Nuclear power station control rod drive mechanism's detachable joint and its preparation method

A driving mechanism and control rod technology, applied in the field of nuclear power, can solve problems such as uncertain supply cycle, high risk, and affecting the construction schedule of new nuclear power projects, and achieve the effect of facilitating mass production and accelerating the process of localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the embodiments described in this specification are only for explaining the present invention, not for limiting the present invention.

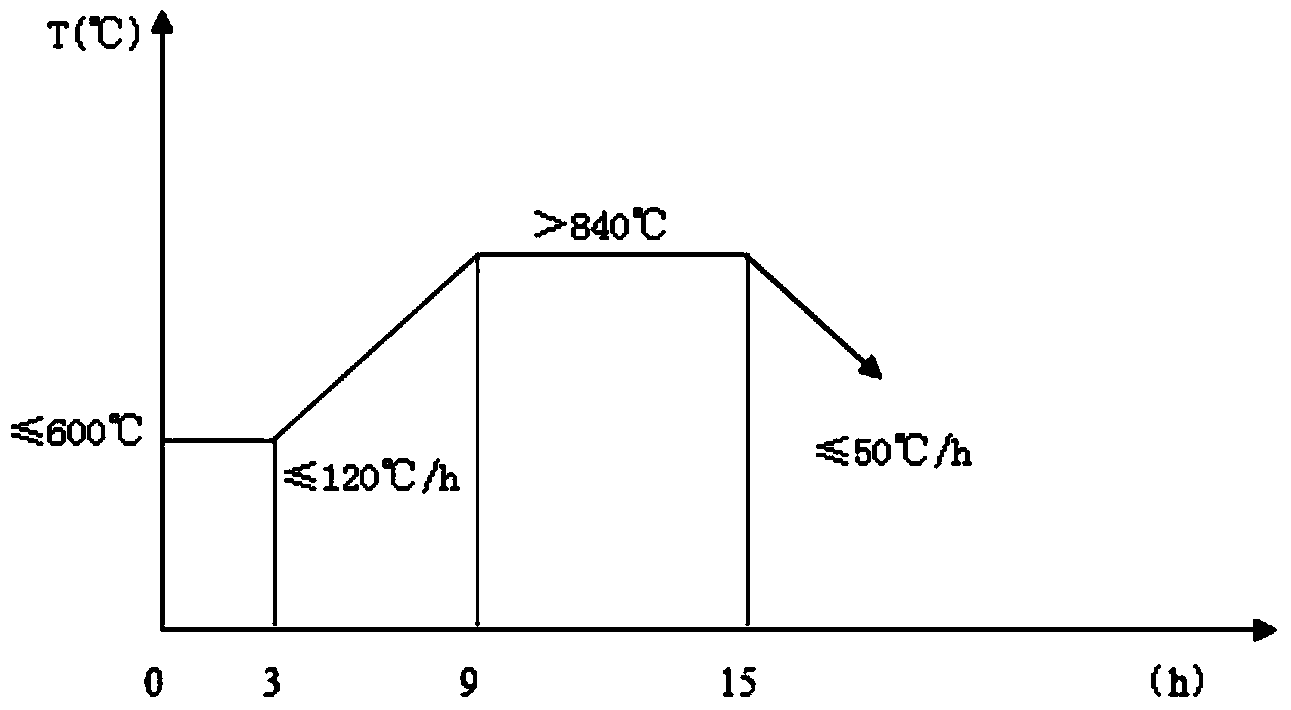

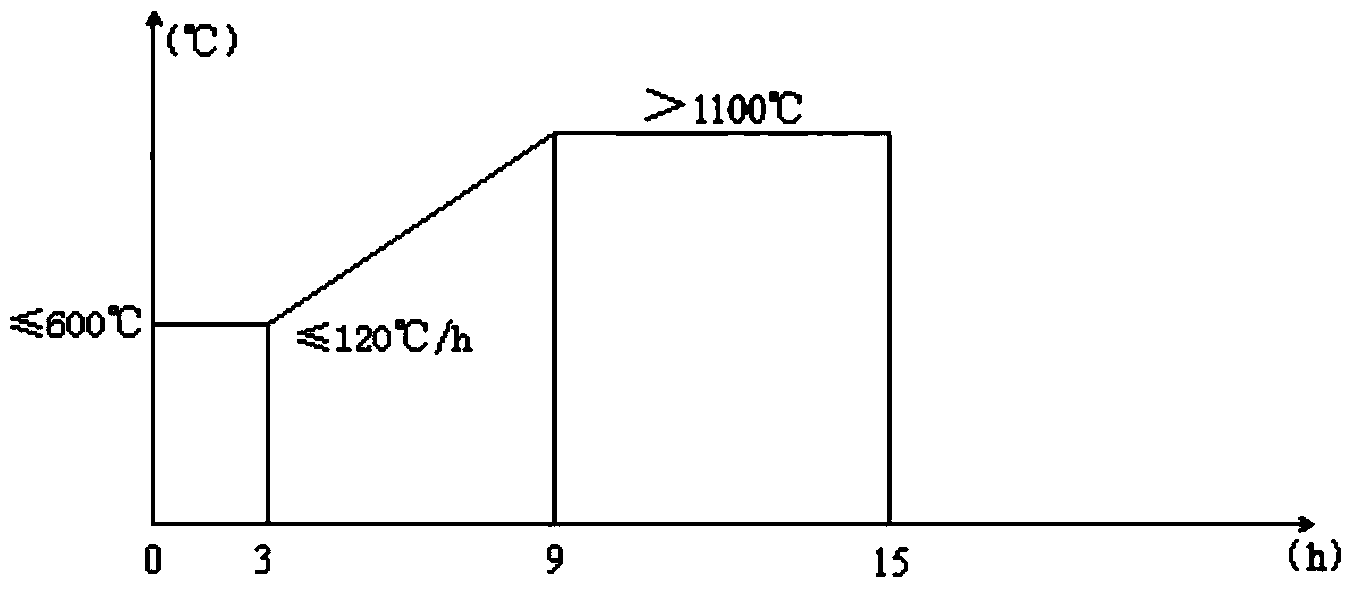

[0036] The main process of the preparation method of the detachable joint of the control rod drive mechanism of the nuclear power plant includes: vacuum smelting→casting electrodes→electroslag remelting→electroslag ingot annealing→forging billets→steel billet annealing→hot-rolled round steel→round steel quenching and tempering Heat treatment→performance testing→ultrasonic flaw detection→inspection and warehousing

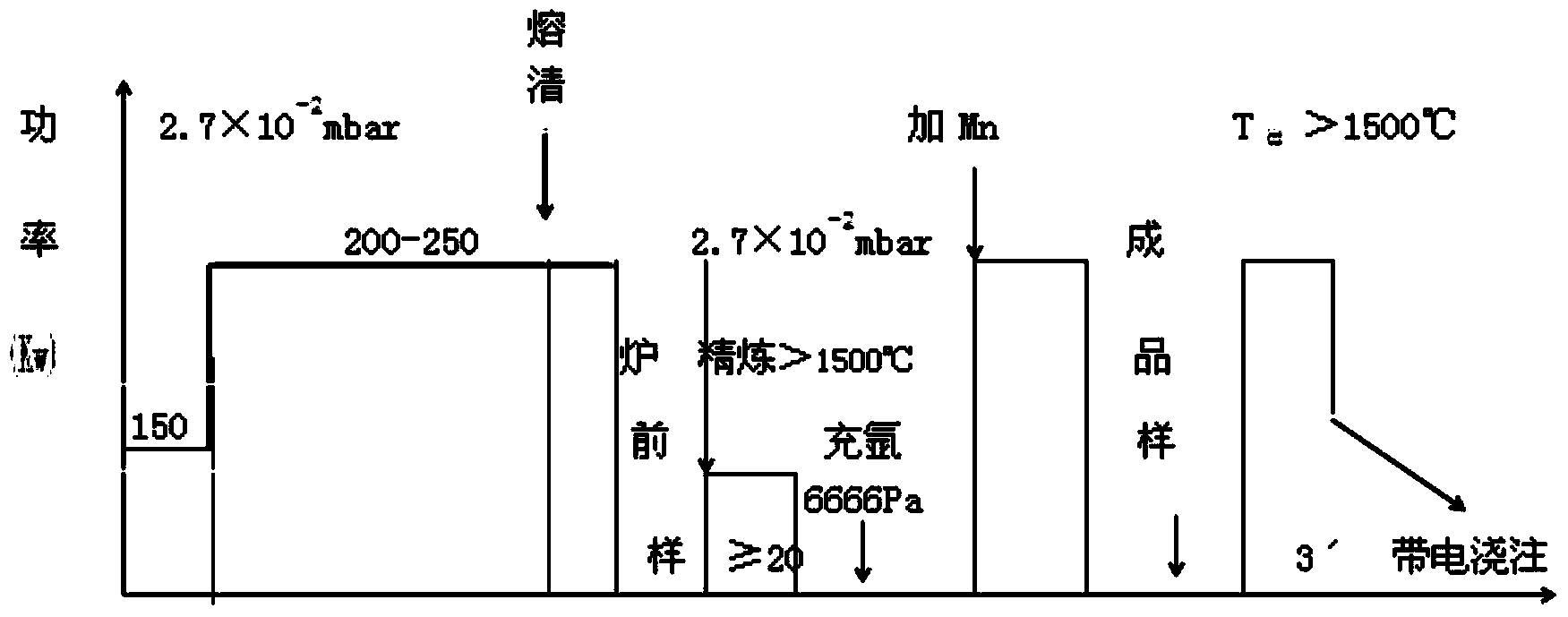

[0037] 1. Vacuum smelting

[0038] Raw materials are selected from metal chromium, metal manganese, metal nickel, metal molybdenum, pure iron, electrode carbon and crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com