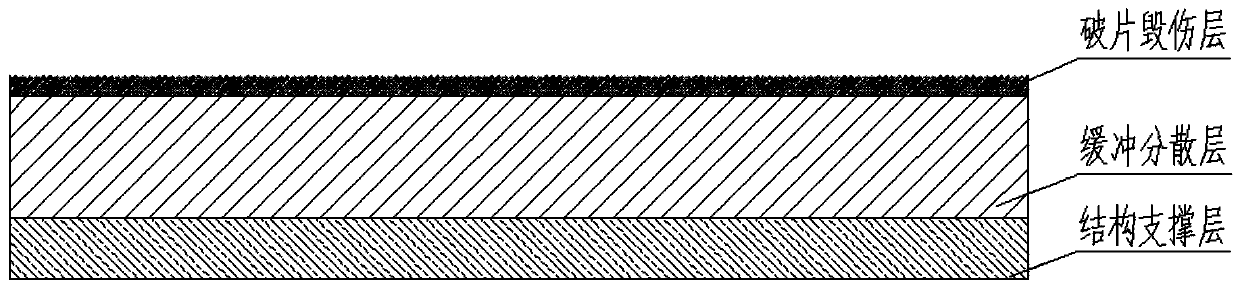

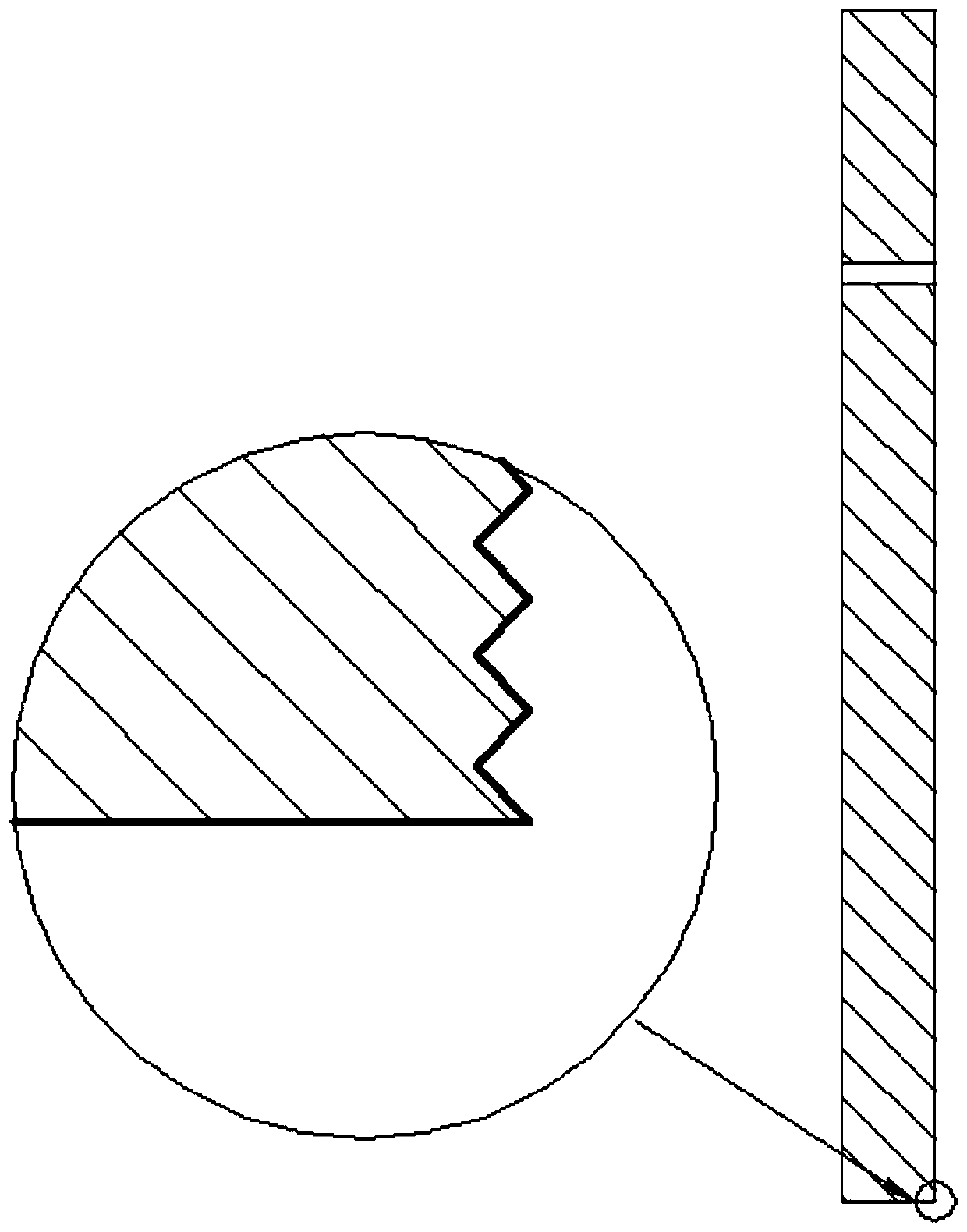

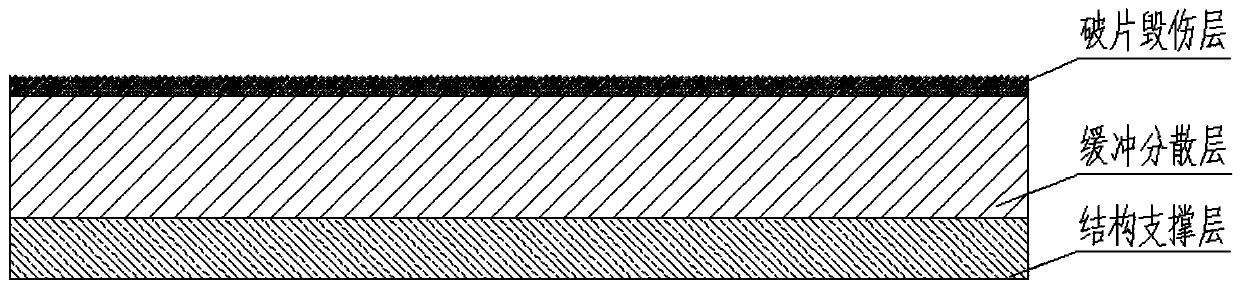

Composite explosion-proof board capable of shielding high speed broken sheets and high strength blasting impact, and manufacturing method thereof

ActiveCN110202872ASimple structureLow costLamination ancillary operationsProtective equipmentFiberGlass fiber

The invention discloses a composite explosion-proof board capable of shielding high speed broken sheets and high strength blasting impact. The composite explosion-proof board capable of shielding highspeed broken sheets and high strength blasting impact comprises a broken sheet damage layer, a buffer dispersion layer, and a structure support layer; the broken sheet damage layer is prepared from high strength constructional steel; the buffer dispersion layer is prepared from ultra high molecular polyethylene fiber; the structure support layer is composed of glass fiber and an epoxy composite material; the broken sheet damage layer, the buffer dispersion layer, and the structure support layer are laminated successively, and are bound using an epoxy adhesive. The structure is simple; the cost is low; manufacturing is convenient; shielding performance on high speed broken sheets and high strength blasting impact is excellent; and the composite explosion-proof board is an excellent explosion-proof material.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

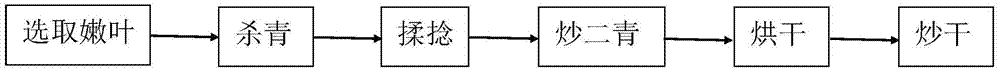

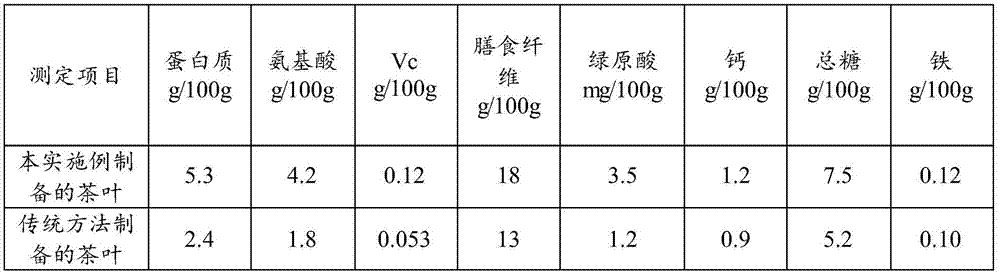

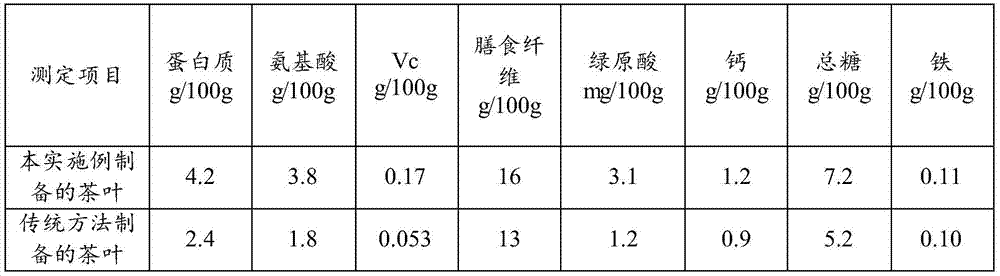

Gynura procumbens tea and preparation method thereof

InactiveCN106922894ARetain nutrientsGuaranteed health benefitsTea substituesAdditive ingredientEnzyme

The present invention relates to the scientific and technical field of tea industry and more particularly discloses gynura procumbens tea and a preparation method thereof. The preparation method of the gynura procumbens tea comprises the following steps: gynura procumbens leaves are subjected to enzyme deactivating at a condition of 120-130 DEG C for 3-5 min; the enzyme deactivated gynura procumbens leaves are taken, the taken gynura procumbens leaves are rolled, the rolled gynura procumbens leaves are pan-fired again, the pan-fired gynura procumbens leaves are dried, the dried gynura procumbens leaves are dried to be dry, and the gynura procumbens tea is obtained. The preparation method of the gynura procumbens tea can maximally preserve the nutrients in the gynura procumbens, ensures the health-care effects, and at the same time effectively removes the vegetable odor of the gynura procumbens. The prepared gynura procumbens tea is bright in tea color, free of debris, good in shaping, bright and clear after brewing, pure in mouthfeel, free of peculiar smell, and sweet in aftertaste, and has delicate fragrance of the tea.

Owner:北京万源普达医疗科技有限公司

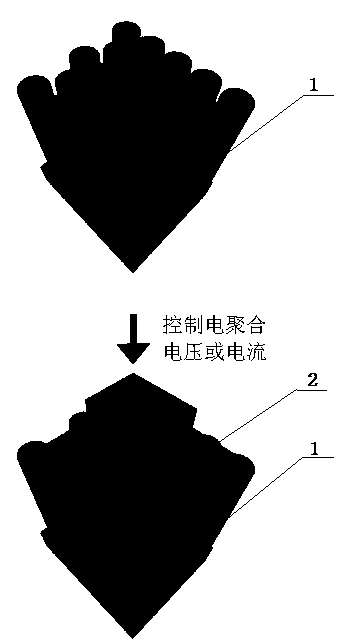

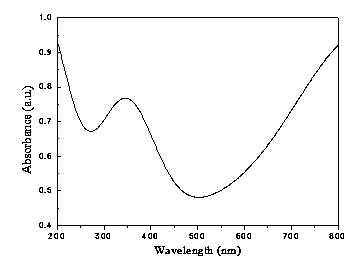

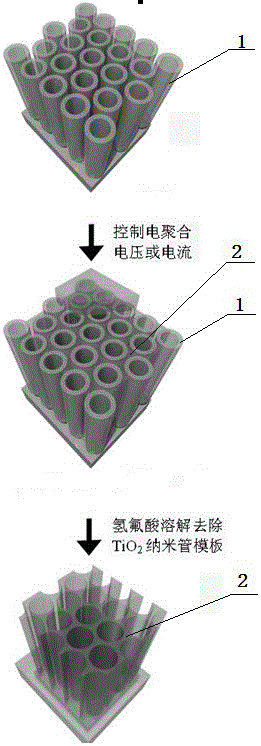

TiO2 nanotube array intertube-space filled polyethylenedioxythiophene composite material, and preparation method and application thereof

InactiveCN103361696AImprove conductivityImprove solubilitySurface reaction electrolytic coatingElectrolytic organic material coatingTio2 nanotubeSolar cell

The invention discloses a TiO2 nanotube array intertube-space filled polyethylenedioxythiophene composite material, and a preparation method and application thereof. The composite material is composed of independently separate TiO2 nanotube array intertube-space filled polyethylenedioxythiophenes. The preparation method sequentially comprises the following steps: carrying out secondary anodizing to obtain an independently separate TiO2 nanotube array; by using the independently separate TiO2 nanotube array as an anode and a platinum filament as a cathode, and carrying out constant-potential or constant-current electro-polymerization in a 0.1-5mM 3,4-ethylenedioxythiophene and 0.1-5mM sodium lauryl sulfate water solution to obtain the selective TiO2 nanotube array intertube-space filled polyethylenedioxythiophene composite material. The composite material can be used as a photoelectric electrode, and used in the fields of water-photolysis hydrogen production, environmental pollution treatment and dye-sensitized solar cells.

Owner:SICHUAN AGRI UNIV

Probiotic pressed candy and production method thereof

InactiveCN106359796ARaise the barrierAvoid damageConfectionerySweetmeatsAdditive ingredientMagnesium stearate

The invention discloses probiotic pressed candy and a production method thereof; the probiotic pressed candy is made from, by weight, 40-70 parts of starch, 10-30 parts of xylooligosaccharide, 20-40 parts of erythritol, 10-20 parts of glutamine, 5-15 parts of skim milk powder, 3-5 parts of probiotic powder, and 0.5-1.5 parts of magnesium stearate. The probiotic pressed candy is high in probiotic count and activity, and has the physiological functions of promoting intestinal digestive system functionality, maintaining gastric and intestinal mucosal health, enhancing human immunity and the like.

Owner:江苏阜丰生物科技有限公司

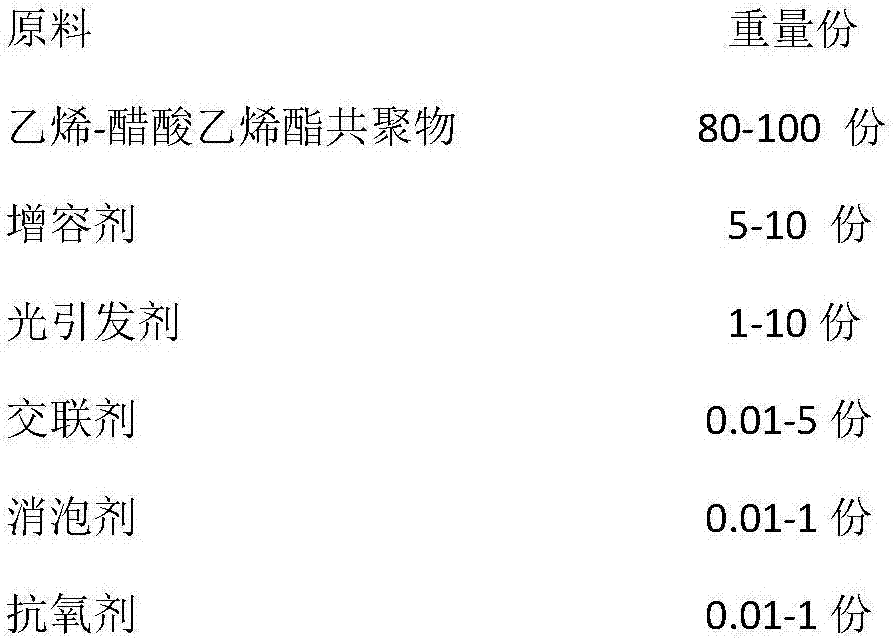

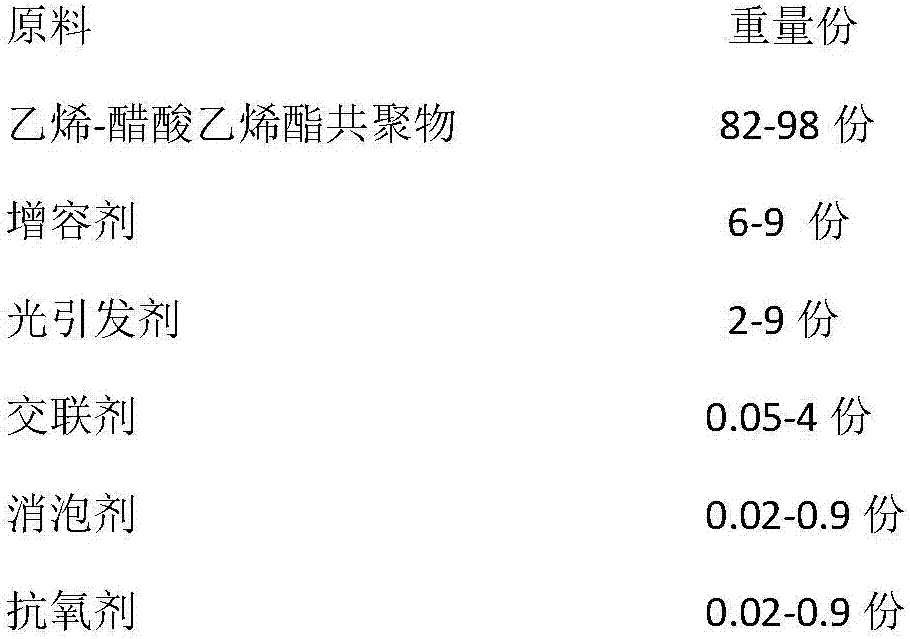

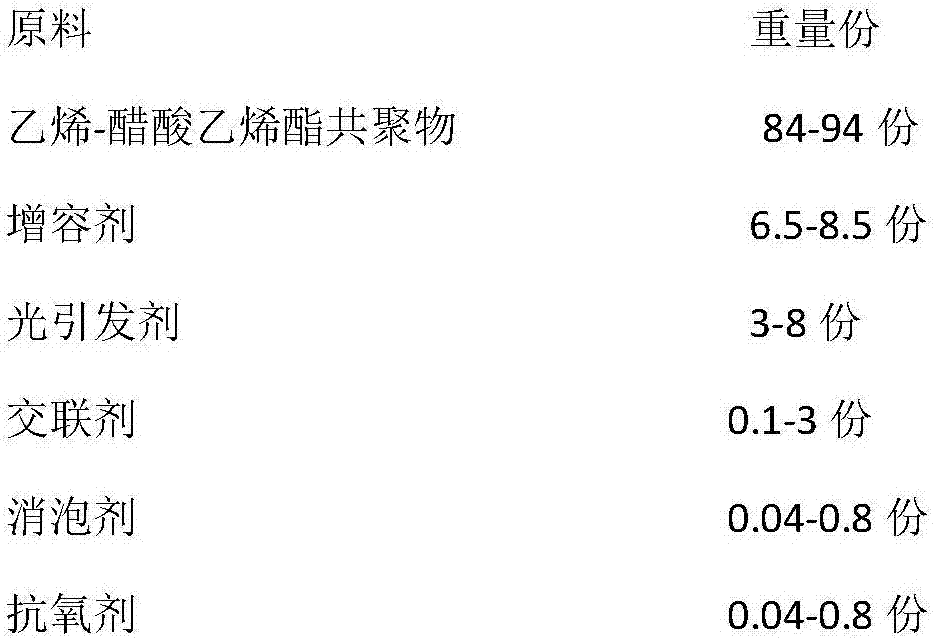

Quick crosslinked ethylene-vinyl acetate copolymer (EVA) adhesive film for double-glazed module, and preparation method of EVA adhesive film

InactiveCN107201195AIncrease productivityReduce manufacturing costNon-macromolecular adhesive additivesFilm/foil adhesivesPhotoinitiatorDefoaming Agents

The invention discloses a quick crosslinked ethylene-vinyl acetate copolymer (EVA) adhesive film for a double-glazed module, and a preparation method of the EVA adhesive film. The EVA adhesive film is prepared by mixing an EVA, a compatibilizer, a photoinitiator, a crosslinking agent, a defoaming agent and an antioxidant. The preparation method comprises the following steps: A. evenly mixing the EVA with the photoinitiator, the crosslinking agent, the compatibilizer, the defoaming agent and the antioxidant; B. evenly mixing the raw materials in a high mixing machine, and putting the mixture into an extruder for mixing, wherein the temperature of the extruder is controller to be within a range of 80-120 DEG C; C. carrying out tape casting, embossing, cooling, ultraviolet (UV)-curing and prepolymerization to form a film; carrying traction cutting, and finally winding to obtain the EVA adhesive film; D. packaging photovoltaic coated glass, a battery piece or the double-glazed module by means of the quick crosslinked EVA adhesive film for the double-glazed module. The method provided by the invention is easy to implement, simple and convenient to operate and lower in cost, reduces the processing time of the double-glazed module, and does not generate a merged piece; the defoaming agent is adopted as the raw material, so that the module is improved to be free from bubbles, and the yield of double-glazed modules is increased to be more than 99%; the preparation method is suitable for large-scale production.

Owner:JINGCHU UNIV OF TECH

Roxburgh rose black tea and preparation method thereof

ActiveCN105379869AGood for healthBeautiful appearancePre-extraction tea treatmentBiotechnologyFruit juice

The invention discloses roxburgh rose black tea which is prepared from the following raw materials in parts by weight: 20 to 30 parts of summer and autumn tea, 4 to 6 parts of roxburgh rose leaves, 0.6 to 2.4 parts of concentrated roxburgh rose juice and 0.6 to 2.4 parts of roxburgh rose dry wine. The roxburgh rose black tea provided by the invention has the following advantages: 1, fruits and leaves of roxburgh rose are effectively utilized, so that nutritional ingredients and health care effect of the roxburgh rose are effectively maintained and the prepared black tea is better in health care effect; 2, the appearance after preparation is attractive without disintegrated dreg basically; 3, in the machining process of the tea and the leaves of the roxburgh rose, juice obtained by concentrating the pulp of the roxburgh rose and roxburgh rose wine formed through deep processing and fermentation permeate into mixed leaves gradually step by step, so that the black tea is good in color and fragrance; 4, through tea-tasting by several persons, a conclusion that the black tea has a distinct honey aroma and frankincense flavor, the brewing smell is elegant and long-lasting, the color is rosy and clear, and the brewing times are obviously more than that of common black tea is obtained.

Owner:贵州华南理工生物工程有限公司

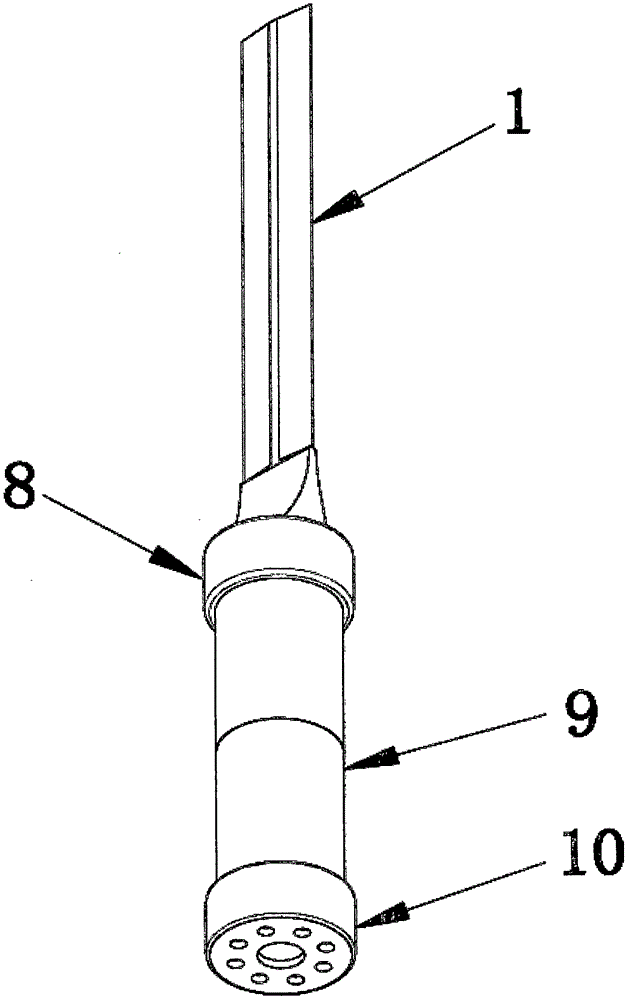

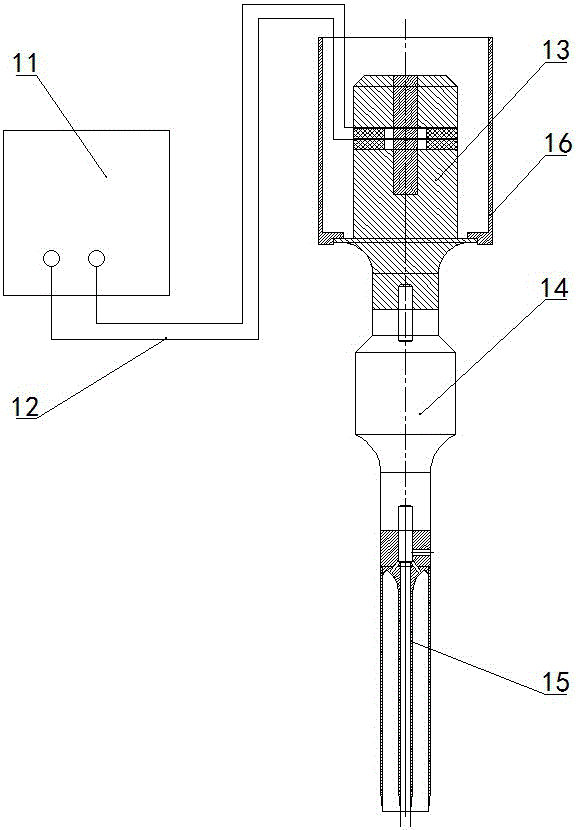

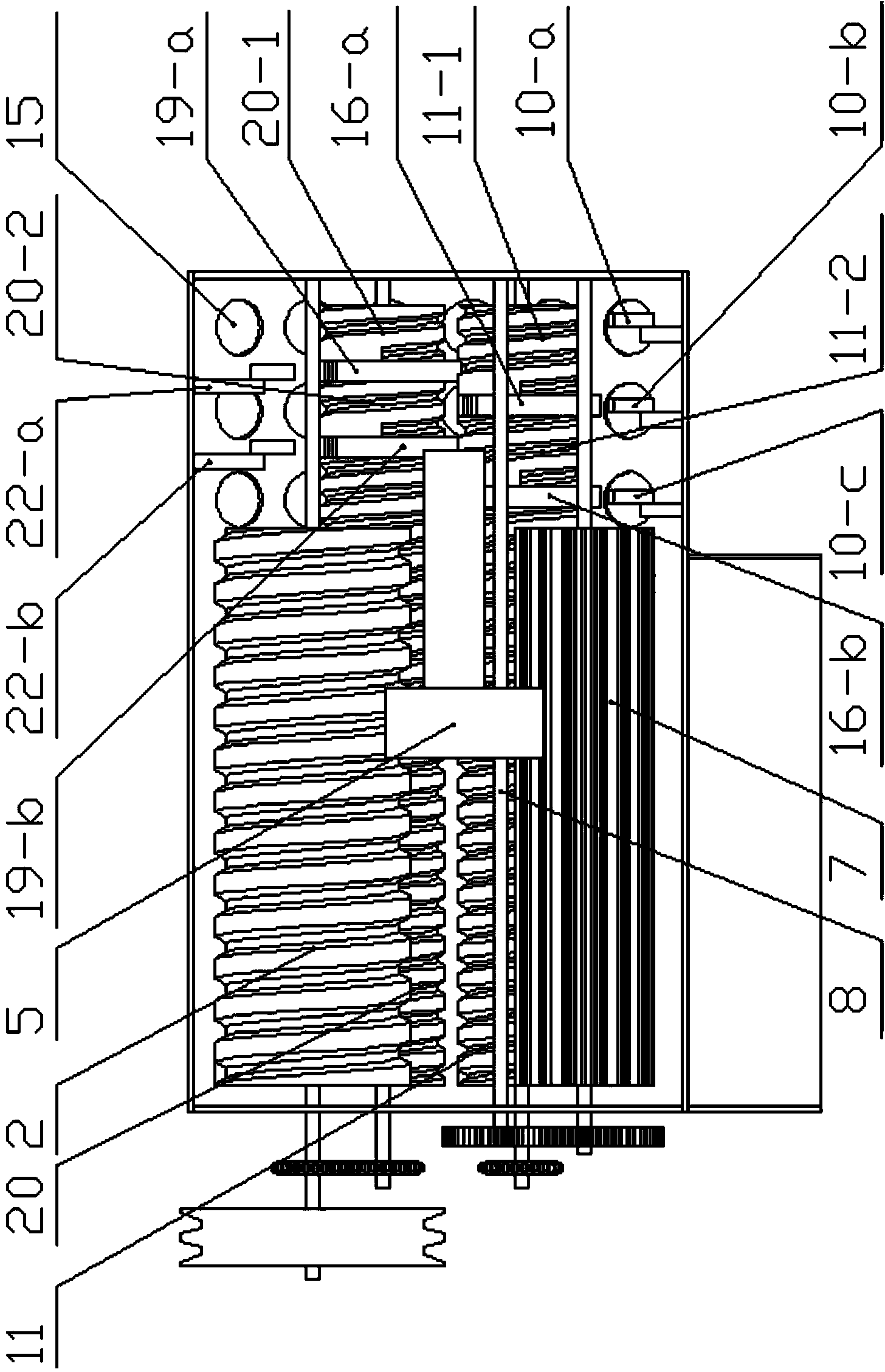

Portable ultrasonic handheld cutter

The invention discloses a portable ultrasonic handheld cutter which is mainly characterized in that a piezoelectric ceramic transducer is connected to a tool head via a 12.9-grade high-strength screw; a nylon washer A is mounted on an upper surface of a front cover zero-vibration point of the piezoelectric ceramic transducer and a nylon washer B is mounted on a lower surface thereof; a transducer middle drum and a transducer upper drum tightly press the nylon washer A and the nylon washer B by means of screw-thread fit; the piezoelectric ceramic transducer is fixed inside a transducer housing, an insulation sleeve B is mounted on the inner side of the transducer middle drum, and an insulation sleeve A is mounted on the surface of a ceramic sheet of the piezoelectric ceramic transducer, so as to prevent electrodes from being connected to metal; a transducer drum rear cover is connected to the transducer middle drum via threads; a vent hole and an aviation-plug wiring opening are formed in the transducer drum rear cover; and the aviation-plug wiring opening is connected to, via a cable, a signal cable connected to an ultrasonic drive power supply. The portable ultrasonic handheld cutter has the advantages of being small in size, light in weight, low in noise, low in energy consumption, convenient and flexible in operation, and wide in application range, and effectively reducing the cost and improving the production efficiency.

Owner:邯郸市海拓机械科技有限公司

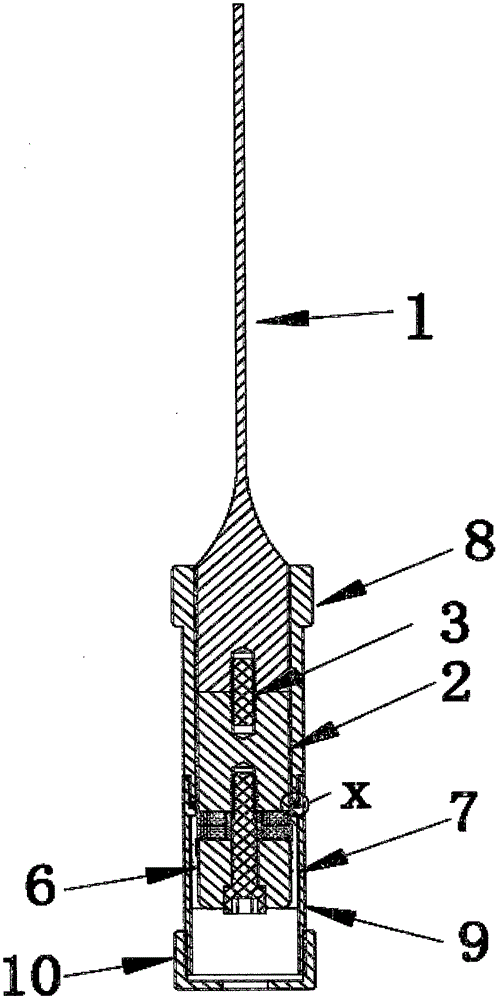

Portable ultrasonic cutter

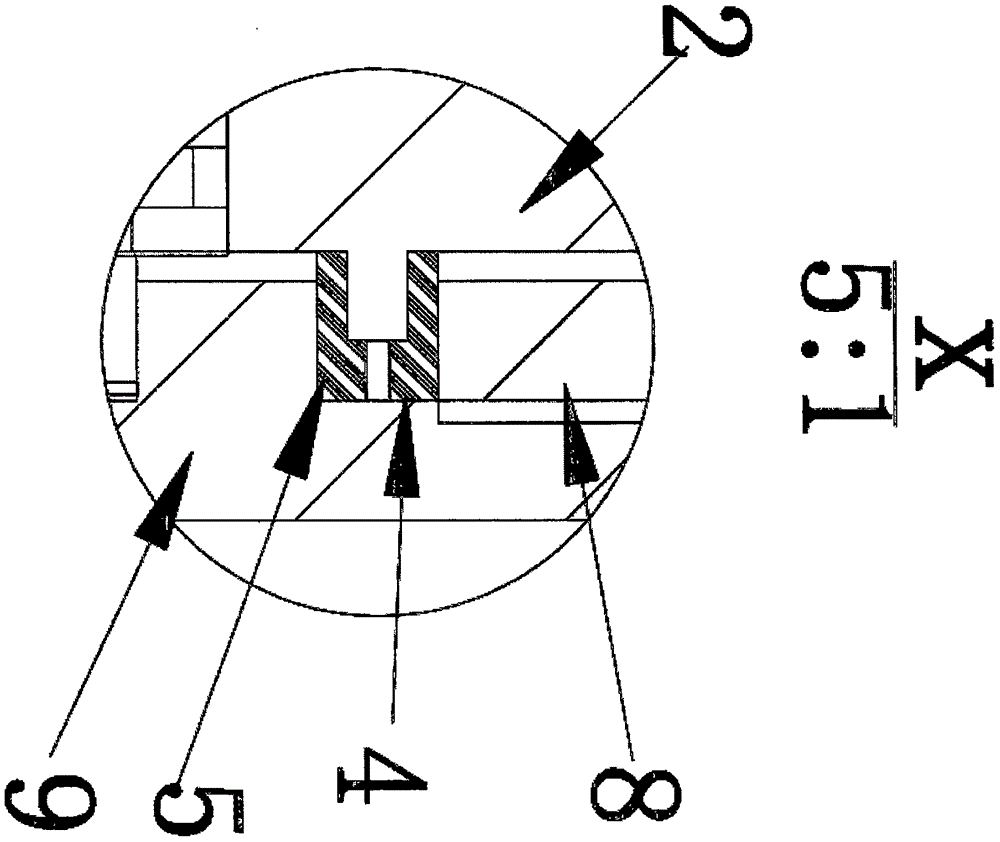

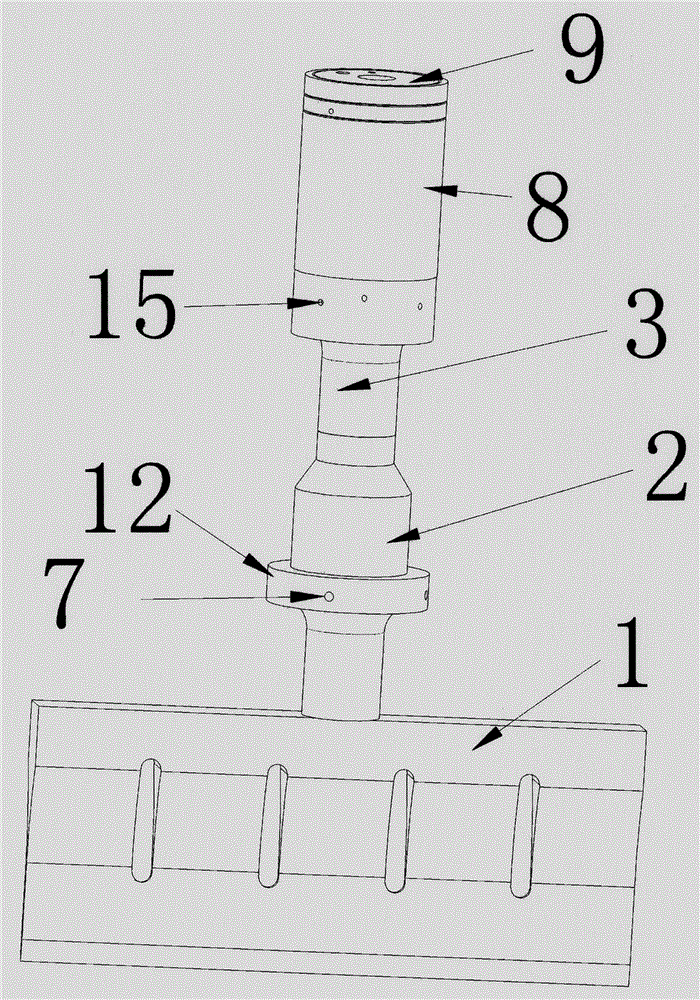

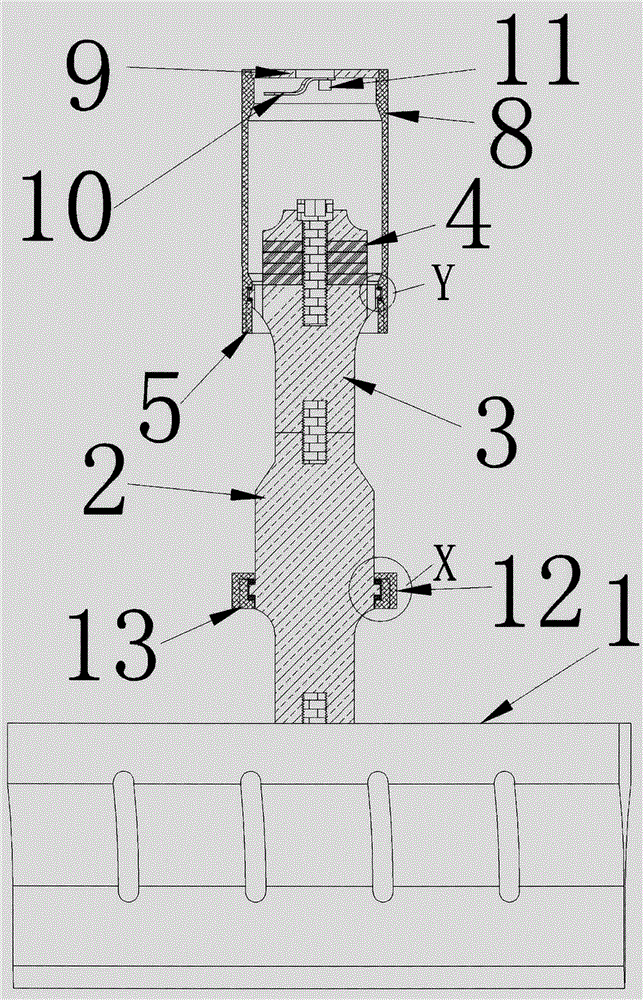

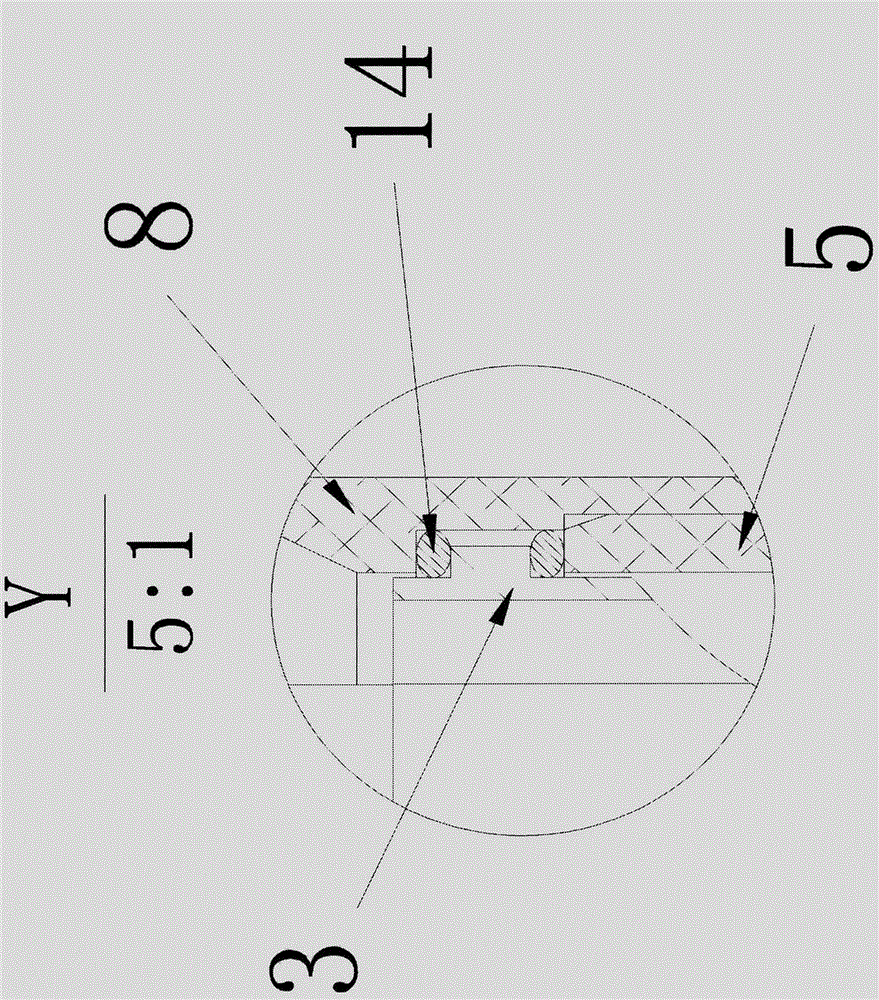

ActiveCN105235000ASolve the shatterSolve the cause of the edge collapseMetal working apparatusInterference fitAviation

The invention discloses a portable ultrasonic cutter. The portable ultrasonic cutter is mainly characterized in that a piezoelectric ceramic transducer is connected with a quarter-wavelength amplitude transformer through a high-strength screw; the big end of a half-wavelength amplitude transformer is connected with the other end of the quarter-wavelength amplitude transformer, and the small end of the half-wavelength amplitude transformer is connected with a tool head; O-shaped rings A are arranged above and below a zero vibration point of the half-wavelength amplitude transformer and clamped by means of an upper fastening ring and a lower fastening ring through interference fit, and positioning pins A are arranged in opposite positions of the zero vibration point of the half-wavelength amplitude transformer; O-shaped rings B are arranged above and below a zero vibration point of the quarter-wavelength amplitude transformer, the piezoelectric ceramic transducer is fixed in a transducer shell through compression rings, and positioning pins B are arranged in opposite positions of the zero vibration point of the quarter-wavelength amplitude transformer; a ground wire inlet is formed in the outer surface of the rear end of the transducer shell, and a rear cover which is in interference fit with the rear end of the transducer shell is installed at the rear end of the transducer shell; a wind shield is fixed to the rear cover, and the rear cover is provided with an air inlet and an aviation plug wiring port; an air outlet is formed in the quarter-wavelength amplitude transformer. The portable ultrasonic cutter has the advantages that the size of an execution mechanism is small, energy consumption is low, the application range is wide, cost can be effectively reduced, and production efficiency is improved.

Owner:邯郸市海拓机械科技有限公司

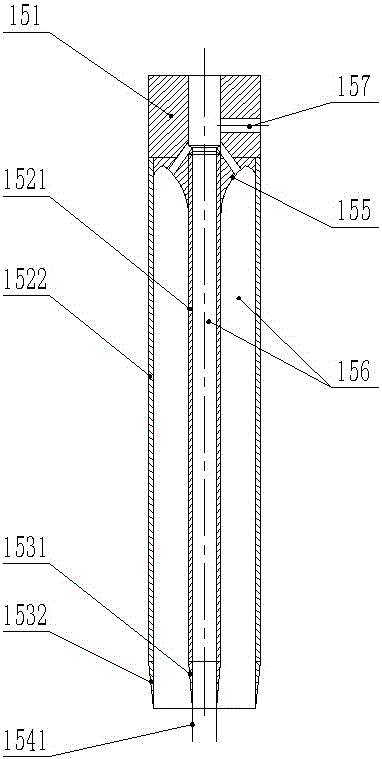

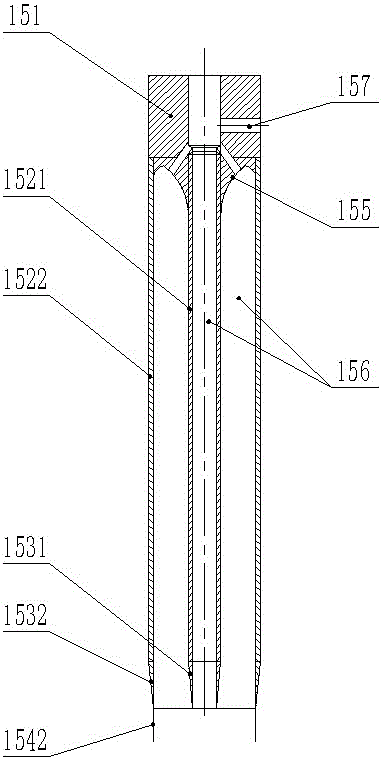

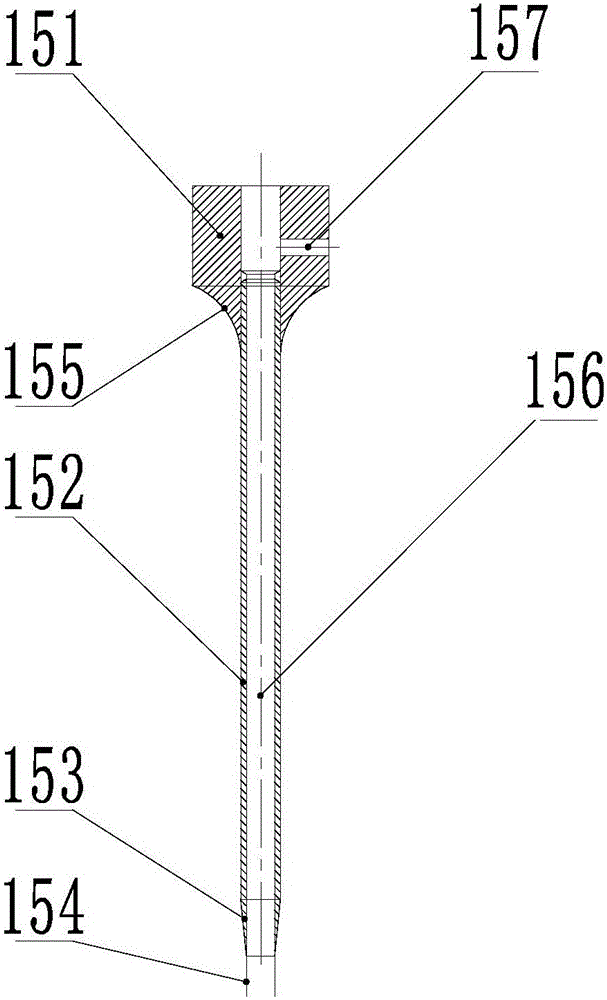

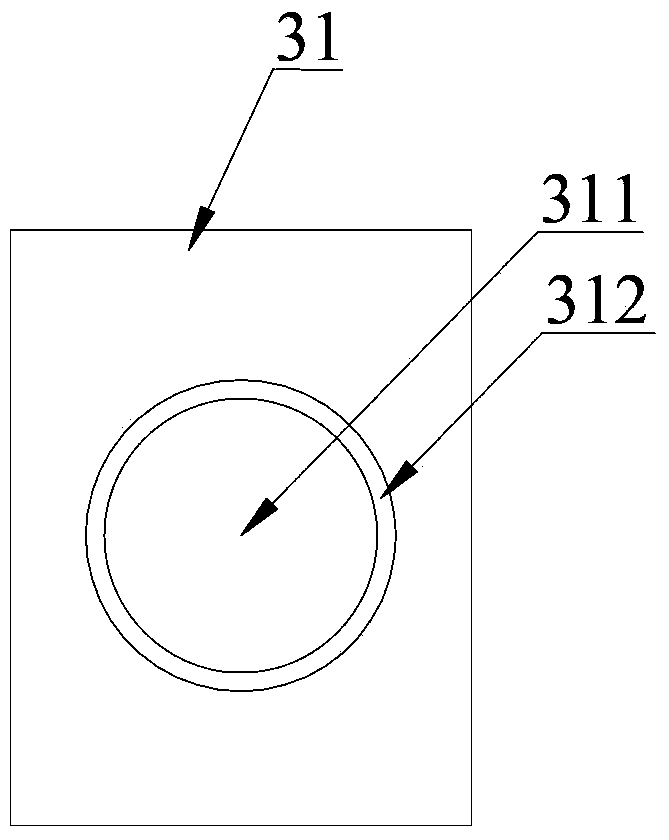

High-frequency vibratory sponge bar taking device and application

InactiveCN105666575AProcessing is of great significanceHigh precision of aperture sizeMetal working apparatusHigh frequency vibrationBiomedical engineering

The invention specifically relates to a high-frequency vibrating sponge strip-taking device and its application, which is mainly used for processing the elastic layer on the transfer roller in a printing copier. The high-frequency vibrating sponge strip-taking device includes an ultrasonic generator, an ultrasonic transducer connected to the ultrasonic generator through wires, at least one level of horn connected to the ultrasonic transducer and connected to the transducer A tubular cutter connected to the horn, the tubular cutter is threadedly connected to the connected horn, and the tubular cutter includes a connecting head connected to the horn, a tube body containing a cavity, and a cutting edge. One end of the pipe body is threadedly connected to the connector, the other end is provided with the cutting edge, and a circular arc transition structure is provided at the joint between the pipe body and the connector. The technical solution provided by the invention can easily take strips from the sponge by means of high-frequency vibration, the strip taking process is stable, the pore size precision is high, the surface of the hole wall is smooth and free of damage, the product qualification rate is greatly improved, and the production efficiency is obviously improved.

Owner:SUZHOU UNIV OF SCI & TECH

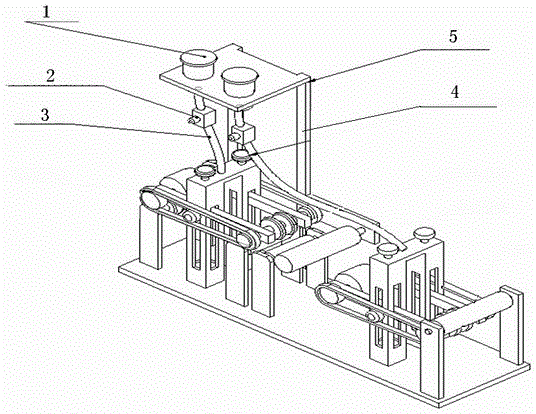

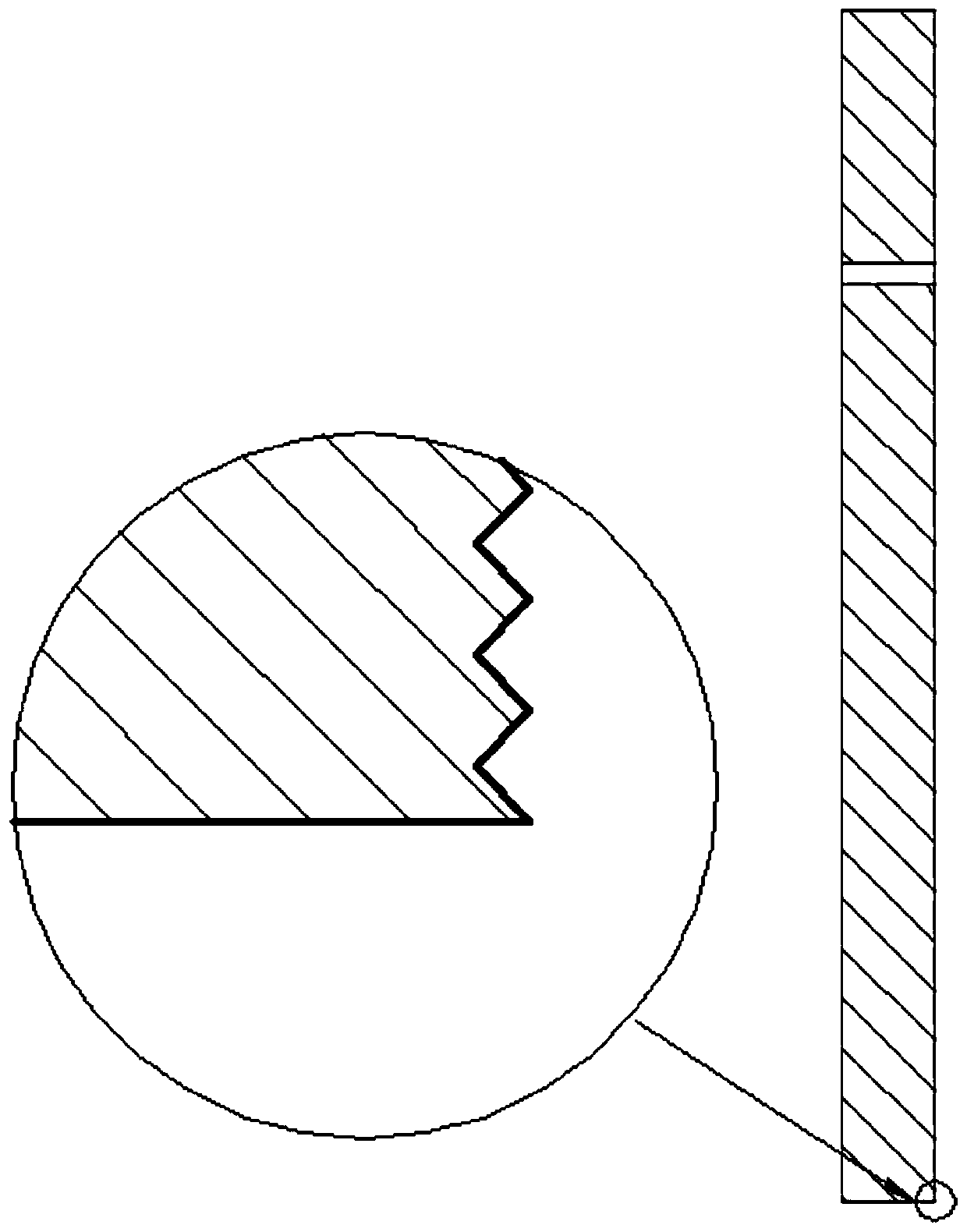

Simple grinding wheel lubricating and cooling device and beveling machine

InactiveCN105014542ASimple structureEasy to implementEdge grinding machinesGrinding/polishing safety devicesMetal stripsGrinding wheel

The invention relates to a simple grinding wheel lubricating and cooling device and a beveling machine with the same. The simple grinding wheel lubricating and cooling device mainly comprises cooling liquid cups, cooling liquid pipes and flow control switches. The cooling liquid cups are fixedly connected with the cooling liquid pipes. The wall of each cooling liquid pipe is connected with one flow control switch. The lubricating and cooling device can be installed beside the beveling machine. When the lubricating and cooling device is installed on the grinding wheel beveling machine, the tail ends of the cooling liquid pipes are fixed to the positions above a feeding belt of the beveling machine. The lubricating and cooling device is simple in structure and convenient to operate. When applied to beveling machines, the lubricating and cooling device can be flexibly installed and matched with beveling machines of various models. Through the flow control switches, cooling liquid is adjustably and evenly dripped, so that it is guaranteed that ground metal strip edges are smooth, clean, free of chippings, not sticky and free of high-temperature burns.

Owner:WUXI BAISHIJIE METAL PROD TECH

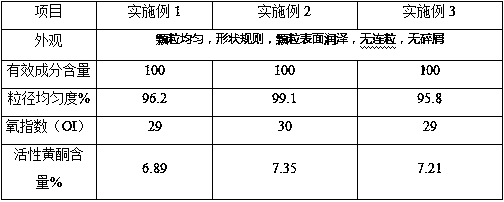

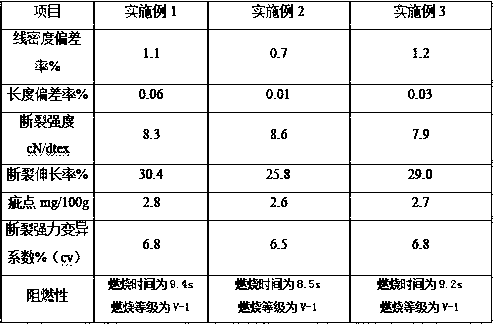

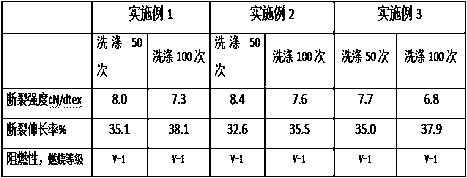

Plant-derived polypropylene master batch and preparation method thereof

InactiveCN109503946AUniform particlesRegular shapeFlame-proof filament manufactureMonocomponent polyolefin artificial filamentBreaking strengthCombustion

The invention provides a plant-derived polypropylene master batch. The plant-derived polypropylene master batch is prepared by mixing and melting polypropylene master batch and modified honeysuckle flower powder according to a mass ratio of 85:15. The invention also provides a preparation method of cellulose fiber. The prepared plant-derived polypropylene master batch has the advantages that the shape is regular, the connecting of particles is avoided, the crushed chips are avoided, the uniformity of particle size is 95.8 to 99.1%, and the OI (oxygen index) is 29 to 30. The prepared cellulosefiber has the advantages that the deviation rate of linear density is 0.7 to 1.2%, the deviation rate of length is 0.01 to 0.06%, the break strength is 7.9 to 8.3cN / dtex, the elongation rate at breakis 25.8 to 30.4%, the defect is 2.7 to 2.8mg / 100g, the combustion time of flame-retardant property is 9.4 to 8.5s, and the combustion class is V-1; after washing for multiple times, the flame-retardant effect is lasting and stable.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Dried peach fruit production method

InactiveCN104770549APrevent browningBright and clearConfectionerySweetmeatsDried peachAqueous sodium hydroxide

The present invention discloses a dried peach fruit production method which includes choosing well-ripen and freestone variety of fresh peaches, and washing and cleaning the peaches, and is characterized by the following steps: treating the washed and cleaned fresh peaches in boiled sodium hydroxide solution for 25-40 seconds, draining, rubbing, washing and peeling the soaked peaches, putting the peeled peaches into a color protecting liquid which is composed of D-sodium isoascorbate, citric acid and water, removing the fruit kernels, slicing the denucleated peaches into peach slices, blanching and scalding the peach slices in boiling water for 3 to 5 minutes, picking up the boiled peach slices to conduct draining and drying, stratifiedly adding powdered glucose to conduct sugar-soaking for 10-12 hours, spreading the sugar-soaked peach slices into a single layer at 60-70 DEG C to conduct drying for 10-12 hours, and placing the dried peach slices in an enclosed storage compartment for 12-36 hours, thereby preparing the finished products of the dried peach fruits. The dried peach fruit production method has a simple production process and is easy to operate, the technology is easy for promotion, the products are nutritious and have excellent sense and quality, and the production method can alleviate the fresh fruit storage and sale pressures for the majority of orchard workers, can also greatly enhance the added value of products, and has a strong practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

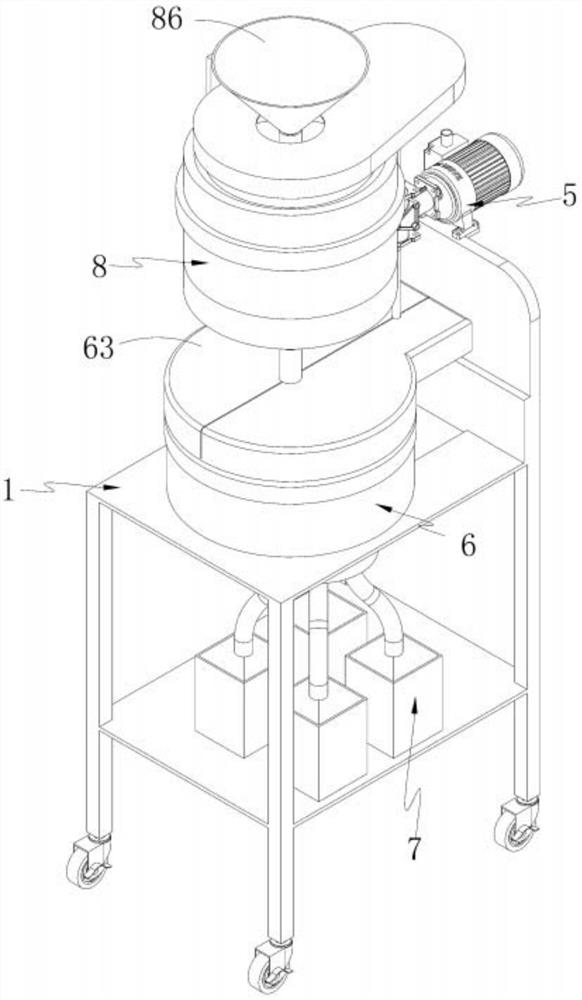

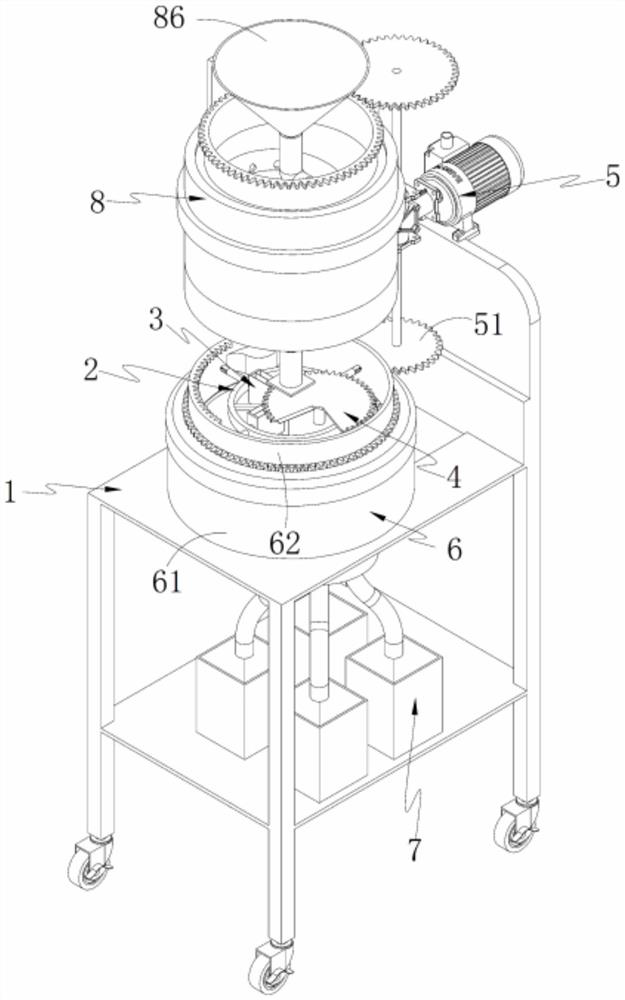

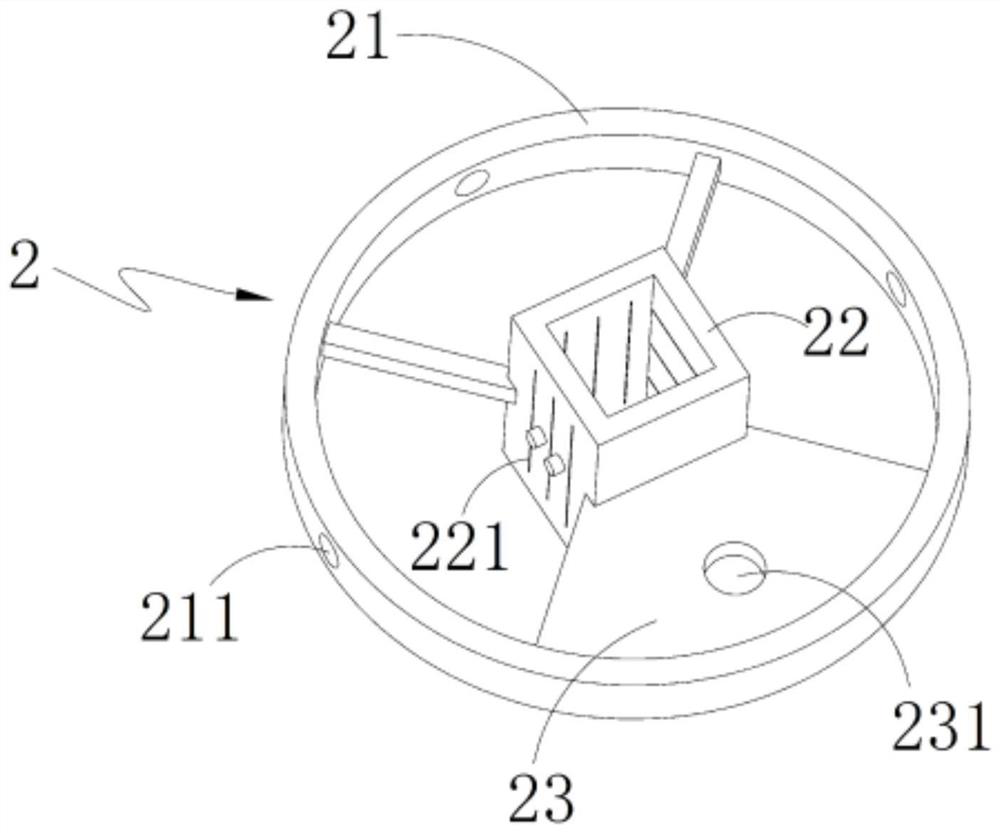

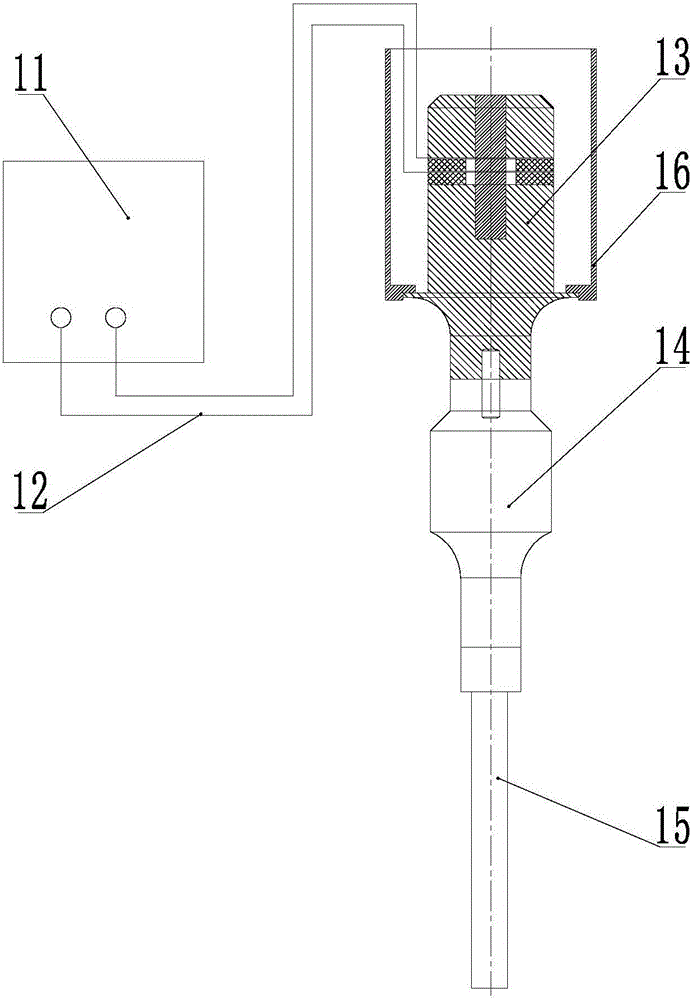

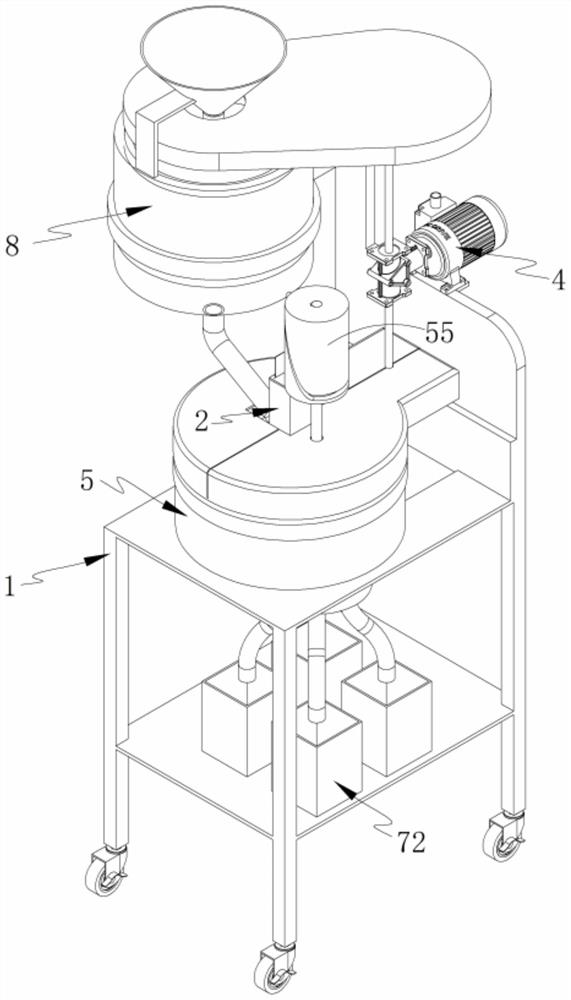

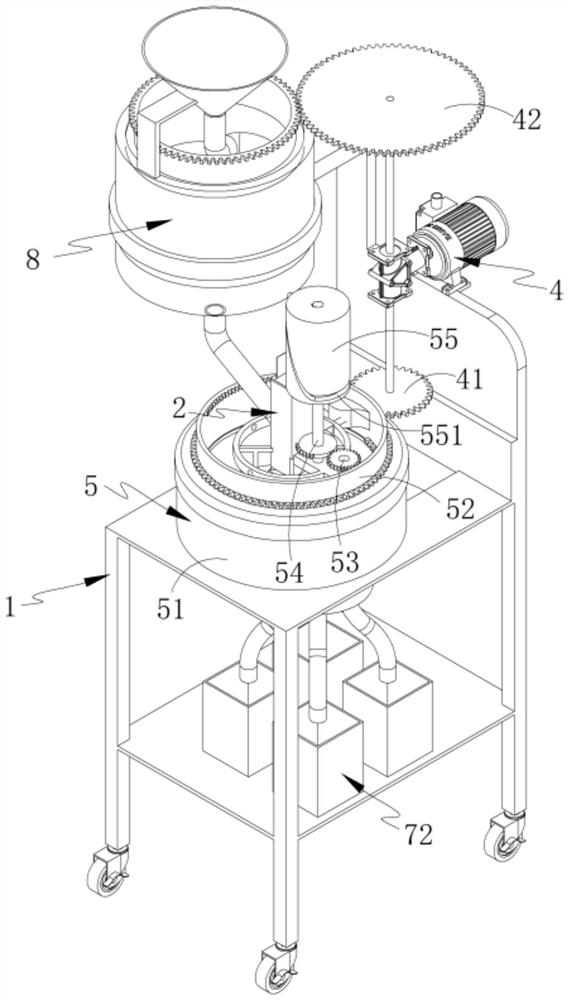

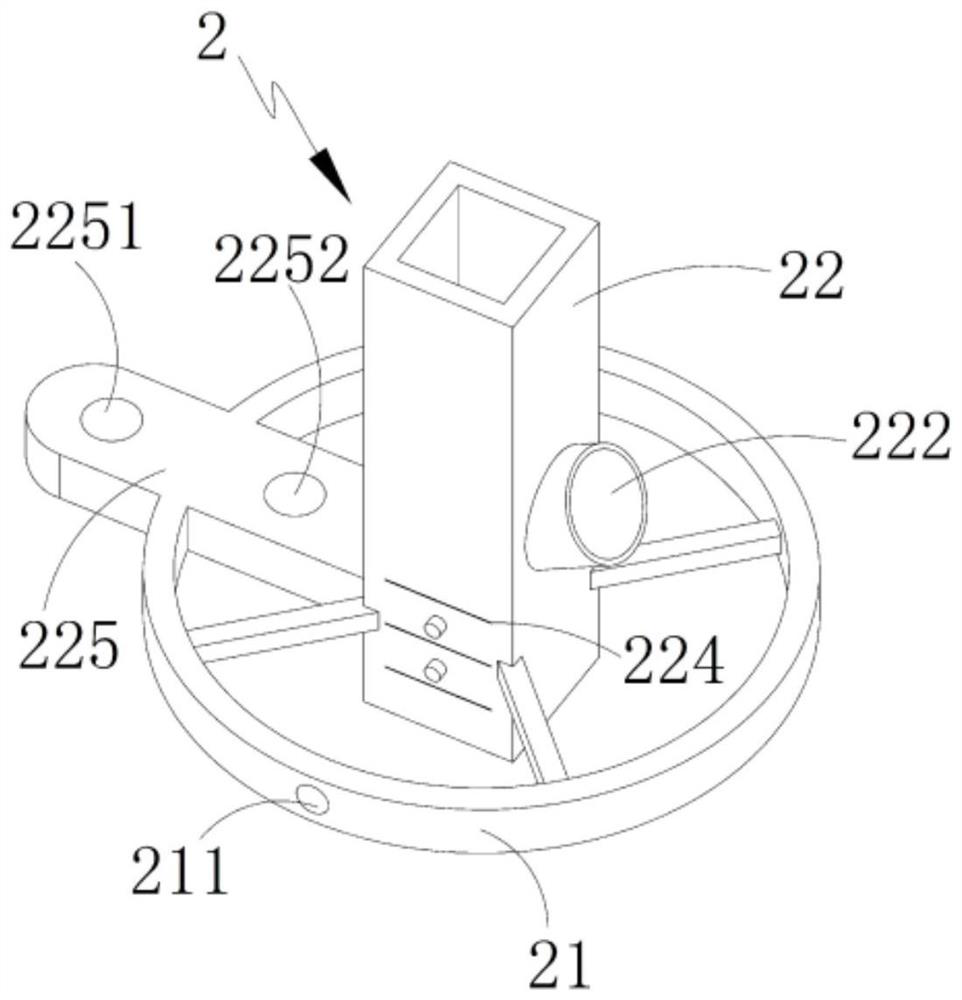

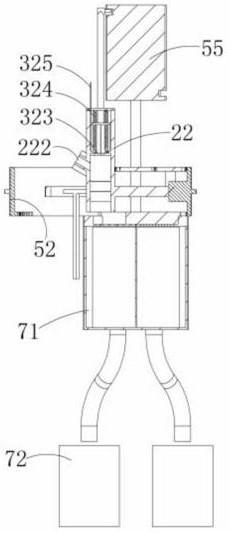

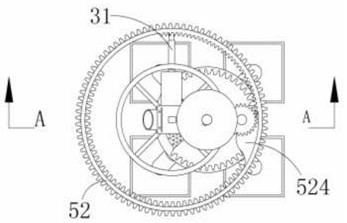

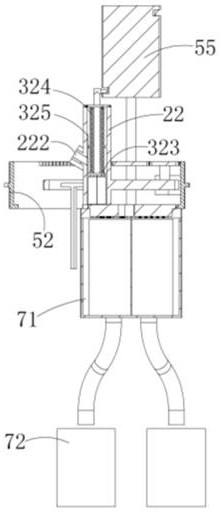

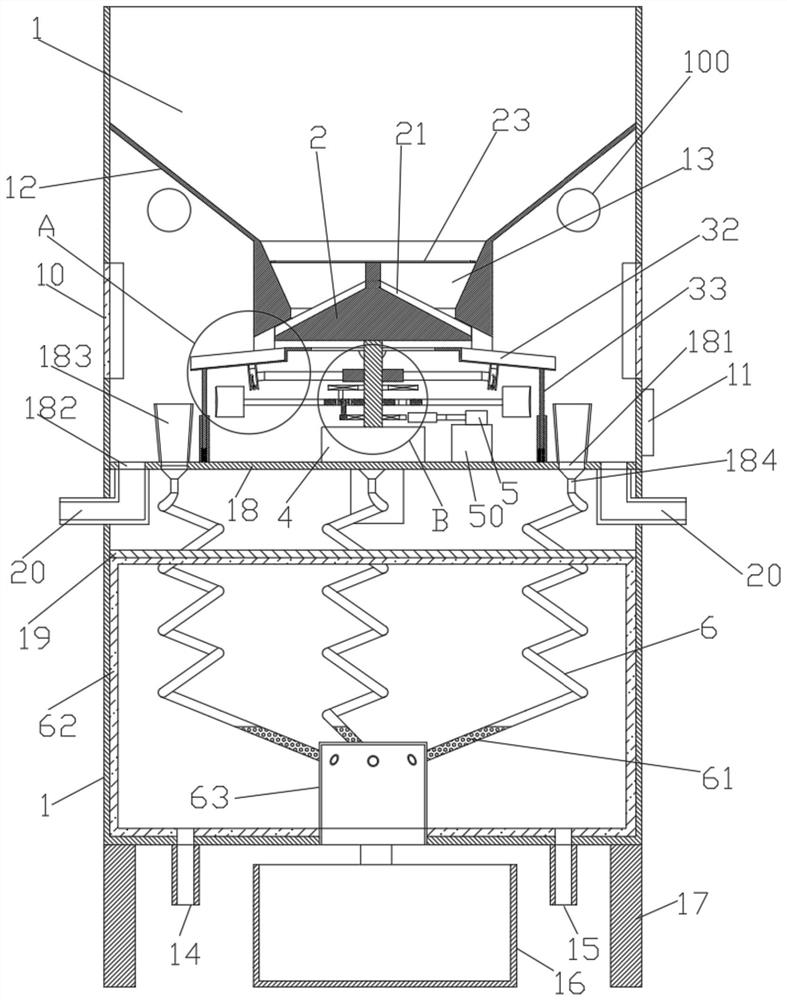

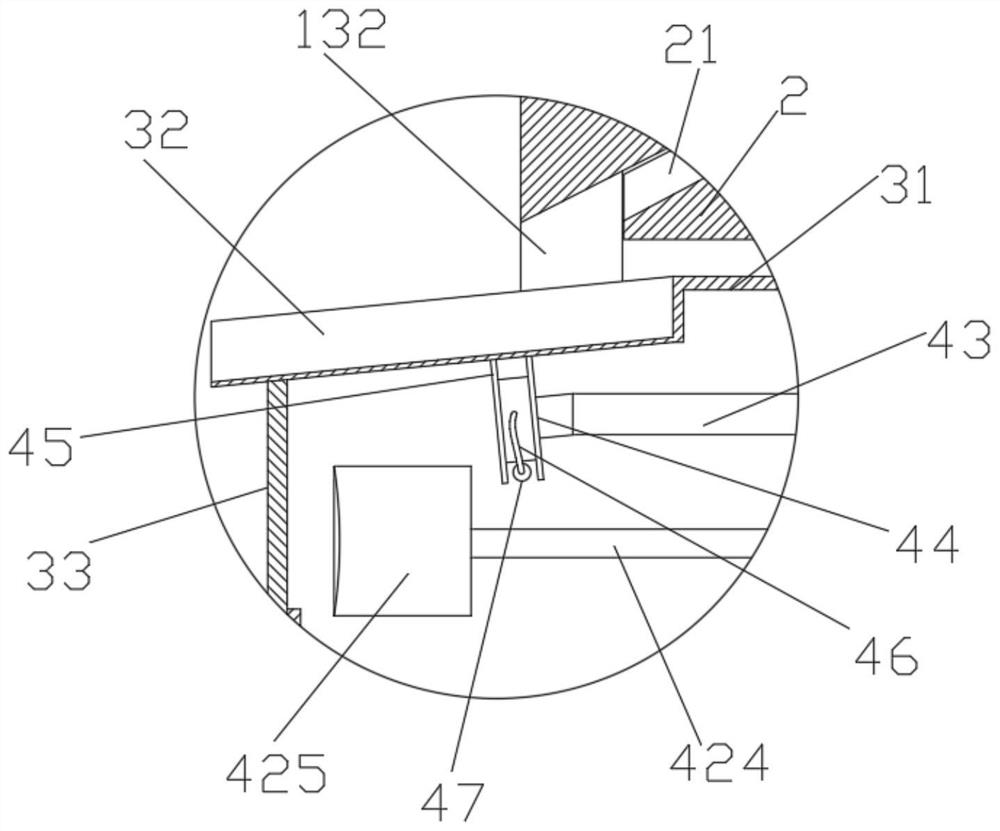

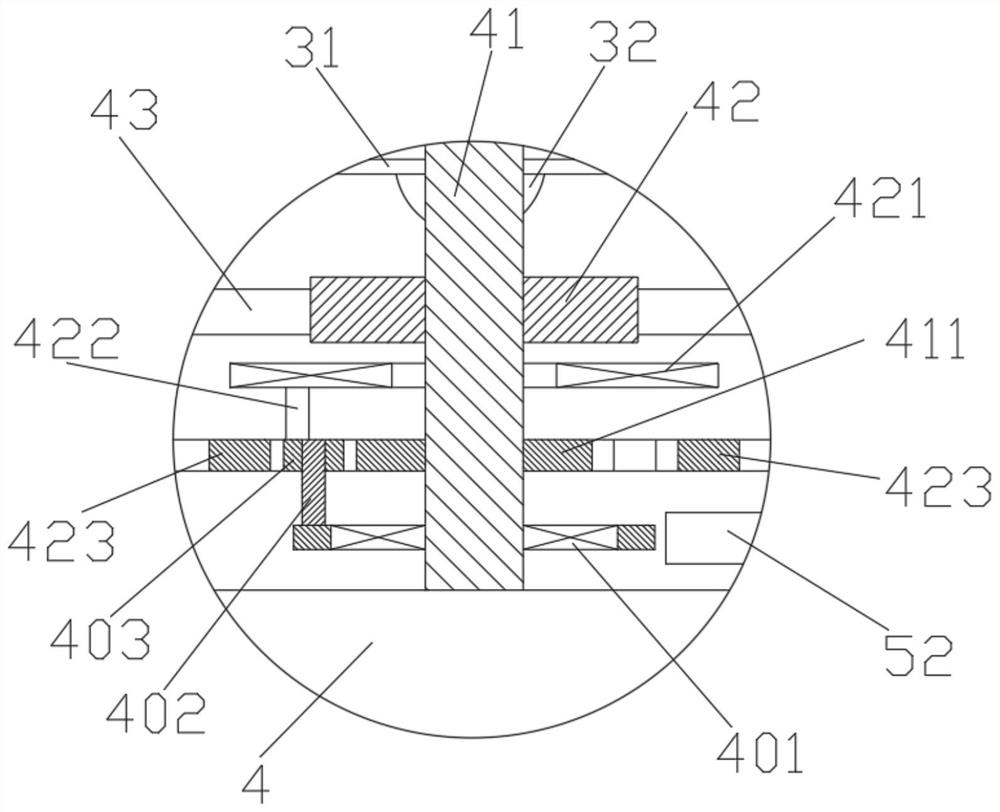

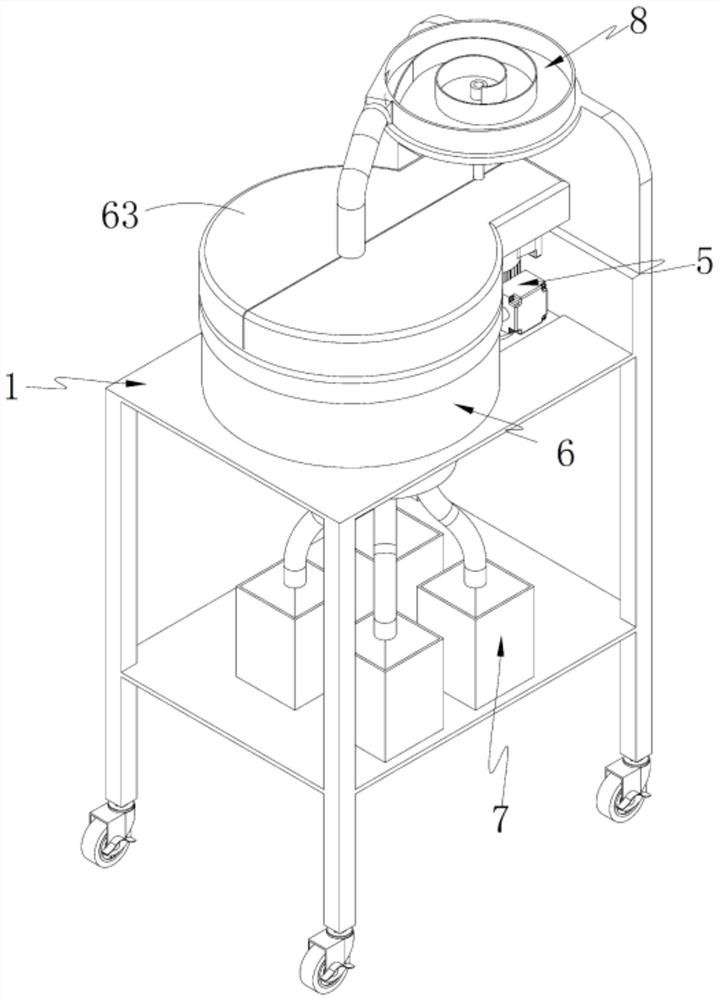

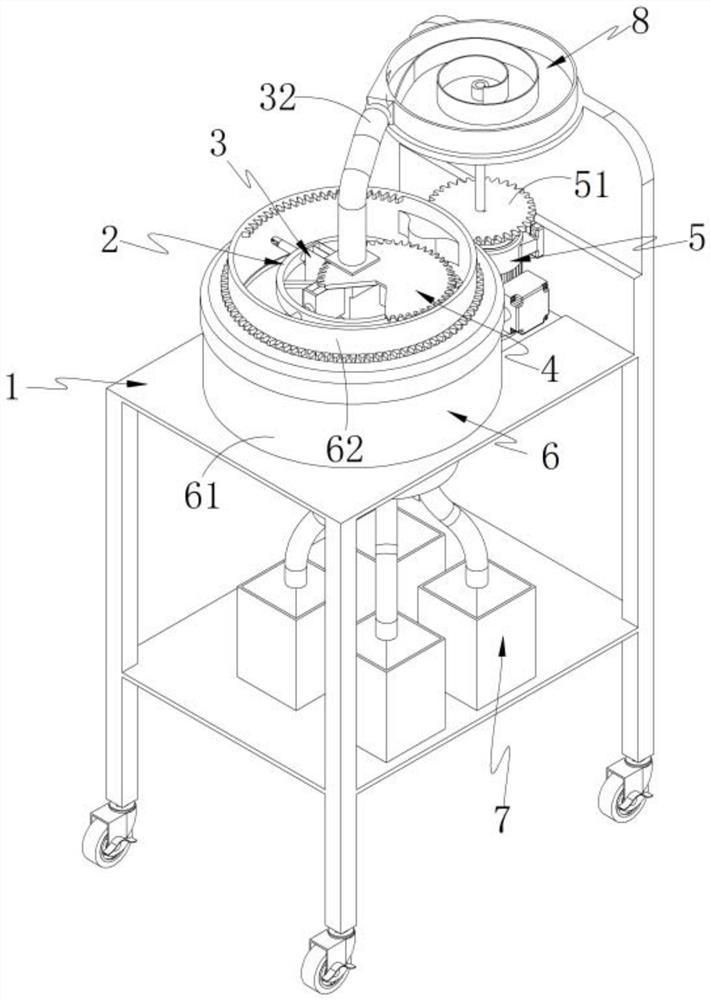

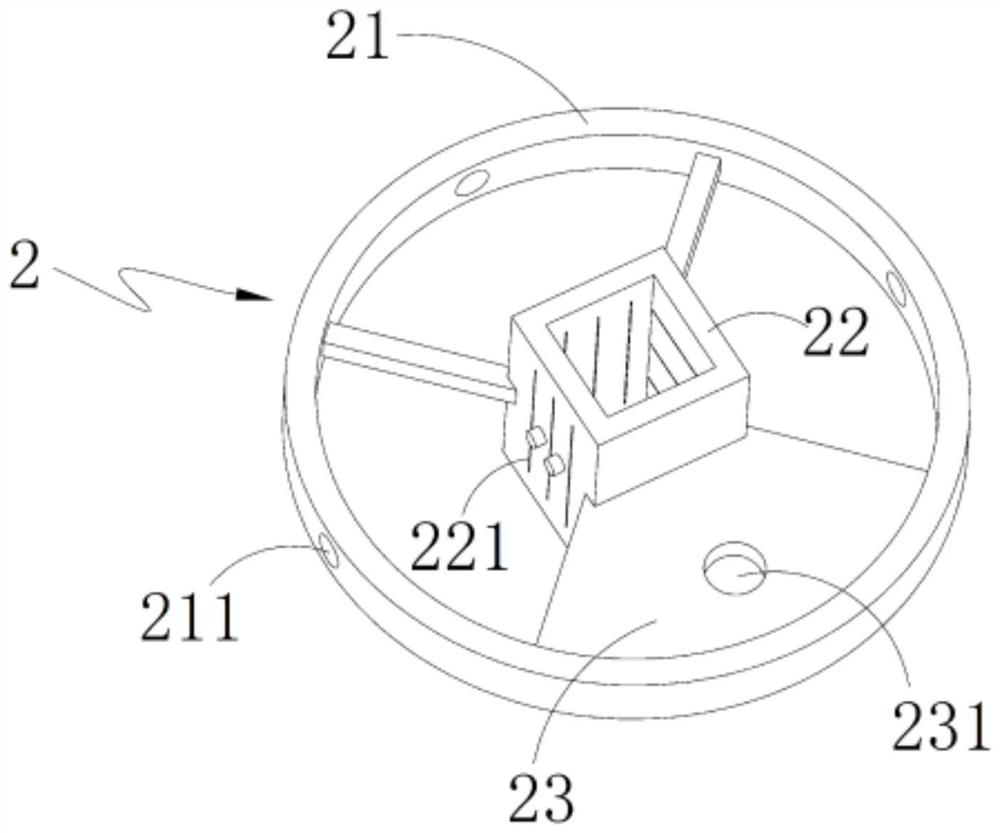

Crushed peanut processing equipment capable of reducing residual oil

ActiveCN112718142ASynchronous cuttingReduce residual oilRotary centrifugesGrain treatmentsAgricultural engineeringProcess engineering

The invention provides crushed peanut processing equipment capable of reducing residual oil. The equipment comprises a rack, a knife rest unit, a cutter, a feeding control unit, a driving unit, a material cutting control unit, a material receiving unit and an oil draining unit, and is characterized in that a spiral oil draining pipe of which a spiral direction is opposite to a rotating direction of a conical rotating disc is arranged on the oil draining unit, so that oil draining and sorting of fried peanuts are achieved, and the peanuts subjected to oil draining sequentially enter a knife rest; the feeding control unit, the knife rest unit, the cutter and the material cutting control unit cooperate with one another, so that the peanuts are cut according to a required particle size, and the problem that the particle uniformity of crushed peanuts is poor due to the fact that the crushed peanuts are produced in a crushing mode is solved; and the crushed peanuts with different particle sizes are classified and collected by means of the material receiving unit, the crushed peanuts with the different particle sizes are independently packaged and sold, the requirements of different customers are met, and a yield of the crushed peanuts is increased.

Owner:阜阳佰恩得新材料技术有限公司

Pitaya flower drying technology

InactiveCN106306252ANeat flower bodyWhiteningTea substituesFood preservationPre treatmentFood flavor

The invention discloses a pitaya flower drying technology and belongs to the technical field of drying. According to the pitaya flower drying technology, dried pitaya flowers are obtained through the steps of picking, pretreatment, selecting and arranging, drying, packaging and the like. The pitaya flowers obtained with the technology are pretreated with steam before drying and then treated with an automatic segmented drying technology, the moisture content is effectively reduced, no additive is added, and thus the dried pitaya flowers have uniform flower bodies, and are mild and white in color, free of fragments, aromatic in flavor and high in vitamin preservation rate.

Owner:广西冠强农业开发有限责任公司

High-frequency vibrating sponge perforating device and application thereof

InactiveCN105773679AProcessing is of great significanceHigh precision of aperture sizeMetal working apparatusTransformerEngineering

The invention particularly relates to a high-frequency vibrating sponge perforating device and application thereof. The high-frequency vibrating sponge perforating device is mainly used for processing an elastic layer on a transfer roller in a printer or copier and comprises an ultrasonic generator, an ultrasonic transducer connected with the ultrasonic generator through wires, at least one amplitude transformer connected with the ultrasonic transducer and a tubular tool connected with the amplitude transformer, wherein the tubular tool is in threaded connection with the amplitude transformer and comprises a connector connected with the amplitude transformer, a tube body with an inner cavity and a cutting edge; one end of the tube body is in threaded connection with the connector; the cutting edge is arranged at the other end of the tube body; and a circular arc transition structure is arranged at the joint of the tube body and the connector. Through the technical scheme provided by the invention, the high-frequency vibrating sponge perforating device perforates sponge easily, a perforating process is stable, the dimensional accuracy of holes is high, the surfaces of hole walls are smooth and free of damage, the product percent of pass is greatly increased, and the production efficiency is remarkably improved.

Owner:SUZHOU UNIV OF SCI & TECH +1

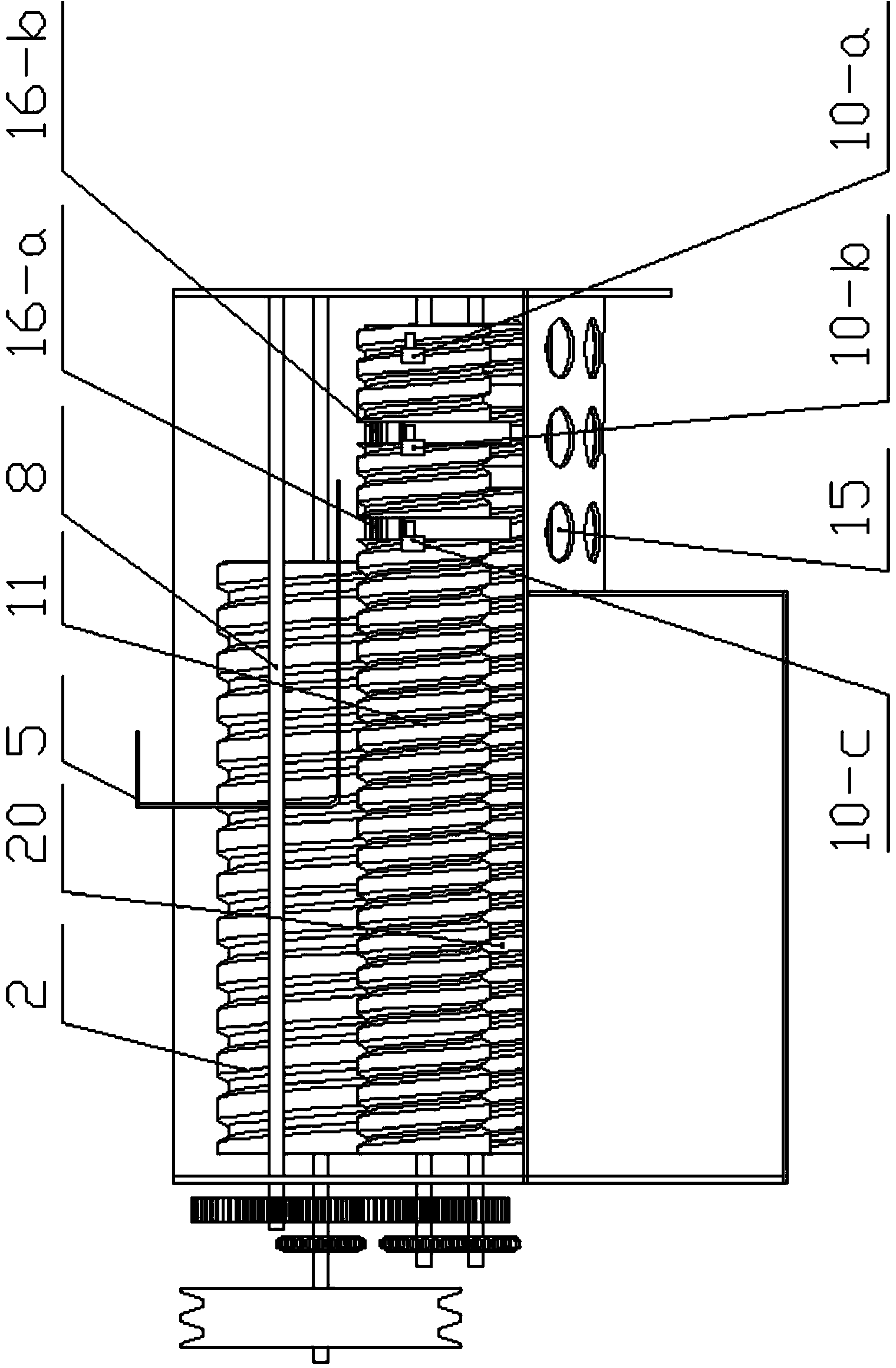

Production line for manufacturing crushed peanuts

ActiveCN112718139ASolve the problem of excessive residual oilUniform particlesRotary centrifugesGrain treatmentsProcess engineeringIndustrial engineering

The invention provides a production line for manufacturing crushed peanuts. The production line comprises a rack, a knife rest unit, a slicer unit, a driving unit, a slicing control unit, a discharge control unit, a receiving unit and an oil draining unit. First, oil of the fried peanuts are drained by using the oil draining unit, so that the problem that the fried crushed peanuts are excessive in residual oil is solved; the peanuts after oil drainage are output along a spiral oil drainage pipe, and meanwhile, the peanuts are sequenced simultaneously, so that the peanuts enter the knife rest unit successively, and therefore, the crushed peanuts are uniform in particle size; the peanuts are sliced according to demanded particle sizes by matching the slicer unit and the slicing control unit, so that the problem of poor particle size uniformity as the crushed peanuts are produced in a crushed manner is solved. The crushed peanuts of different particle sizes are collected in a classified manner by the receiving unit, so that the crushed peanuts of different particle sizes are packaged and sold independently, and therefore, the demands of different clients are met and the yield of the peanuts is improved.

Owner:阜阳佰恩得新材料技术有限公司

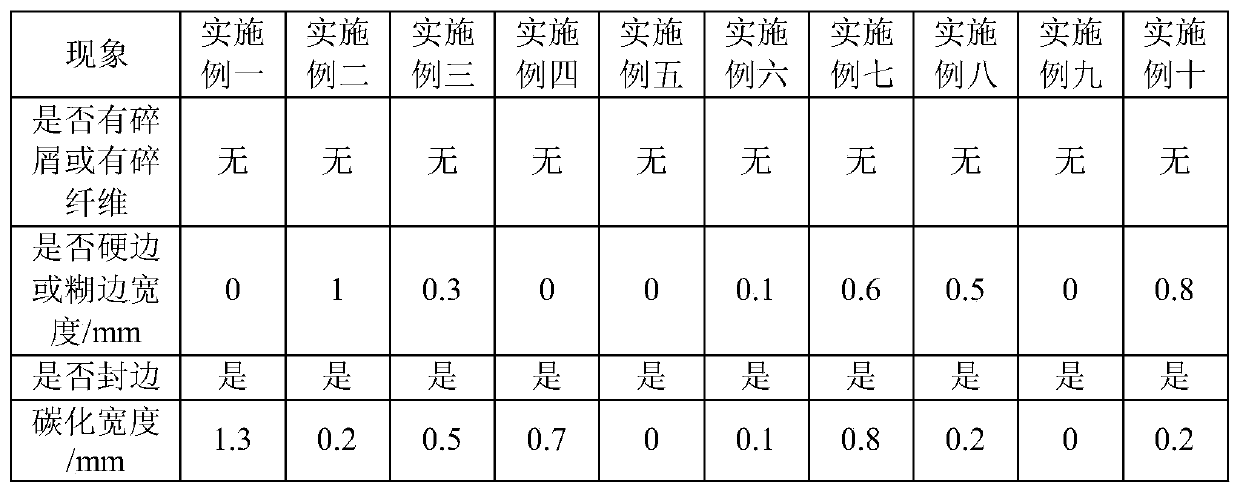

Cutting process of PVA (polyvinyl alcohol) composite

ActiveCN110144725AReduce generationReduce dropSevering textilesMetal working apparatusFiberDecomposition

The invention discloses a cutting process of a PVA (polyvinyl alcohol) composite and relates to the field of PVA processing. According to a main technical scheme, PVA woven fabric, PVA non-woven fabric or a PVA film is cut along a set trim with a heating cutting or through ultrasonic wave or laser to separate the corresponding PVA woven fabric, the PVA non-woven fabric or the PVA film. By means ofthe technical scheme, on one hand, the melting point of PVA is close to the decomposition temperature of PVA, and therefore, PVA can be molten and decomposed in the cutting process through the heating cutter, ultrasonic wave or laser, so that a formed cutting edge cannot have chips and no broken fiber falls off; besides, due to the poor PVA melting processing performance and low flowability in amolten state, and the heat conductivity of the cutting behavior is very small, which is shown by the fact that the edge of a material formed by cutting cannot get hard.

Owner:HUNAN XINJINFU MEDICAL TECH CO LTD

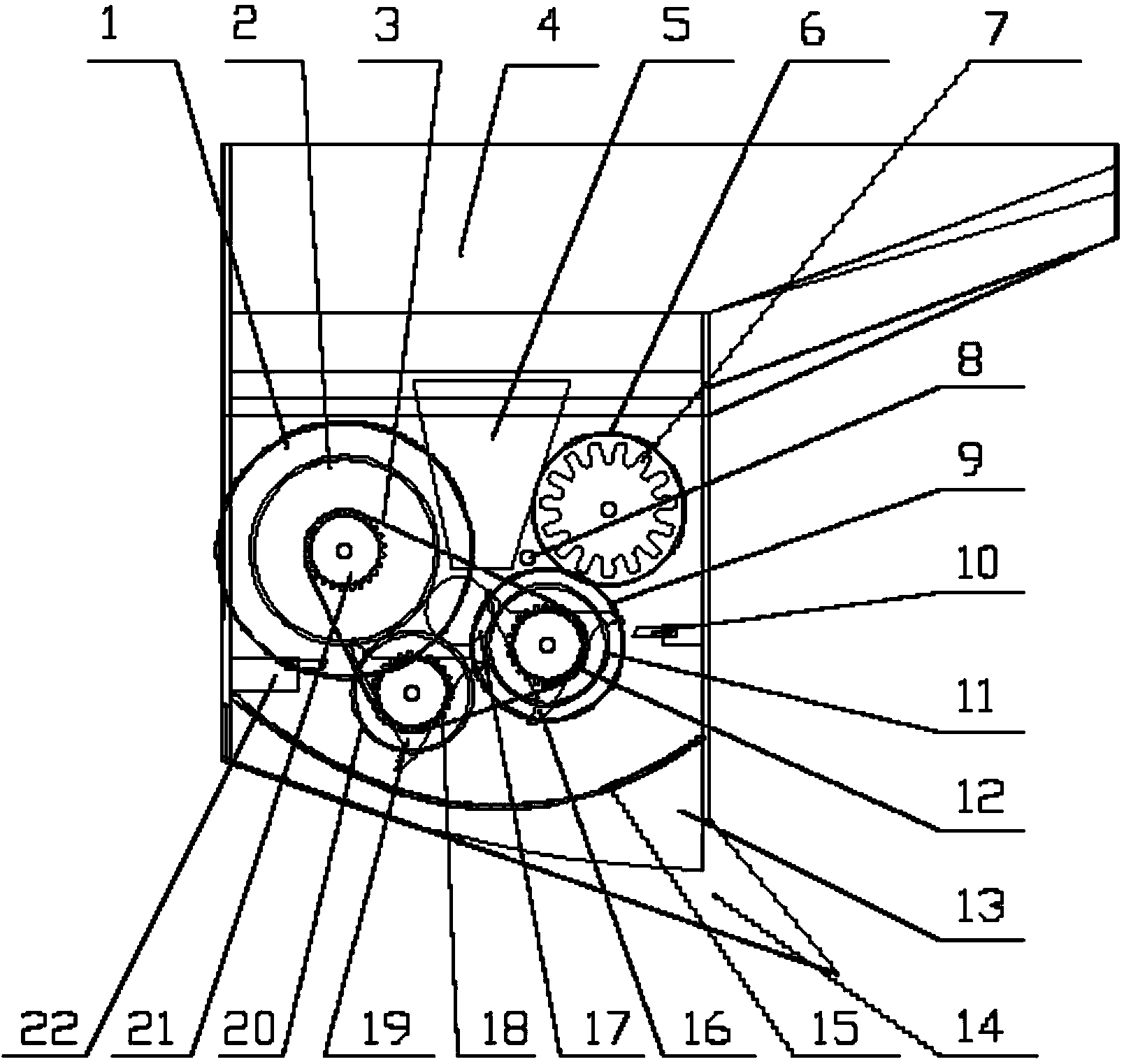

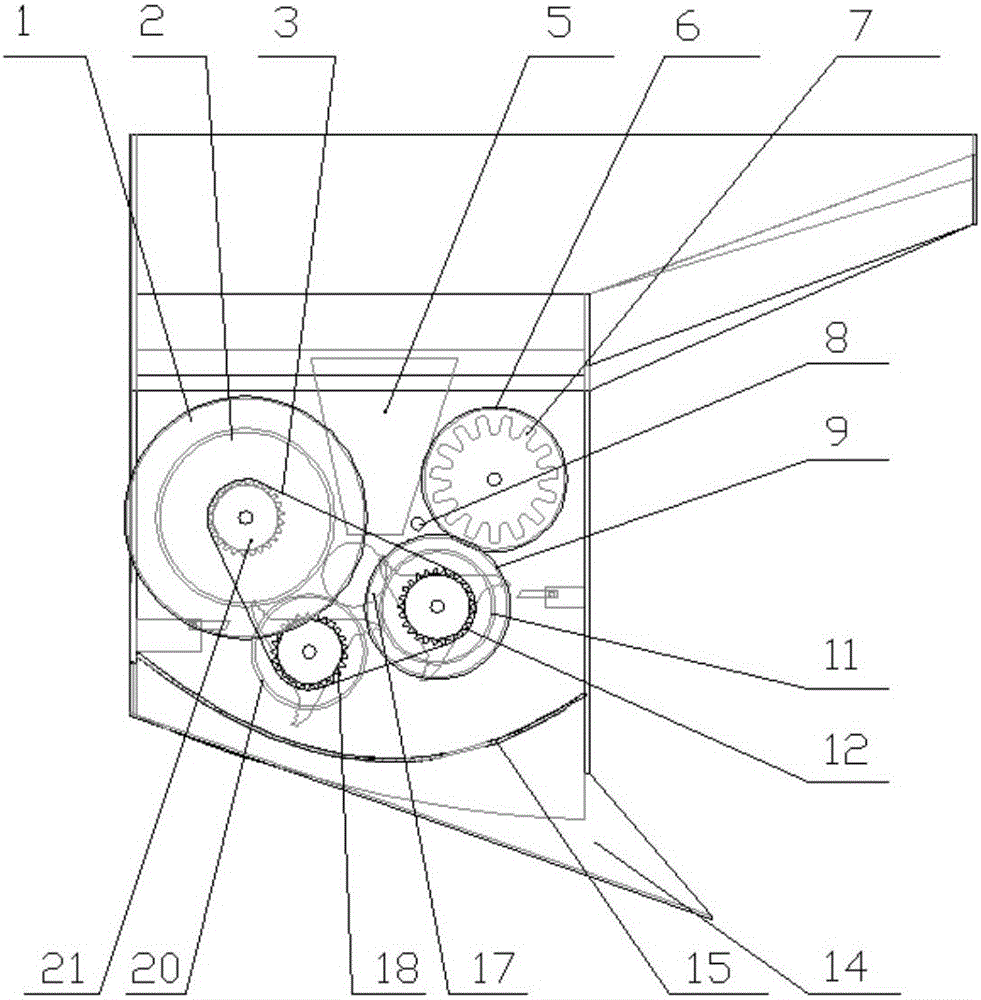

Corn threshing and cob breaking machine

InactiveCN103814704AReasonable structural designHigh threshing rateThreshersGrain treatmentsEngineeringThreshing

The invention discloses a corn threshing and cob breaking machine which comprises a threshing chamber and a cob breaking chamber. The threshing chamber and the cob breaking chamber are located in different positions of a same overall chamber. A corn threshing mechanism is arranged in the threshing chamber and comprises four rollers different in diameter. The rollers include a large spiral tooth roller, a straight tooth roller, a small spiral tooth roller and a slag discharging spiral tooth roller, and the big-end-up V-shaped space is formed among the rollers, an L-shaped pressure baffle plate is arranged under a corn threshing and feeding port, a binding is arranged on one side, of a gap between the straight tooth roller and the small spiral tooth roller, inside the machine, a corn cob discharging outlet is arranged in an end plate, and a corn kernel discharging outlet is arranged under the threshing chamber; a corn cob breaking mechanism is arranged in the cob breaking chamber and comprises fixed cutters and movable cutters, the fixed cutters arranged on a box and the movable cutters arranged on two rotary screw roller sets are distributed inside the cob breaking chamber, and a corn cob discharging leaking screen is arranged on the lower end face of the corn breaking chamber. The corn threshing and cob breaking machine is reasonable in design, high in threshing rate, undamaged to corn kernels, free of corn cob crumbs, even in cob breaking, small in size and light in weight.

Owner:ANHUI AGRICULTURAL UNIVERSITY

A kind of polyethylenedioxythiophene nanotube array and preparation method and application thereof

InactiveCN103343377BImprove conductivityImprove solubilitySurface reaction electrolytic coatingElectrophoretic coatingsOrganic filmTio2 nanotube

The invention discloses a polyethylenedioxythiophene nanotube array and its preparation method and application. The array is polyethylenedioxythiophene with neatly arranged nanotubes arranged in an array. At least one end of the nanotube is Transparent, the array is insoluble in water, transparent, and conductive. The preparation method includes the following steps in sequence: secondary anodic oxidation to obtain independently separated TiO2 nanotube arrays; using the independently separated TiO2 nanotube arrays as anodes and platinum wires as cathodes, performing constant potential or constant current electropolymerization to obtain selective in The TiO2 nanotube array tube and the tube space are filled with polyethylenedioxythiophene composite material, and the TiO2 nanotube array is removed with hydrofluoric acid to obtain polyethylenedioxythiophene with neatly ordered nanotubes arranged in an array. The composite material can be used as a transparent electrode material, and can be applied in the fields of organic thin-film solar cells, antistatic coatings, organic optoelectronics, electrochromism, and solid electrolytic capacitors.

Owner:SICHUAN AGRI UNIV

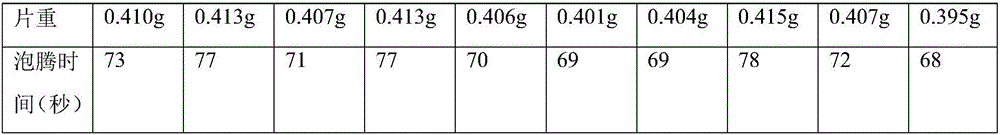

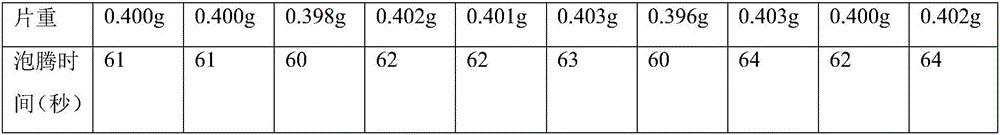

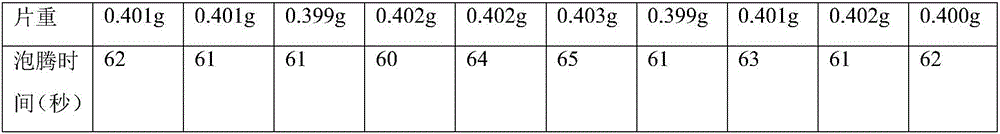

BCAA (branched-chain amino acid) effervescent tablet and preparation method thereof

InactiveCN106343318APleasant tasteEasy to filmFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentEffervescent tabletCarboxymethyl starch

The invention discloses a BCAA (branched-chain amino acid) effervescent tablet and a preparation method thereof. The effervescent tablet comprises the following components in parts by weight: 40 to 60 parts of instant BCAA powder, 8 to 12 parts of erythritol, 6 to 10 parts of fruit powder, 5 to 10 parts of citric acid, 5 to 10 parts of sodium bicarbonate, 4 to 8 parts of sodium carboxymethyl starch, 0.1 to 0.3 part of a sweetening agent and 0.3 to 0.5 part of essence. The components are mixed for 15 to 25 minutes by a three-dimensional machine and are tabletted. The BCAA effervescent tablet provided by the invention is quick in response, easy to absorb, convenient to carry and drink and good in taste.

Owner:江苏阜丰生物科技有限公司

Door and window glass emergency cutter

InactiveCN106735932AEasy to carryImprove laser efficiencyWelding/soldering/cutting articlesLaser beam welding apparatusKey pressingLiquid-crystal display

The invention discloses a door and window glass emergency cutter which comprises a laser cutter shell and a CO2 laser. A laser control chamber, a partition and a working chamber are mounted in the laser cutter shell, an AVR single-chip microcomputer, a storage battery and a laser controller are mounted in the laser control chamber, the CO2 laser is mounted in the working chamber, a laser outlet is formed in center of the bottom of a light-gathering cavity, the light-gathering cavity is connected with a micro-fan through an auxiliary gas delivery pipe, and opening and closing buttons, a liquid crystal display and function buttons are mounted at the top end of the laser cutter shell. According to the emergency cutter, laser emitted by the CO2 laser can be aggregated by the aid of a focus lens, the laser generating efficiency of the CO2 laser is improved, the cut glass cannot generate cracks, the power of the laser is improved by adjusting the function buttons, the glass is rapidly cut, and the cutter is particularly suitable for emergency cutting of the door and window glass.

Owner:CHONGQING HUARUI GLASS CO LTD

A production line for making crushed peanuts

ActiveCN112718139BSolve the problem of excessive residual oilUniform particlesRotary centrifugesGrain treatmentsProcess engineeringManufacturing line

The invention provides a production line for making crushed peanuts, which includes a frame, a knife holder unit, a cutter unit, a driving unit, a material cutting control unit, a material discharging control unit, a material receiving unit and an oil draining unit. First, the oil draining unit is used. Draining the fried peanuts solves the problem of excessive residual oil after frying; the drained peanuts are output along the spiral oil draining pipe, and the sorting of the peanuts is completed at the same time, so that the peanuts enter the knife holder unit in turn. , to ensure the uniformity of the peanuts after being chopped; using the mutual cooperation between the cutter unit and the cutting control unit to cut the peanuts according to the required particle size, which solves the problem of poor particle uniformity caused by crushing peanuts. The problem; using the receiving unit to classify and collect peanut fragments of different particle sizes, realize the separate packaging and sales of peanut fragments of different particle sizes, meet the needs of different customers, and improve the yield of peanut fragments.

Owner:阜阳佰恩得新材料技术有限公司

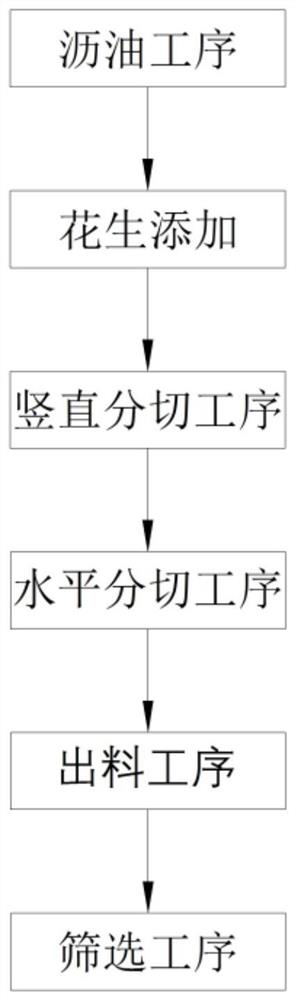

Manufacturing method for crushed peanuts

ActiveCN112718141ASolve the problem of excessive residual oilUniform particlesRotary centrifugesGrain treatmentsProcess engineeringIndustrial engineering

The invention provides a manufacturing method for crushed peanuts. The crushed peanuts are manufactured by a slitting manner as fried peanuts are subjected to an oil draining step, a peanut adding step, a vertical slitting step and a horizontal slitting step, so that the problem of disintegrating slag of the crushed peanuts manufactured by a crushing manner and low yield is solved. A discharging step is matched with a screening step, so that the crushed peanuts of different particle sizes are stored in a classified manner after being discharged, and thereby, the demands of different clients on the particle size are met.

Owner:山东华程乐畅食品有限公司

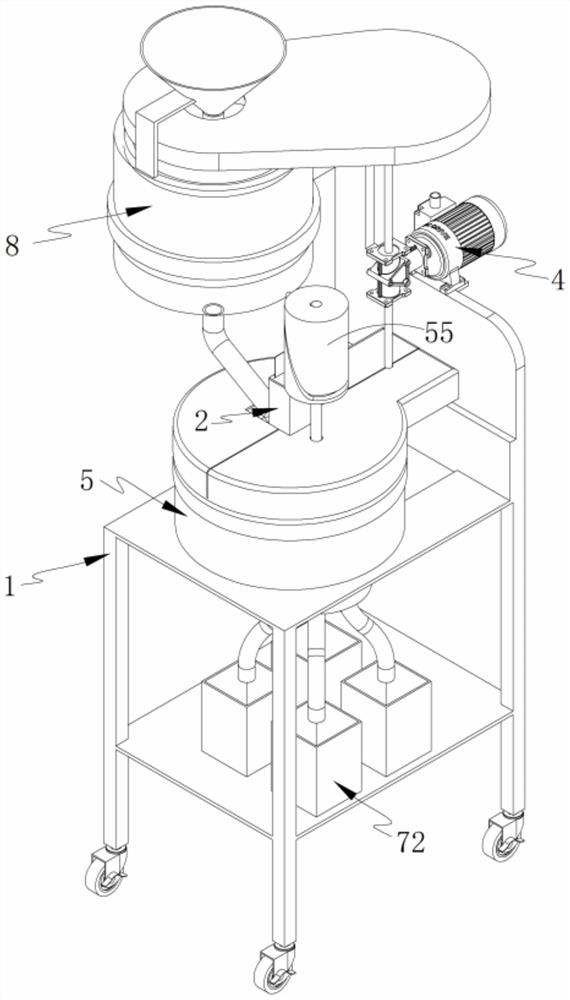

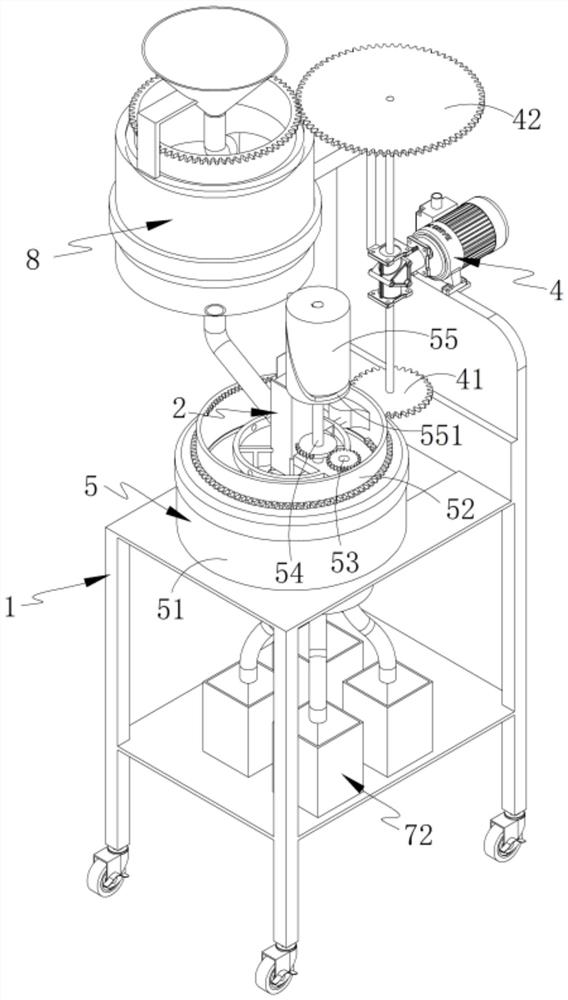

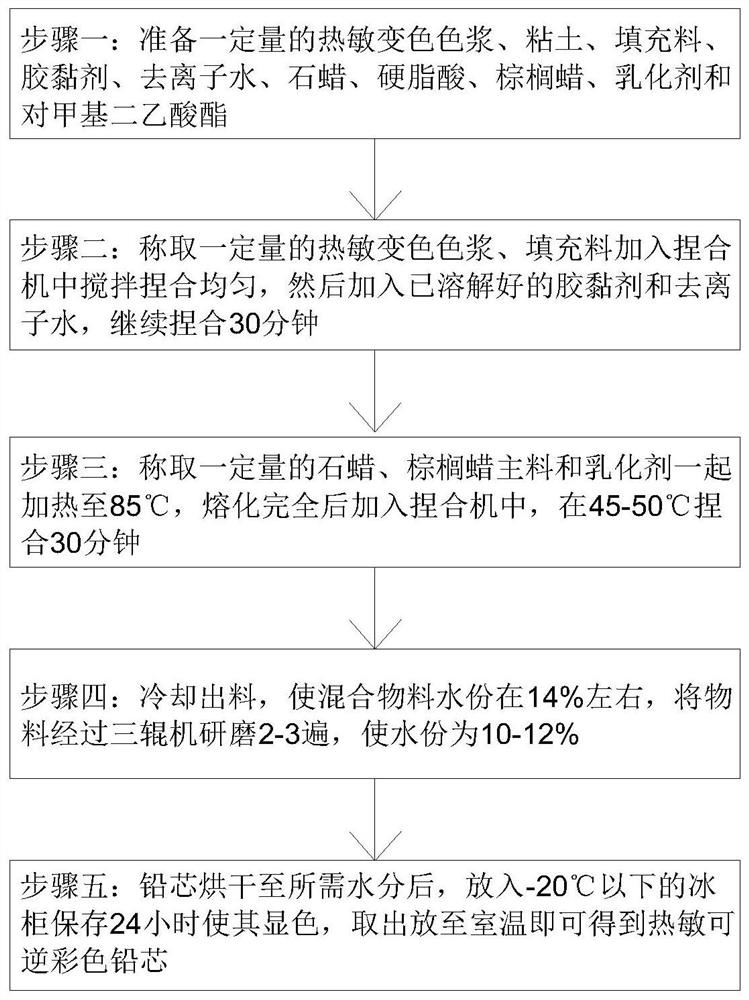

Preparation process of thermosensitive color-changing pencil lead

The invention discloses a preparation process of a thermosensitive color-changing lead core. The preparation process is mainly prepared from the following raw materials: thermosensitive color-changing color paste, clay, a filler, an adhesive, deionized water, paraffin, stearic acid, palm wax, an emulsifier and p-methyldiacetate, and the material is simple in structure and novel in design, and has the characteristics of color display at normal temperature, when the pencil lead is heated to a certain temperature, the color disappears completely, the pencil lead is still colorless when the temperature returns to the normal temperature from the high temperature, the color returns to the original colored state when the temperature continues to be reduced to the critical temperature (color developing temperature), and meanwhile the pencil lead has the advantages of being smooth in writing, easy to color and not prone to breakage.

Owner:LOTUS STATIONERY

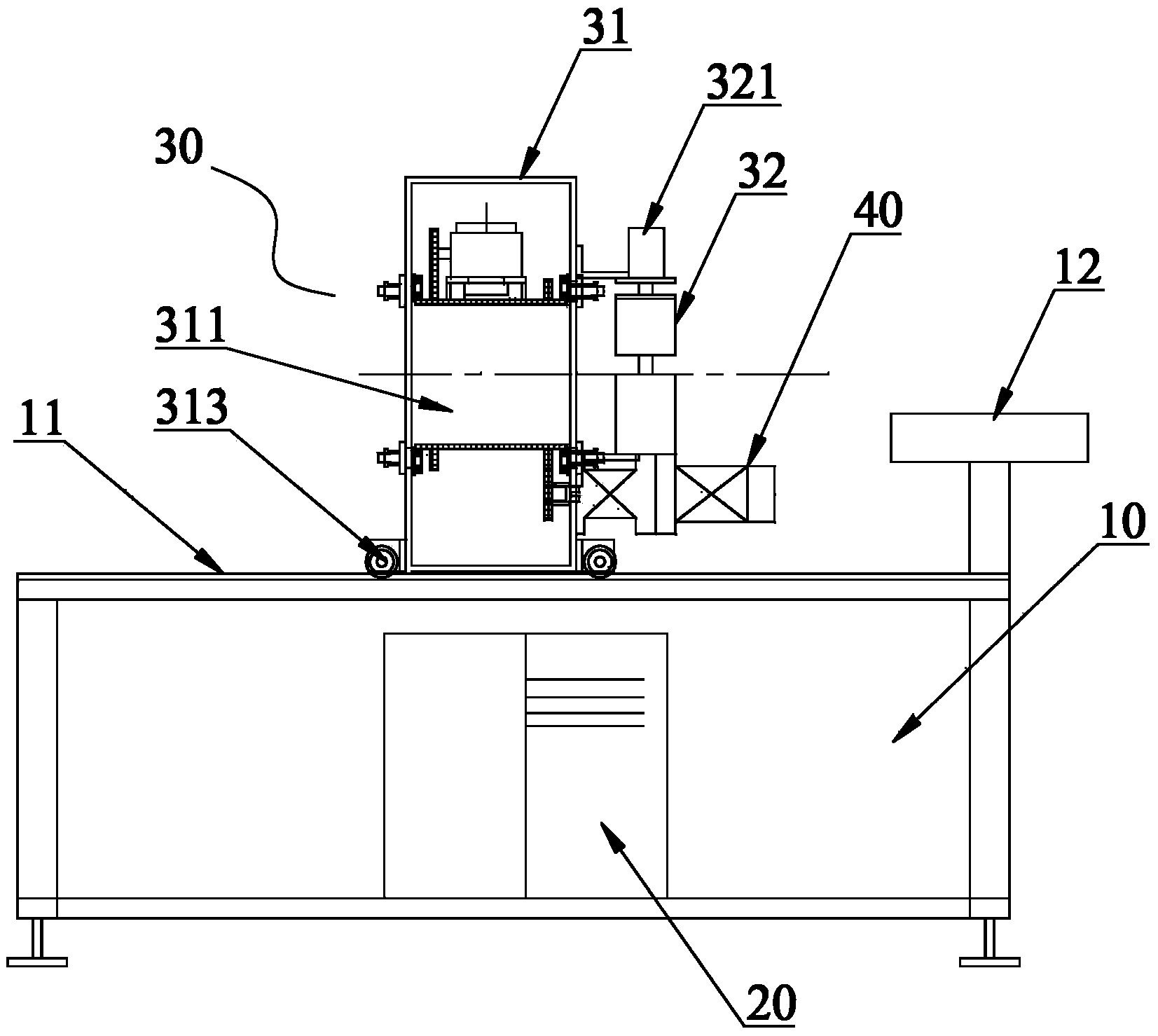

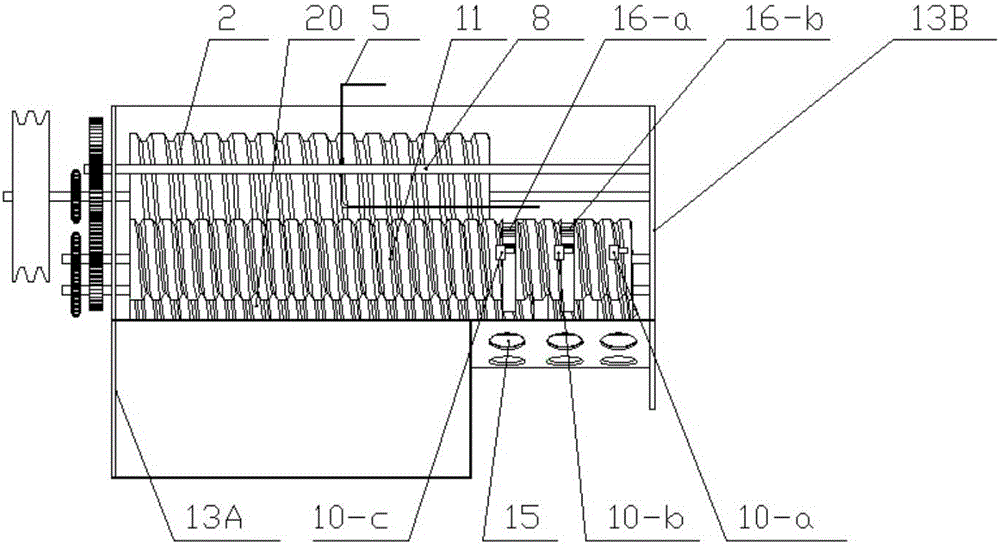

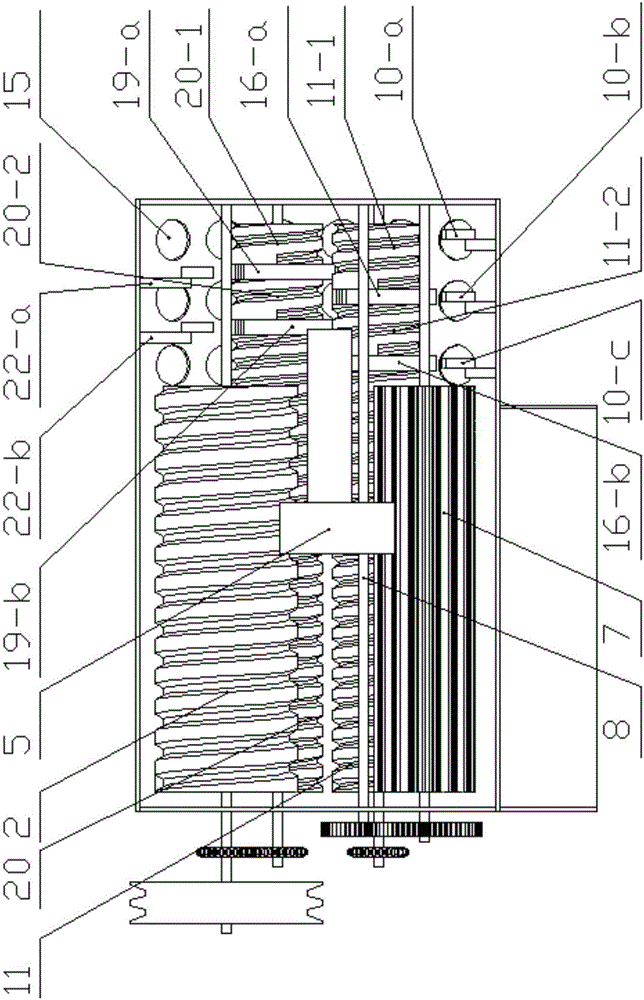

Automatic cutting machine for PVC (polyvinyl chloride) finned tubes

The invention relates to an automatic cutting machine for PVC (polyvinyl chloride) finned tubes. The automatic cutting machine comprises a bench, an electric cabinet, a cutting unit and a cutting motor. The electric cabinet is fixed on the bench. The cutting unit is mounted on the top of the bench and connected with the electric cabinet. The cutting motor is connected with the electric cabinet. The cutting unit comprises a cutter and a clamping device. The center of the cutter is provided with a round hole admitting passage of a PVC finned tube. The clamping device is disposed on the cutter and locates on the axial part of the round hole. The cutting unit is provided with provided with a drum locating on the inner wall of the round hole. The drum is provided with a cutting tool and connected with the cutting motor. The automatic cutting machine has the advantages that the machine is automated for cutting the PVC finned tubes, is handy and fast and is high in cutting efficiency; damage to cuts is avoided during the cutting process; cutting is even, with no chips occurring; the cost is saved, and the cutting quality is improved; manual cutting is avoided so that labor resources are saved greatly.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

A corn threshing machine

The invention discloses a corn threshing and cob breaking machine which comprises a threshing chamber and a cob breaking chamber. The threshing chamber and the cob breaking chamber are located in different positions of a same overall chamber. A corn threshing mechanism is arranged in the threshing chamber and comprises four rollers different in diameter. The rollers include a large spiral tooth roller, a straight tooth roller, a small spiral tooth roller and a slag discharging spiral tooth roller, and the big-end-up V-shaped space is formed among the rollers, an L-shaped pressure baffle plate is arranged under a corn threshing and feeding port, a binding is arranged on one side, of a gap between the straight tooth roller and the small spiral tooth roller, inside the machine, a corn cob discharging outlet is arranged in an end plate, and a corn kernel discharging outlet is arranged under the threshing chamber; a corn cob breaking mechanism is arranged in the cob breaking chamber and comprises fixed cutters and movable cutters, the fixed cutters arranged on a box and the movable cutters arranged on two rotary screw roller sets are distributed inside the cob breaking chamber, and a corn cob discharging leaking screen is arranged on the lower end face of the corn breaking chamber. The corn threshing and cob breaking machine is reasonable in design, high in threshing rate, undamaged to corn kernels, free of corn cob crumbs, even in cob breaking, small in size and light in weight.

Owner:ANHUI AGRICULTURAL UNIVERSITY

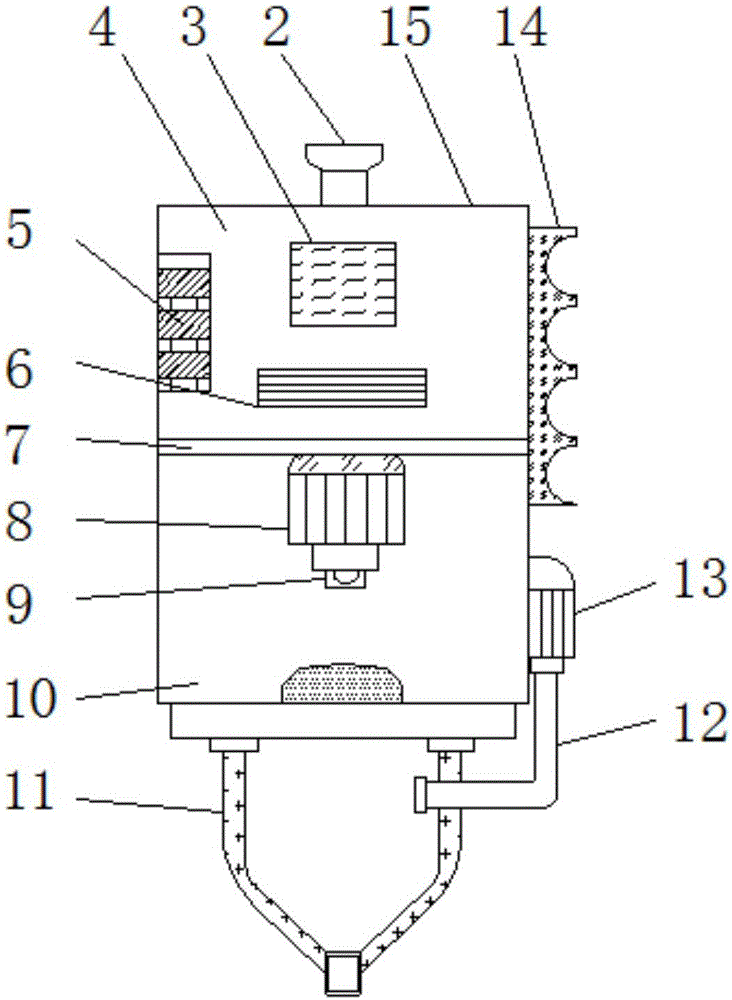

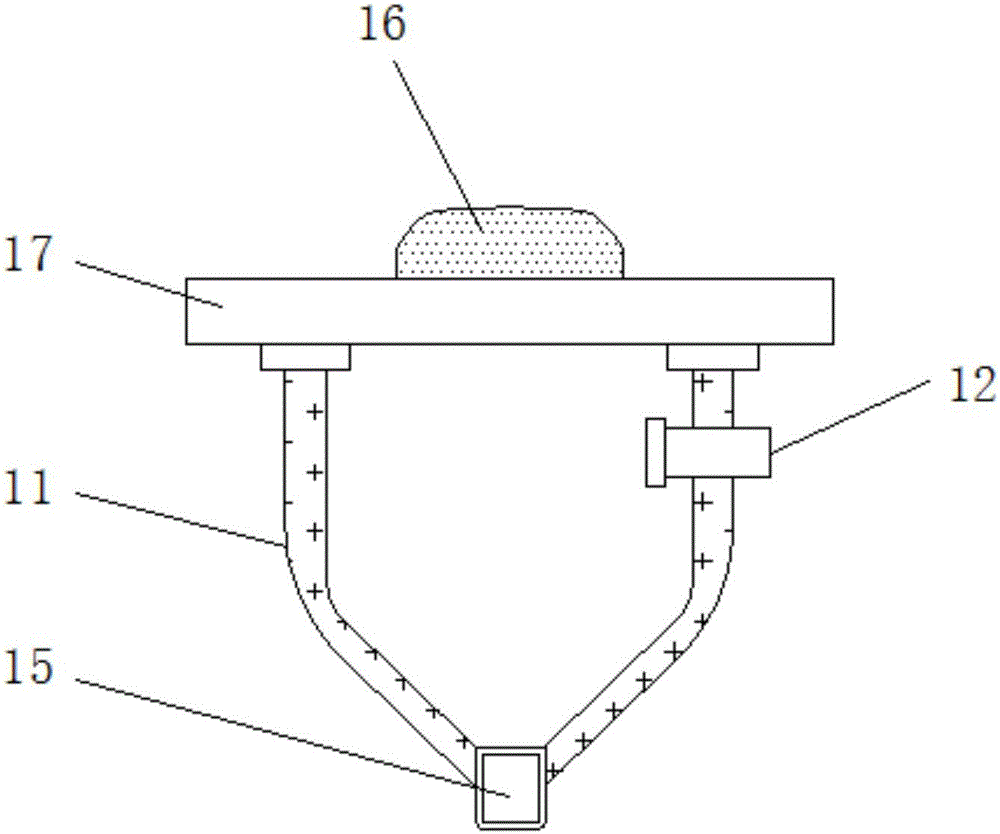

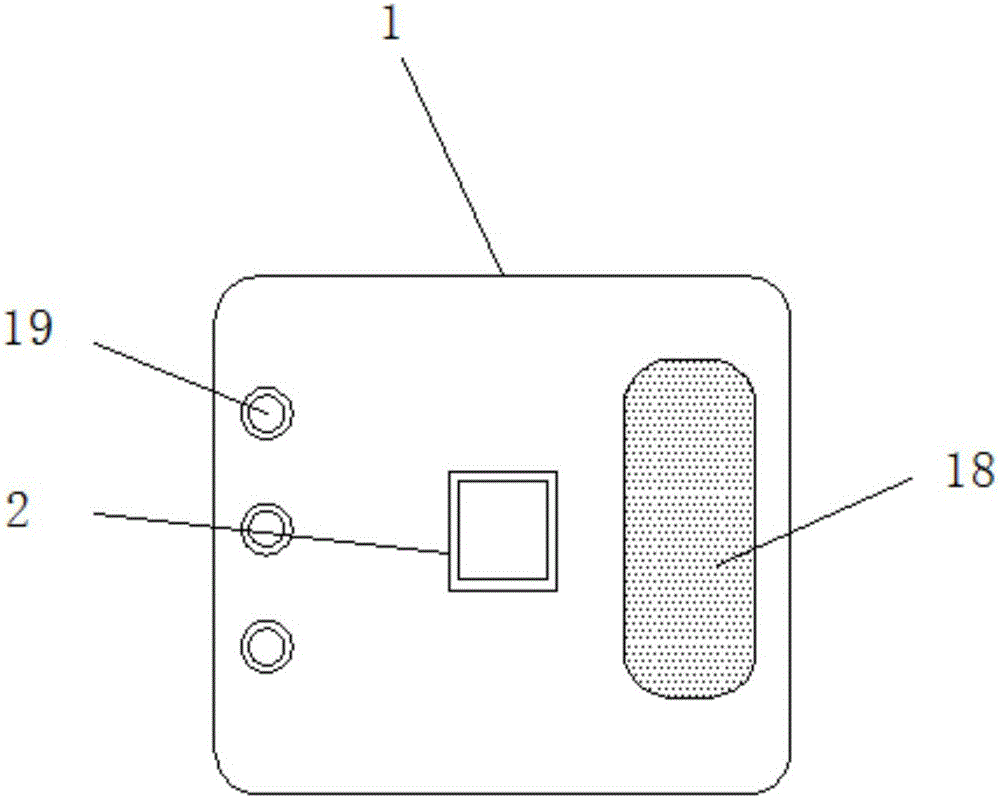

Tea processing equipment

InactiveCN112604961AFinish evenlyAvoid entanglementSievingPre-extraction tea treatmentBiotechnologyMechanical engineering

The invention discloses tea processing equipment which comprises a case, a partition plate is arranged in the middle of the case, screening equipment is mounted in the case above the partition plate, an enzyme deactivating device is mounted below the partition plate, a receiving barrel and a chip removal port are mounted on the partition plate, a chip removal pipe communicating with the exterior of the case is mounted on the chip removal port, the material receiving barrel is connected with the enzyme deactivating device, a heat insulation plate is further arranged on the inner wall of the case below the partition plate, an enzyme deactivating box is formed between the heat insulation plate and the bottom of the case, and an air inlet pipe and an air outlet pipe are arranged at the bottom of the enzyme deactivating box. The tea processing equipment overcomes the defects in the prior art, can automatically screen tea leaves and is high in screening efficiency, the quality of the screened tea leaves is controllable, meanwhile, the screened tea leaves can be tidied and subjected to enzyme deactivation, and the processed tea leaves are uniform, high in quality and free of chippings.

Owner:金寨县铁冲农业科技开发有限公司

Composite explosion-proof plate resisting high-speed fragments and high-strength explosion impact and manufacturing method

ActiveCN110202872BHigh strengthImprove toughnessLamination ancillary operationsProtective equipmentGlass fiberFiber

The invention discloses a composite explosion-proof board capable of shielding high speed broken sheets and high strength blasting impact. The composite explosion-proof board capable of shielding highspeed broken sheets and high strength blasting impact comprises a broken sheet damage layer, a buffer dispersion layer, and a structure support layer; the broken sheet damage layer is prepared from high strength constructional steel; the buffer dispersion layer is prepared from ultra high molecular polyethylene fiber; the structure support layer is composed of glass fiber and an epoxy composite material; the broken sheet damage layer, the buffer dispersion layer, and the structure support layer are laminated successively, and are bound using an epoxy adhesive. The structure is simple; the cost is low; manufacturing is convenient; shielding performance on high speed broken sheets and high strength blasting impact is excellent; and the composite explosion-proof board is an excellent explosion-proof material.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

A kind of processing equipment and method of crushed peanuts

ActiveCN112718140BThe chopping process is stableImprove pellet qualityGrain treatmentsGradingAgricultural engineeringProcess engineering

The invention provides a peanut crushed processing equipment and method, including a rack, a chopping unit, a cutter, a feeding control unit, a driving unit, a cutting control unit, a receiving unit and a sorting unit. Sort the peanuts into the chopping unit in turn to ensure that the peanuts are evenly chopped; the peanuts are cut to the required particle size by the cooperation between the feeding control unit, the chopping unit, the cutter and the cutting control unit. , the use of cutting knife to cut peanuts solves the problem of poor particle uniformity caused by crushing peanut crushing method; using the receiving unit to classify and collect peanut crushed peanuts with different particle sizes, and realize separate packaging and sales of peanut crushed peanuts with different particle sizes. , to solve the needs of different customers.

Owner:阜阳佰恩得新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com