Nanometer adjuvant and preparation method for same

A kind of adjuvant, nano technology, applied in the field of nano adjuvant and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

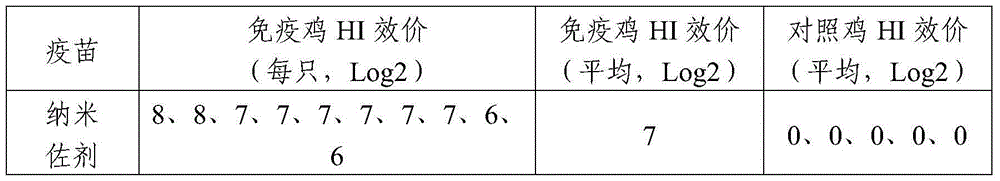

[0042] The preparation of embodiment 1 nano bird flu vaccine

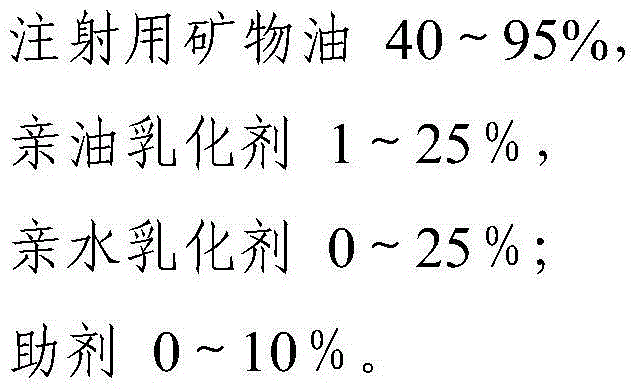

[0043]The components weighed are as follows: mineral oil for injection MARCOL52 is 95%, lipophilic emulsifier sucrose fatty acid ester is 3%, sorbitan monooleate is 1%; hydrophilic emulsifier polyoxyethylene sorbitan monooleate 0.5% ester, 0.5% polyoxyethylene (20) oleyl ether.

[0044] The nano adjuvant was prepared according to the above nano adjuvant production process, after being sterilized at 121°C for 30 minutes and cooled, 1000ml was added to the emulsification tank of the shearing machine. According to the standard, 300ml of chicken embryo inactivated avian influenza antigen H5N1 (Re-6) was slowly added into the emulsification tank, sheared and emulsified for 3 minutes, and then sheared and emulsified for 5 minutes under the condition of 8000 rpm to make a nano-sized avian influenza vaccine. To be detected after being marked. Physical indicator detection and animal experiments were carried out after 24 h...

Embodiment 2

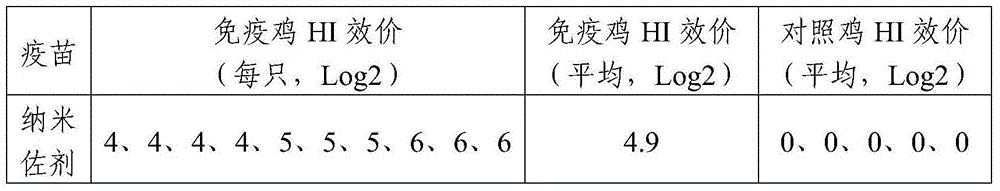

[0047] The preparation of embodiment 2 nanometer bird flu vaccines

[0048] Weigh the components as follows: 90% mineral oil MARCOL52 for injection, 0.5% lipophilic emulsifier sucrose fatty acid ester, 0.5% sorbitan monooleate; hydrophilic emulsifier polyoxyethylene (20) oleyl ether 3 %, Pluronic F68 is 1%, additives polyethylene glycol 200 is 3%, polyethylene glycol 800 is 1%, stearic acid 0.5%, palmitic acid 0.5%.

[0049] The above raw materials are made into nano-adjuvant according to the above-mentioned production process of nano-adjuvant. After sterilizing at 121°C for 30 minutes and cooling, take 1000ml and add it to the emulsification tank of the shearing machine. Slowly add 200ml of chicken Newcastle disease (ZM10 strain) inactivated antigen that meets the standards for production into the emulsification tank, shear and emulsify for 3 minutes, and then shear and emulsify for 5 minutes under the condition of 8000 rpm to make a nano-sized bird flu vaccine. Marked to be...

Embodiment 3

[0052] The preparation of embodiment 3 nano bird flu vaccines

[0053] Mineral oil for injection is Hangzhou Petrochemical injection grade white oil 40%, lipophilic emulsifier sorbitol trioleate 13%, sucrose fatty acid ester 12%; hydrophilic emulsifier polyoxyethylene (23) lauryl ether 11% , polyoxyethylene sucrose fatty acid ester is 14%, additive polyethylene glycol 400 is 6%, stearyl alcohol is 3%, and palmitic acid is 1%.

[0054] The above raw materials are made into nano-adjuvant according to the above-mentioned nano-adjuvant animal vaccine production process. After sterilizing at 121°C for 30 minutes and cooling, take 1000ml and add it to the emulsification tank of the shearing machine. At 25°C, the shear rate is 1000 rpm Slowly add 200ml antigen of chicken Newcastle disease and avian influenza double-inactivated vaccine (LaSota strain + F strain) that meets the standards for production into the emulsification tank, shear and emulsify for 3 minutes, and then shear and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com