Tissue engineering tendon scaffold reinforcement with square meshed structure

A technology of tissue engineering and stent reinforcement, which is applied in the field of medical devices, can solve the problems of large extensibility, and achieve the effects of low axial elongation, stable structure, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

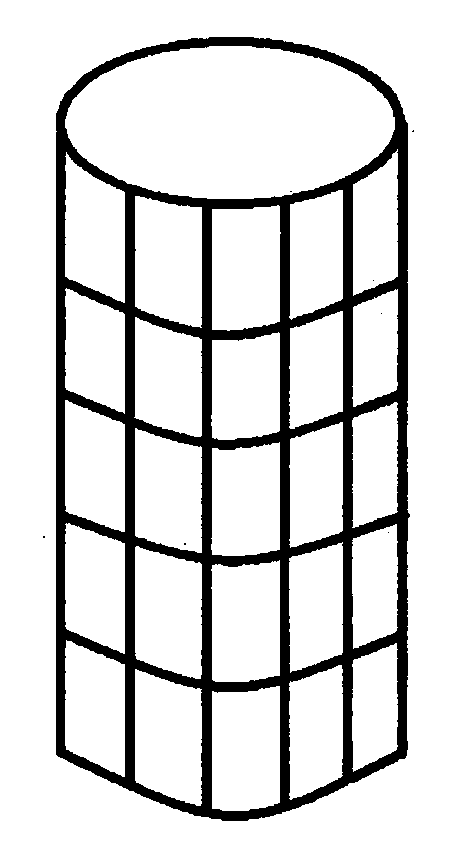

[0019] figure 1 It is a schematic diagram of the appearance structure of the tissue-engineered tendon scaffold reinforcement with a square mesh structure in this embodiment, and the preparation method of the tissue-engineered tendon scaffold reinforcement with a square mesh structure is as follows:

[0020] (1) Choose 8.78tex / 12f polyglycolic acid (Polyglatic Acid, PGA) fiber filament and 6.17tex / 24f polylactic acid (PolyLactic Acid, PLA) fiber filament, with 3 PGA fiber filaments and 2 PLA Fibrous filaments are braided on a 6-spindle braiding machine to obtain a braided wire diameter of 0.197mm.

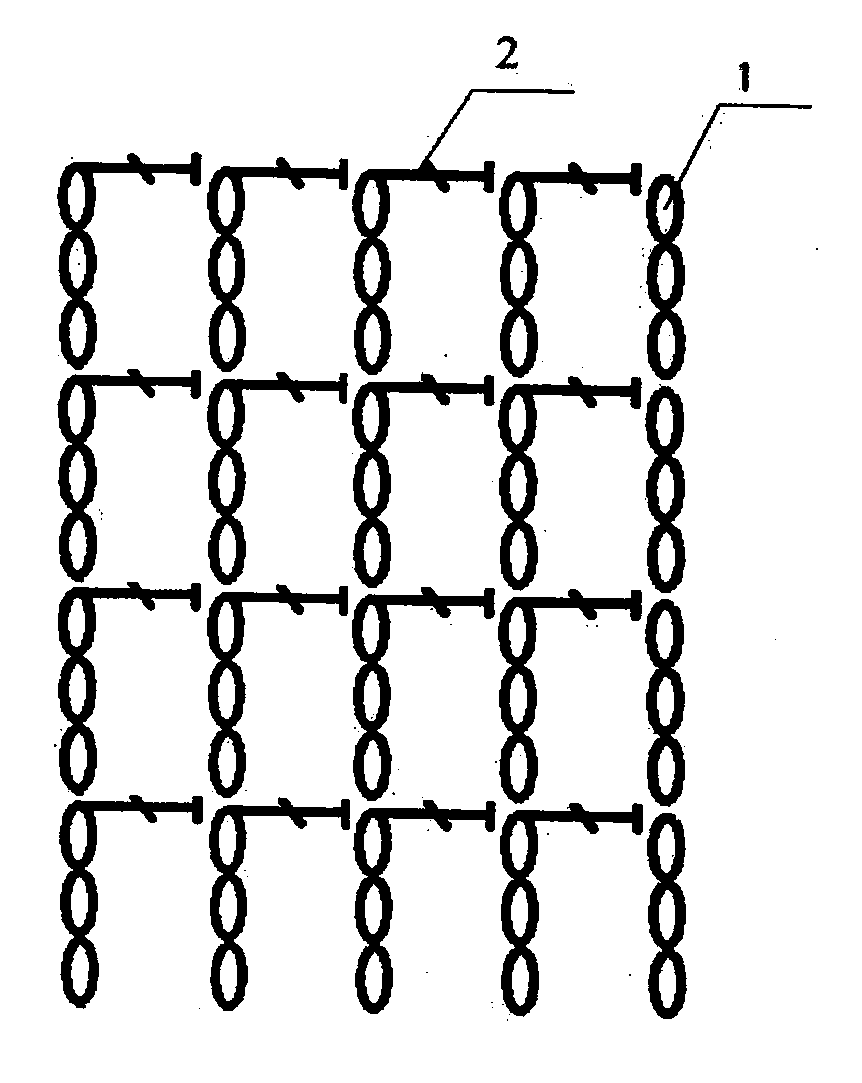

[0021] (2) Select the braided thread prepared in step (1) for use, press figure 2 The structure shown (three-needle braiding needle 1 + one long needle 2) is hand-knitted to form a rectangular grid mesh structure, and braiding needle 1 and long needle 2 form the two sides of the rectangular grid mesh, and each rectangular grid mesh The hole loops are connected to make image 3 T...

Embodiment 2

[0027] The preparation method of the tissue engineering tendon scaffold reinforcement with square mesh structure is as follows:

[0028] (1) Choose 8.78tex / 12f polyglycolic acid (Polyglatic Acid, PGA) fiber filament and 6.17tex / 24f polylactic acid (PolyLactic Acid, PLA) fiber filament, with 2 PGA fiber filaments and 1 PLA Fibrous filaments are braided on a 3-spindle braiding machine to obtain a braided wire diameter of 0.155mm.

[0029] (2) Select the braided thread prepared in step (1) for use, press figure 2 The structure shown (three-needle braiding needle 1 + one long needle 2) is hand-knitted to form a rectangular grid mesh structure, and braiding needle 1 and long needle 2 form the two sides of the rectangular grid mesh, and each rectangular grid mesh The hole loops are connected to make image 3 The shown circular cylindrical hollow ring structure has 6 rectangular grid holes, an inner diameter of 8.5 mm, a thickness of 0.9 mm, and a length of 30 mm.

[0030] Throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com