Composite explosion-proof plate resisting high-speed fragments and high-strength explosion impact and manufacturing method

An explosive impact, high-strength technology, applied in chemical instruments and methods, blasting, protective clothing, etc., can solve the problems of short usability, inconvenient disassembly and transportation, secondary damage, etc., to achieve strong impact performance and easy production. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

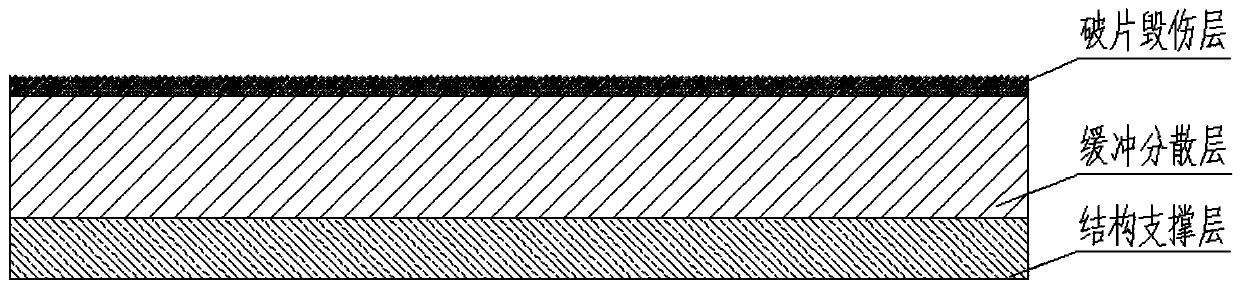

[0028] Example: A composite explosion-proof board and its manufacturing method

[0029] The composite explosion-proof board formed by the invention has a length of 1050mm, a width of 750mm and a thickness of 35mm. The specific preparation process is as follows:

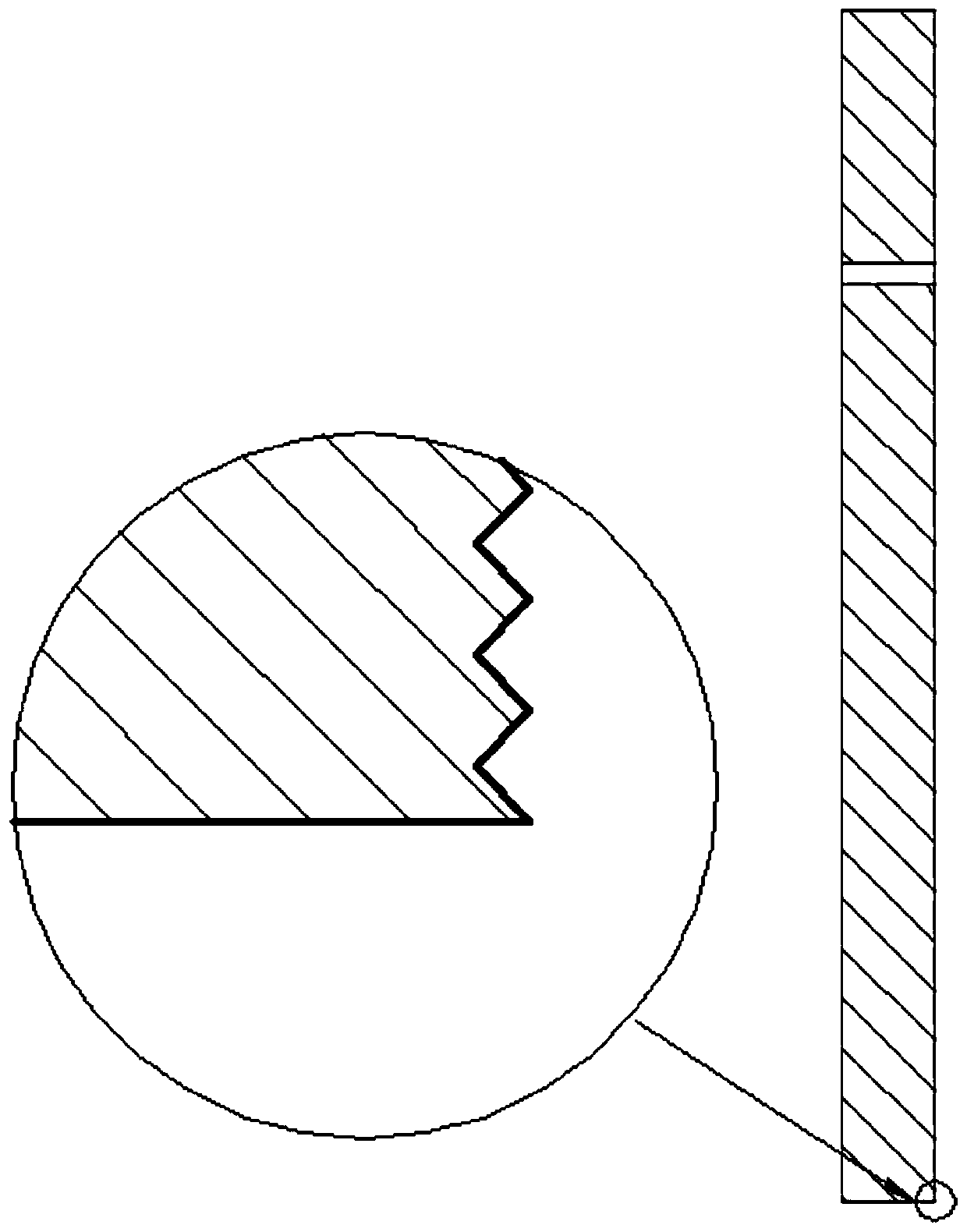

[0030] The first step is to pass the high-strength structural steel sheet through a planer, and process a sharp-angle structure damaged by fragments on one side;

[0031] In the second step, the surface of the ultra-high molecular polyethylene is frosted.

[0032] The third step is to weave the high-strength fiber fabric according to the designed weaving method;

[0033] The fourth step is to make the woven fabric into prepreg;

[0034] The fifth step is to cut the prepreg cloth according to the designed layer size and method;

[0035] In the sixth step, the structural support layer is laid and formed by hot pressing. The molding temperature is 160℃, the molding pressure is 45MPa, and the heating and curing time is 6h.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com