Plant-derived polypropylene master batch and preparation method thereof

A plant-sourced polypropylene technology, applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyolefin artificial filaments, etc., can solve the problems of reduced flame-retardant performance, poor uniformity of polypropylene masterbatch, and large coefficient of variation of breaking strength. , to achieve excellent flame retardant performance and good anti-pilling and fuzzing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

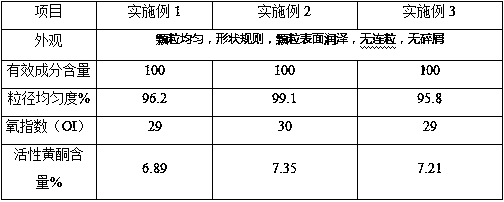

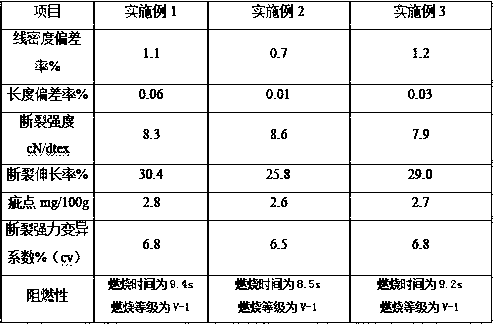

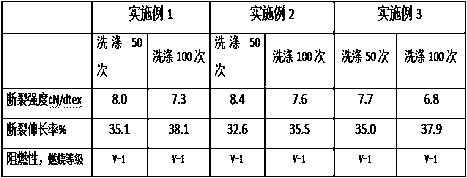

Embodiment 1

[0054] Example 1 A preparation method of honeysuckle plant source polypropylene masterbatch

[0055] Step 1, preparation of modified honeysuckle powder

[0056] (1) Selection of raw materials

[0057] Honeysuckle powder is selected as the plant source raw material of this embodiment, and 100% of the honeysuckle powder passes through a 10,000 mesh sieve, the appearance powder is loose and has no agglomeration, and the color: has the inherent color of the product, and is uniform; the smell is uniform The content of active ingredients is ≥98%, the content of chlorogenic acid is 16.5%, the moisture content is ≤5%, the total number of colonies is less than 100cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 18 months.

[0058] (2) Preparation of modified honeysuckle powder

[0059] Mix 50 parts of honeysuckle powder with 15 parts of chitin and 4 parts of starch, adjust the pH to 7.1 with sodium carbonate, add 50 parts of deionized water and heat to...

Embodiment 2

[0082] Embodiment 2 A kind of preparation method of honeysuckle plant source polypropylene fiber masterbatch

[0083] Step 1, preparation of modified honeysuckle powder

[0084] (1) Selection of raw materials

[0085] Honeysuckle powder is selected as the plant source raw material of this embodiment, and 100% of the honeysuckle powder passes through a 10,000 mesh sieve, the appearance powder is loose and has no agglomeration, and the color: has the inherent color of the product, and is uniform; the smell is uniform The content of active ingredients is ≥98%, the content of chlorogenic acid is 16.5%, the moisture content is ≤5%, the total number of colonies is less than 100cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 18 months.

[0086] (2) Preparation of modified honeysuckle powder

[0087] Mix 50 parts of honeysuckle powder with 16 parts of chitin and 5 parts of starch, adjust the pH to 7.5 with sodium carbonate, add 60 parts of deionized ...

Embodiment 3

[0110] Embodiment 3 A kind of preparation method of honeysuckle plant source polypropylene fiber masterbatch

[0111] Step 1, preparation of modified honeysuckle powder

[0112] (1) Selection of raw materials

[0113] Honeysuckle powder is selected as the plant source raw material of this embodiment, and 100% of the honeysuckle powder passes through a 10,000 mesh sieve, the appearance powder is loose and has no agglomeration, and the color: has the inherent color of the product, and is uniform; the smell is uniform The content of active ingredients is ≥98%, the content of chlorogenic acid is 16.5%, the moisture content is ≤5%, the total number of colonies is less than 100cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 18 months.

[0114] (2) Preparation of modified honeysuckle powder

[0115] Mix 50 parts of honeysuckle powder with 20 parts of chitin and 6 parts of starch, adjust the pH to 8 with sodium carbonate, add 70 parts of deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com