A rapid method for preparing silica/wood composites

A technology of silica and composite materials, which is applied in the direction of wood impregnation, wood impregnation, wood processing appliances, etc., can solve the problems of long production process, high cost, insufficient uniformity of composite, etc., and achieves reduction of production process time, stable quality, Compound uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

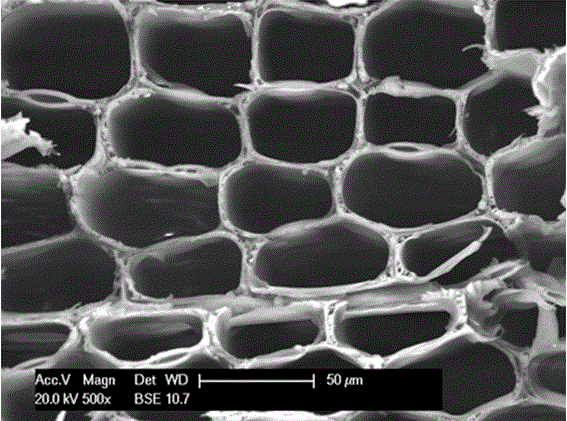

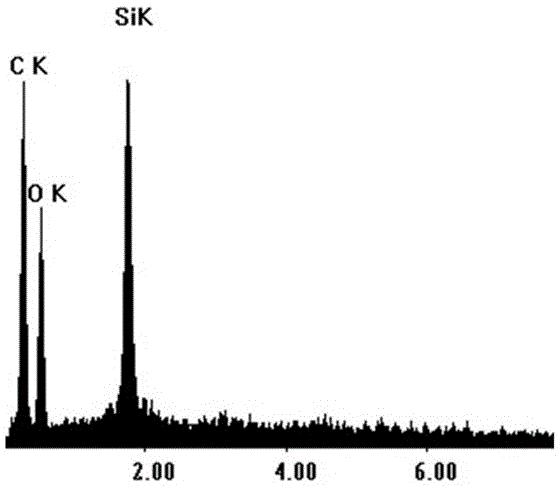

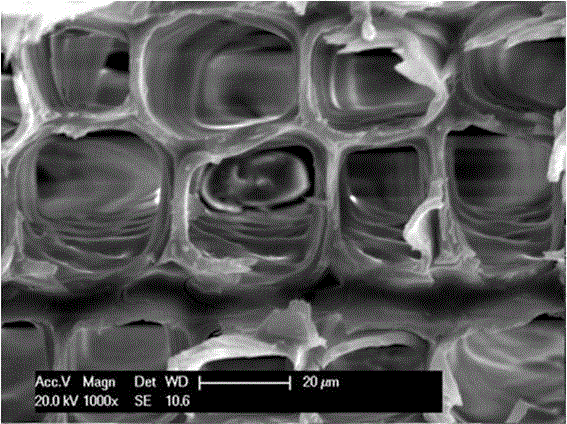

Image

Examples

Embodiment 1

[0030] The method for rapid preparation of silica / wood composites is as follows:

[0031] 1. Wood pretreatment: After the log is peeled and cut, put it in a container and add water to preheat and cook for 24 hours, then put it into a drying box, adjust the drying temperature to 103°C, and the drying time to 18 hours for pre-drying treatment.

[0032] 2. The configuration of the silicon-containing precursor solution: tetraethyl orthosilicate is used as the precursor, and anhydrous ethanol is used as the solvent to mix uniformly to obtain a mixed solution, and concentrated hydrochloric acid is added as a catalyst, wherein the amount of ethyl orthosilicate and deionized water is equal to Ratio 1:2, tetraethyl orthosilicate and absolute ethanol are uniformly mixed according to the ratio of substance amount of 1:2, and concentrated hydrochloric acid is added dropwise while magnetic stirring to make the pH value of the whole solution 2.5. Keep magnetic stirring for 30 min until the ...

Embodiment 2

[0037] The method for rapid preparation of silica / wood composites is as follows:

[0038] 1. Wood pretreatment: After the log is peeled and cut, put it in a container and add water to preheat and cook for 24 hours, then put it into a drying box, adjust the drying temperature to 103°C, and the drying time to 18 hours for pre-drying treatment.

[0039] 2. The configuration of the silicon-containing precursor solution: tetraethyl orthosilicate is used as the precursor, and anhydrous ethanol is used as the solvent to mix uniformly to obtain a mixed solution, and concentrated hydrochloric acid is added as a catalyst, wherein the amount of ethyl orthosilicate and deionized water is equal to Ratio 1:2, tetraethyl orthosilicate and absolute ethanol are uniformly mixed according to the ratio of substance amount of 1:2, and concentrated hydrochloric acid is added dropwise while magnetic stirring to make the pH value of the whole solution 2.5. Keep magnetic stirring for 30 min until the ...

Embodiment 3

[0044] The method for rapid preparation of silica / wood composites is as follows:

[0045] 1. Wood pretreatment: After the log is peeled and cut, put it in a container and add water to preheat and cook for 24 hours, then put it into a drying box, adjust the drying temperature to 103°C, and the drying time to 18 hours for pre-drying treatment.

[0046] 2. The configuration of the silicon-containing precursor solution: tetraethyl orthosilicate is used as the precursor, and anhydrous ethanol is used as the solvent to mix uniformly to obtain a mixed solution, and concentrated hydrochloric acid is added as a catalyst, wherein the amount of ethyl orthosilicate and deionized water is equal to Ratio 1:2, tetraethyl orthosilicate and absolute ethanol are uniformly mixed according to the ratio of substance amount of 1:2, and concentrated hydrochloric acid is added dropwise while magnetic stirring to make the pH value of the whole solution 2.5. Keep magnetic stirring for 30 min until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com