A kind of low-cost environment-friendly polyester film for kink packaging and preparation method thereof

A polyester film and environment-friendly technology, applied in the field of polyester film, can solve the problems of high cost and unenvironmental protection of kinked packaging films, and achieve the effects of reducing production costs, improving kinking, and maintaining hygiene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

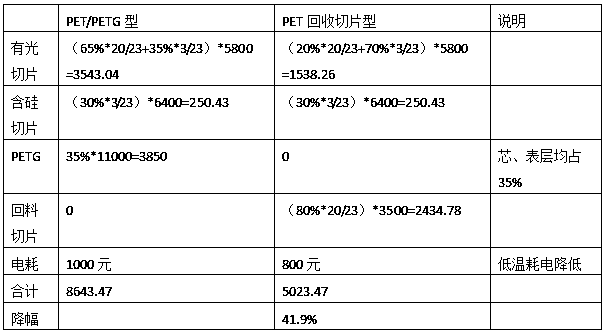

[0032] Embodiment 1. A low-cost, environment-friendly polyester film for twisted packaging with a thickness of 23 microns is prepared using three-layer co-extruded biaxially stretched production equipment at a production speed of 200 m / min. It consists of upper and lower surface layers and a core layer.

[0033] The thickness of the core layer is 20um, 20% bright polyester chips, 80% recycled polyester chips, the thickness of both surface layers is 1.5um, 70% bright polyester chips, 30% silicon-containing polyester chips ( Silica concentration 3000ppm, particle size 3.9um).

[0034] The production process of this example mainly includes the following steps:

[0035] A. Preparation of the core layer: Fluidize the core layer polyester chips with a good ratio through a fluidized bed at a temperature of 170°C for 15-20min into a drying tower, and dry them at a temperature of 160°C for 4-5 hours in the drying tower to obtain Dry raw materials; the dry raw materials are heated into...

Embodiment 2

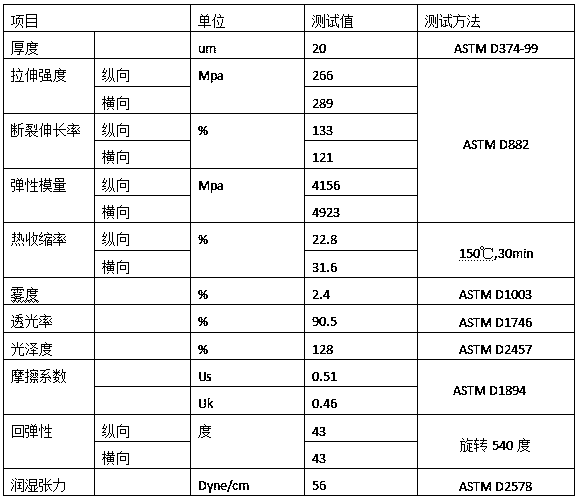

[0049] Embodiment 2, a low-cost environmentally friendly polyester film for twisted packaging with a thickness of 20 microns is prepared by three-layer co-extruded biaxially stretched production equipment, and the production speed is 230m / min. It consists of upper and lower surface layers and a core layer.

[0050] The thickness of the core layer is 17um, 25% bright polyester chips, 75% recycled chips; the thickness of the two surface layers is 1.5um, 70% bright polyester chips, 30% silicon-containing polyester chips (dioxide Silicon concentration 3000ppm, particle size 3.9um).

[0051] The production process of this example mainly includes the following steps:

[0052] A. Preparation of the core layer: Fluidize the well-proportioned core layer raw materials through a fluidized bed at a temperature of 170°C for 15-20 minutes into a drying tower, and dry them in a drying tower at a temperature of 160°C for 4-5 hours to obtain dried raw materials The dry raw material is heated ...

Embodiment 3

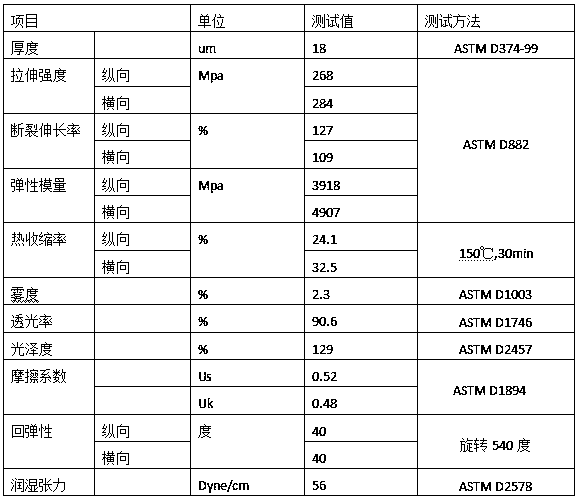

[0066] Example 3: A low-cost, environment-friendly polyester film for twisted packaging with a thickness of 18 microns is prepared using three-layer co-extruded biaxially stretched production equipment at a production speed of 250 m / min. It consists of upper and lower surface layers and a core layer.

[0067] The thickness of the core layer is 15um, 30% bright slices, 70% recycled slices; the thickness of the two surface layers is 1.5um, 70% bright polyester slices, 30% silicon-containing polyester slices (silicon dioxide concentration 3000ppm, particle size 3.9um).

[0068] The production process of this example mainly includes the following steps:

[0069] A. Preparation of the core layer: Fluidize the well-proportioned core layer raw materials through a fluidized bed at a temperature of 170°C for 15-20 minutes into a drying tower, and dry them in a drying tower at a temperature of 160°C for 4-5 hours to obtain dry raw materials The dry raw material is heated into a molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com