A kind of polyethylenedioxythiophene nanotube array and preparation method and application thereof

A technology of polyethylenedioxythiophene and ethylenedioxythiophene is applied in nanotechnology, surface reaction electrolytic coating, electrophoretic plating, etc., and can solve the problem of not preparing polyethylenedioxythiophene nanotube arrays, etc. Achieve the effect of small energy gap, high photoelectric performance and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

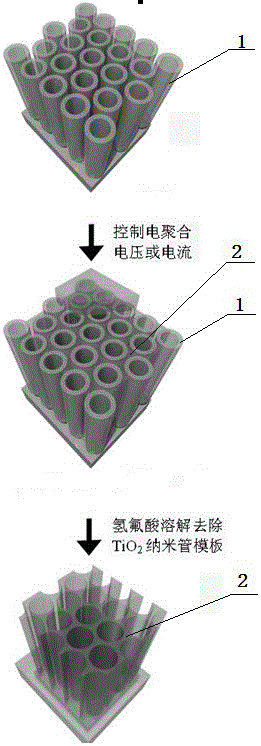

[0032] The preparation method of polyethylene dioxythiophene nanotube array, comprises the steps:

[0033] (1) High-purity (above 99.5%) titanium sheets or titanium screens are pretreated (ultrasonic cleaning and drying in acetone, ethanol and distilled water, respectively) as anodes, and high-purity (above 99.5%) graphite rods are used as cathodes. Use 1,3 dimethylimidazolium tetrafluoroborate and water as the electrolyte, the mass ratio of water is 1%, anodize at 20V voltage, after 3 hours of reaction, rinse with deionized water to remove the residual electrolyte on the surface, use Scotch tape was used to remove the oxide film on the titanium substrate.

[0034] (2) Carry out secondary oxidation under the above conditions, rinse with deionized water to remove residual electrolyte on the surface, air-dry and calcinate in a muffle furnace at 400°C to obtain nanotubes with an inner diameter of 20nm, a wall thickness of 50nm, and a distance between the tubes 10nm, independent ...

Embodiment 2

[0038] The preparation method of polyethylene dioxythiophene nanotube array, comprises the steps:

[0039] (1) High-purity (above 99.5%) titanium sheets or titanium screens are pretreated (ultrasonic cleaning and drying in acetone, ethanol and distilled water, respectively) as anodes, and high-purity (above 99.5%) graphite rods are used as cathodes. Using 1,3 dimethylimidazolium trifluoroacetate and water as the electrolyte, the mass ratio of water is 10%, anodized at 100V voltage, after 0.5h of reaction, rinse with deionized water to remove the residual electrolyte on the surface, Remove the oxide film on the titanium substrate with scotch tape.

[0040] (2) Carry out secondary oxidation under the above conditions, rinse with deionized water to remove residual electrolyte on the surface, air-dry and calcinate in a muffle furnace at 600°C to obtain nanotubes with an inner diameter of 80nm, a wall thickness of 20nm, and a distance between the tubes 30nm, independently isolated...

Embodiment 3

[0044] The preparation method of polyethylene dioxythiophene nanotube array, comprises the steps:

[0045] (1) High-purity (above 99.5%) titanium sheets or titanium screens are pretreated (ultrasonic cleaning and drying in acetone, ethanol and distilled water, respectively) as anodes, and high-purity (above 99.5%) graphite rods are used as cathodes. Use N-butylpyridine trifluoromethanesulfonate and water as the electrolyte, the mass ratio of water is 7.5%, anodize at 60V voltage, after reacting for 1h, rinse with deionized water to remove the residual electrolyte on the surface, use a transparent Tape to remove the oxide film on the titanium substrate.

[0046] (2) Perform secondary oxidation under the above conditions, rinse with deionized water to remove residual electrolyte on the surface, air-dry and calcinate in a muffle furnace at 500°C to obtain nanotubes with an inner diameter of 40nm, a wall thickness of 30nm, and a distance between the tubes 18nm, independently isol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com