Energy-saving deoxidation system of industrial boiler

A technology for industrial boilers and oxygen pumps, applied in degassed water/sewage treatment, etc., can solve the problems of large flushing water consumption, limited promotion, difficult temperature control, etc., achieve high degree of automation, ensure the quality of oxygen removal, and easy temperature control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The energy-saving and oxygen-removing system for industrial boilers of the present invention is based on Henry's law, and the oxygen-free gas is strongly mixed with oxygen-containing water, so that the oxygen dissolved in the water is precipitated into the gas, so that the feed water meets the water quality requirements. The oxygen-containing gas reacts in the heating reactor to form an oxygen-free inert gas for recycling.

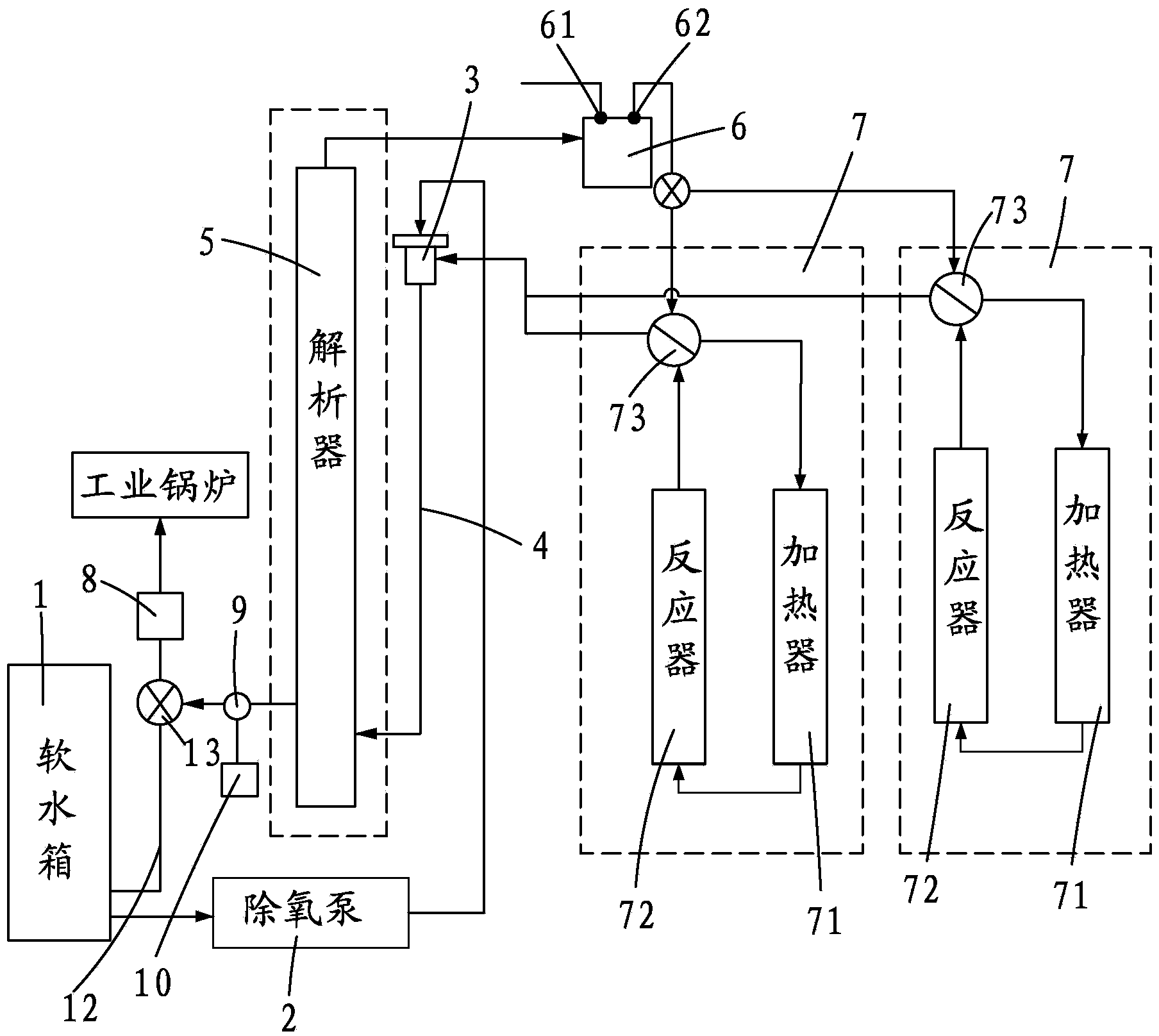

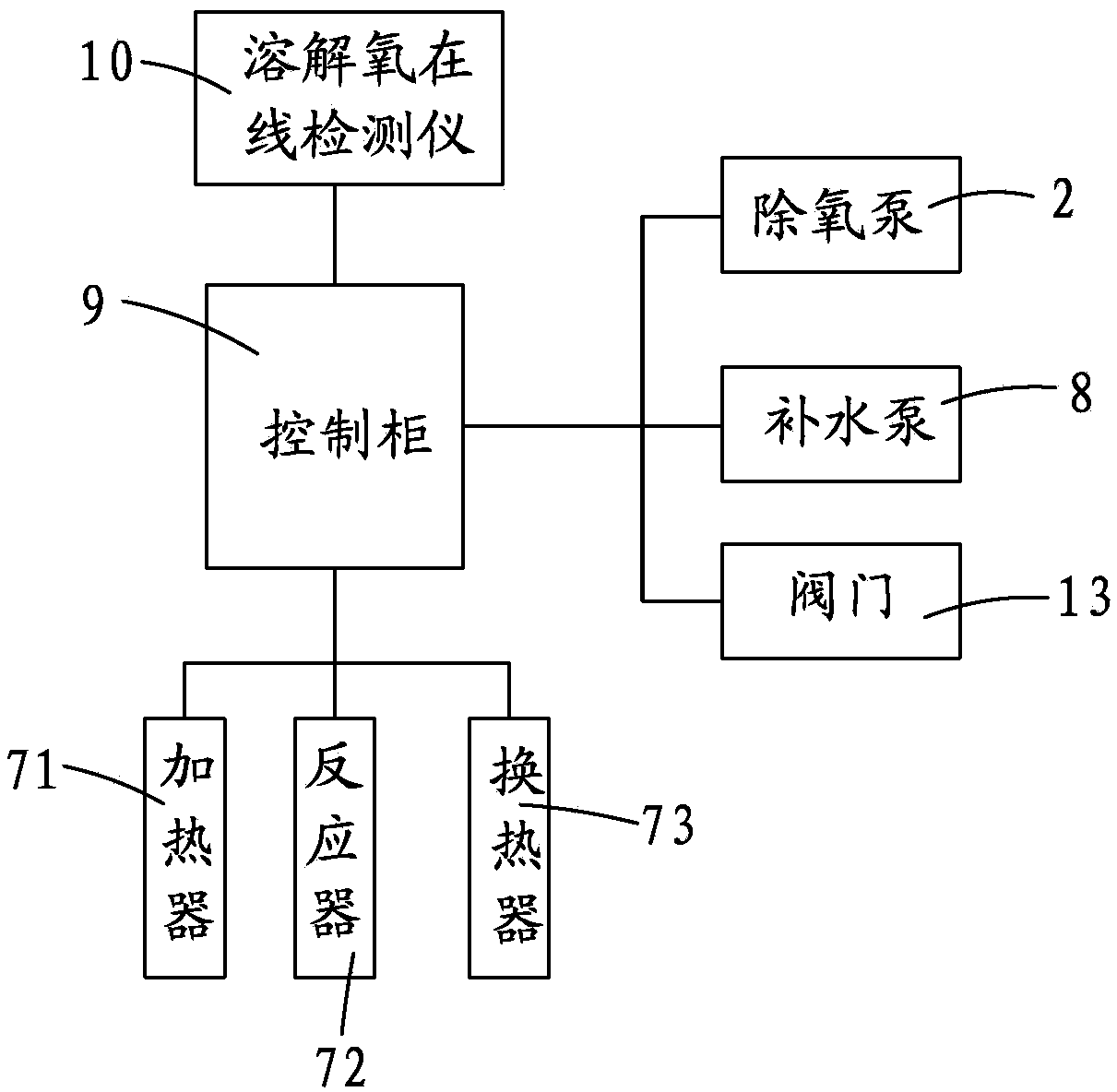

[0022] Such as figure 1 As shown, the industrial boiler energy-saving deaeration system of the present invention includes a soft water tank 1, a deaeration pump 2, an ejector 3, a mixing tube 4, a resolver 5, a gas-water separator 6 and at least two Deoxidation assembly 7; any one of said deoxidation assembly 7 includes a heater 71, a reactor 72 and a heat exchanger 73 connected end to end; The heat exchanger 73 of the deaeration pump 2 and the deaeration assembly 7 is connected to the water inlet of the ejector 3, and the water outlet of the eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com