Quick crosslinked ethylene-vinyl acetate copolymer (EVA) adhesive film for double-glazed module, and preparation method of EVA adhesive film

A double-glass module, cross-linked technology, applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of long lamination time, light transmittance and shrinkage effects, cell displacement and other issues, to achieve the effect of reducing the cost of electricity, reducing production costs, and eliminating shifting and merging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

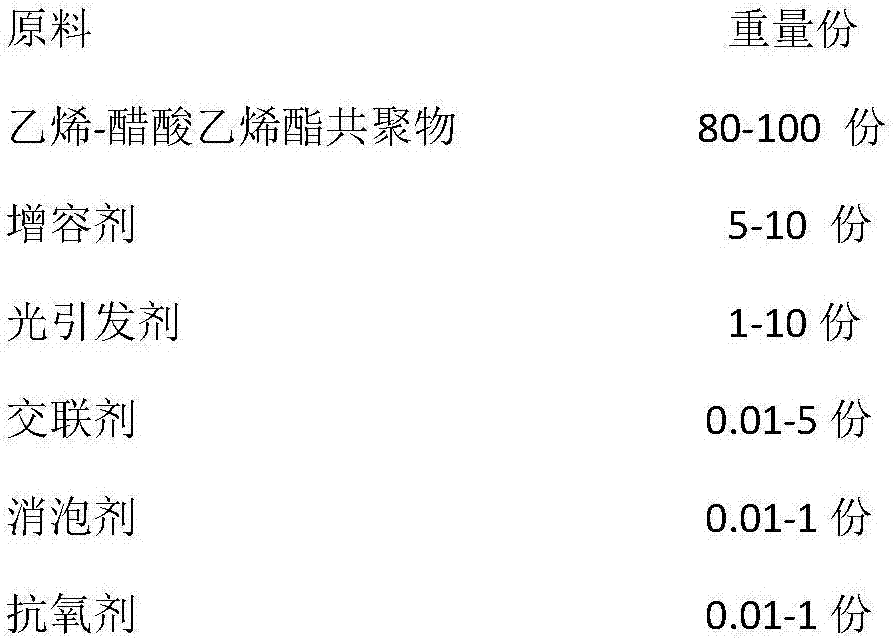

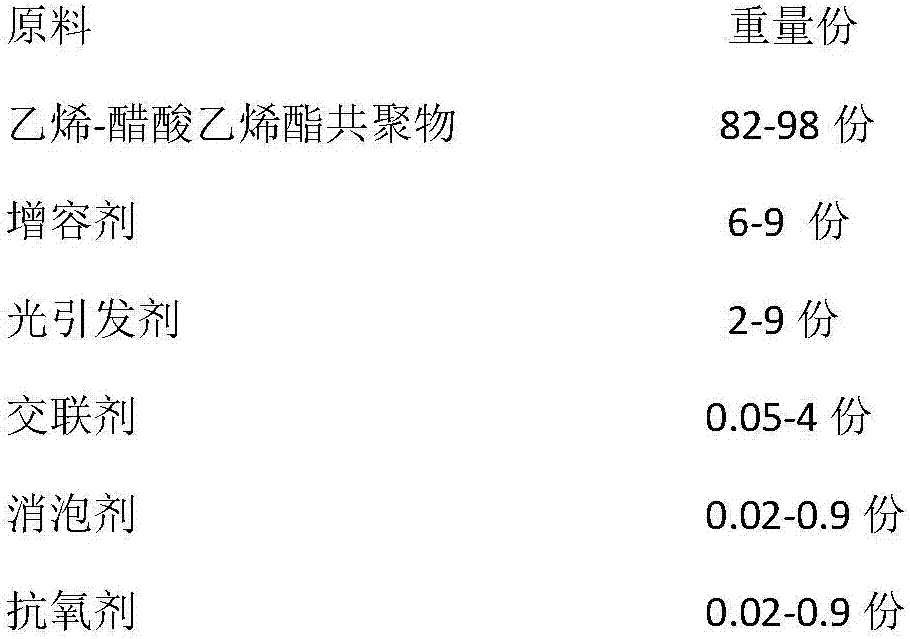

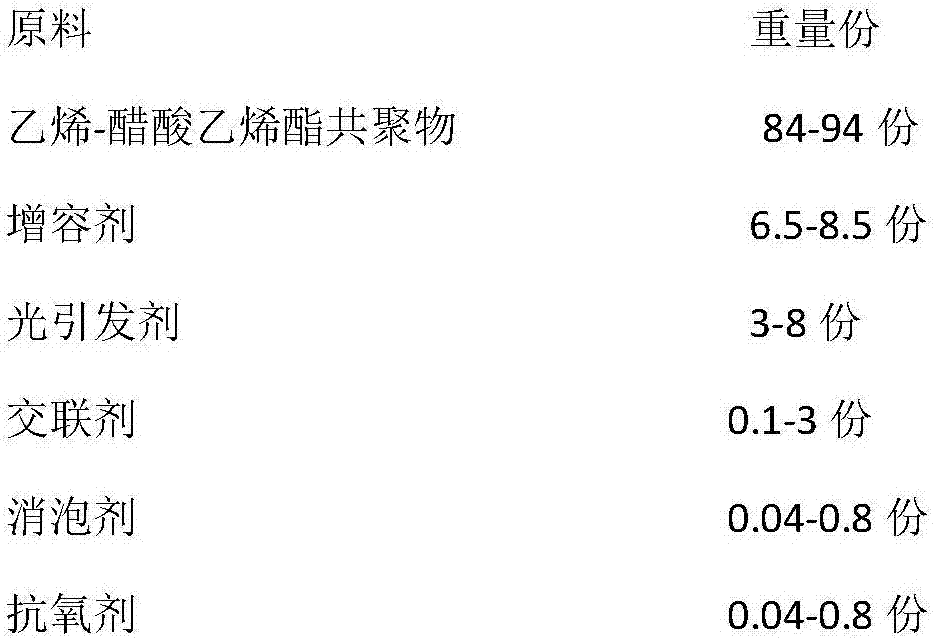

[0045] A fast-crosslinking type EVA film for double-glass components, which is made of the following raw materials in parts by weight:

[0046] raw material

Parts by weight (consumption kg)

EVA resin (ethylene vinyl acetate copolymer)

100

2-Hydroxy-2-methyl-1-phenylacetone

3

EVA-MAH compatibilizer

1

tert-Butyl peroxy-isopropyl carbonate

1.5

0.1

0.5

[0047] A kind of preparation method of fast cross-linking type EVA adhesive film for double glass module, its steps are:

[0048]A. Mix ethylene-vinyl acetate copolymer with photoinitiator, crosslinking agent, compatibilizer, defoamer and antioxidant;

[0049] B. After mixing the raw materials in step A evenly in the high mixer, put them into the extruder for mixing, and the temperature of the extruder is controlled at 80 or

[0050] 90 or 100 or 110 or 120°C,

Embodiment 2

[0054] A fast-crosslinking type EVA film for double-glass components, which is made of the following raw materials in parts by weight:

[0055] raw material

[0056] Its preparation steps are identical with embodiment 1. Obtain a film thickness of 0.6 mm.

Embodiment 3

[0058] raw material

[0059] Its preparation steps are identical with embodiment 1. Obtain a film with a thickness of 0.7 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com