Continuous excavating equipment and process for roadways

A roadway and equipment technology, which is applied in the comprehensive mechanized continuous excavation equipment and technology of rock roadways, and in the field of underground semi-coal and rock roadways, can solve the problems of low roadway excavation efficiency, improve operational safety, improve excavation efficiency, reduce The effect of worker labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings.

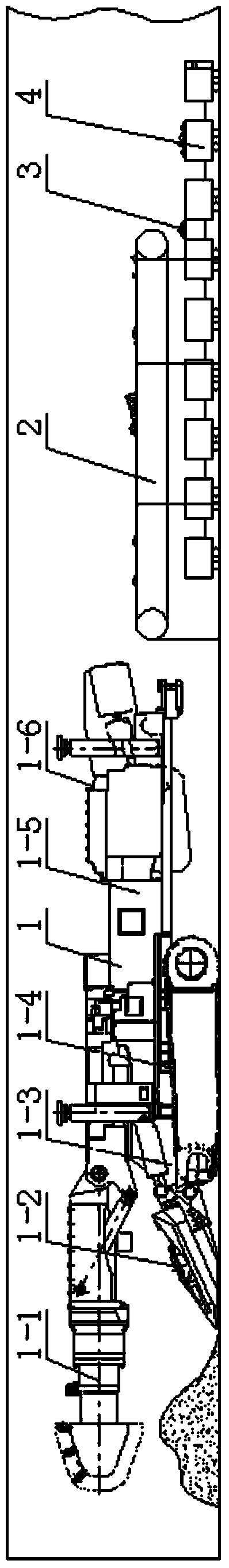

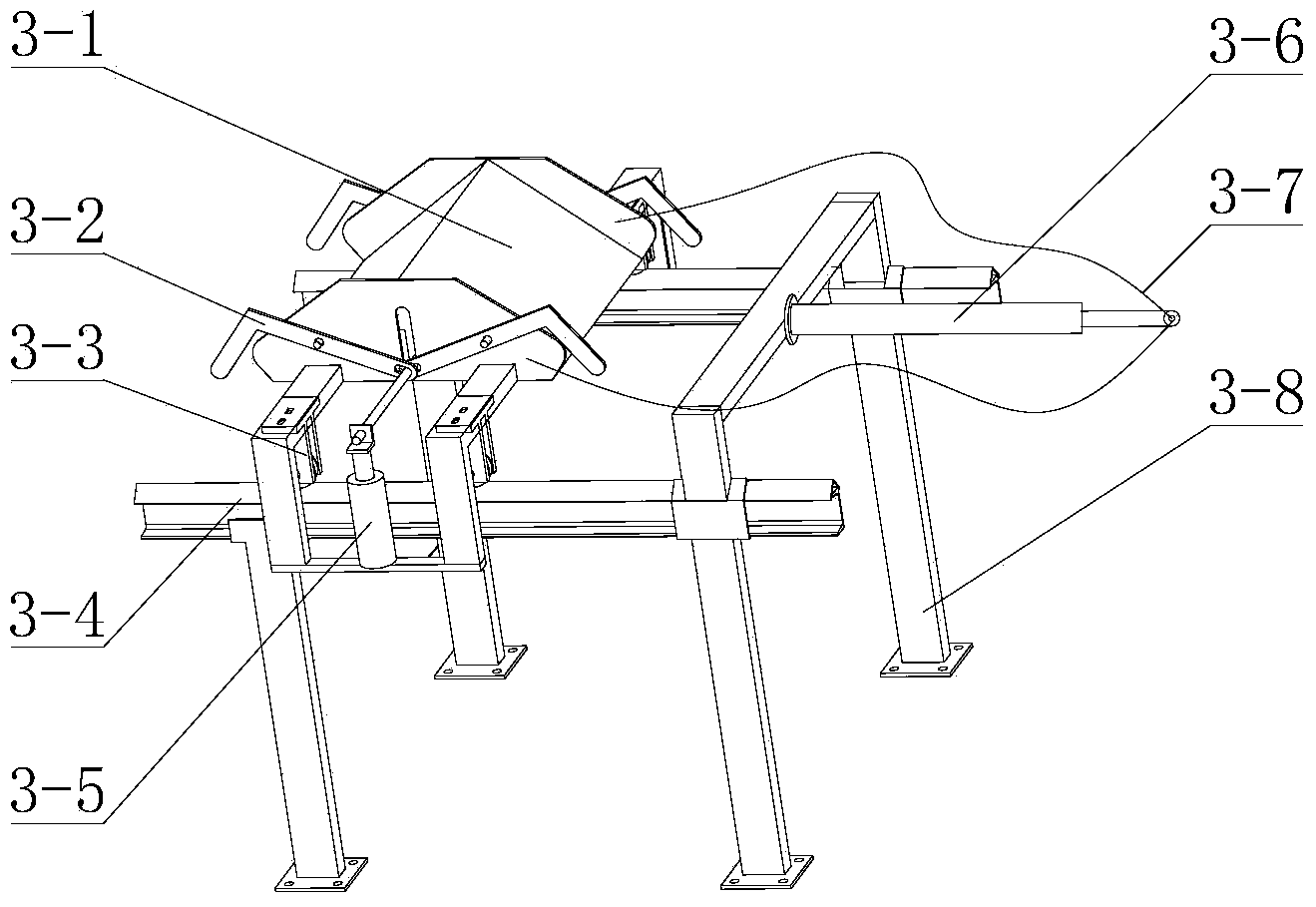

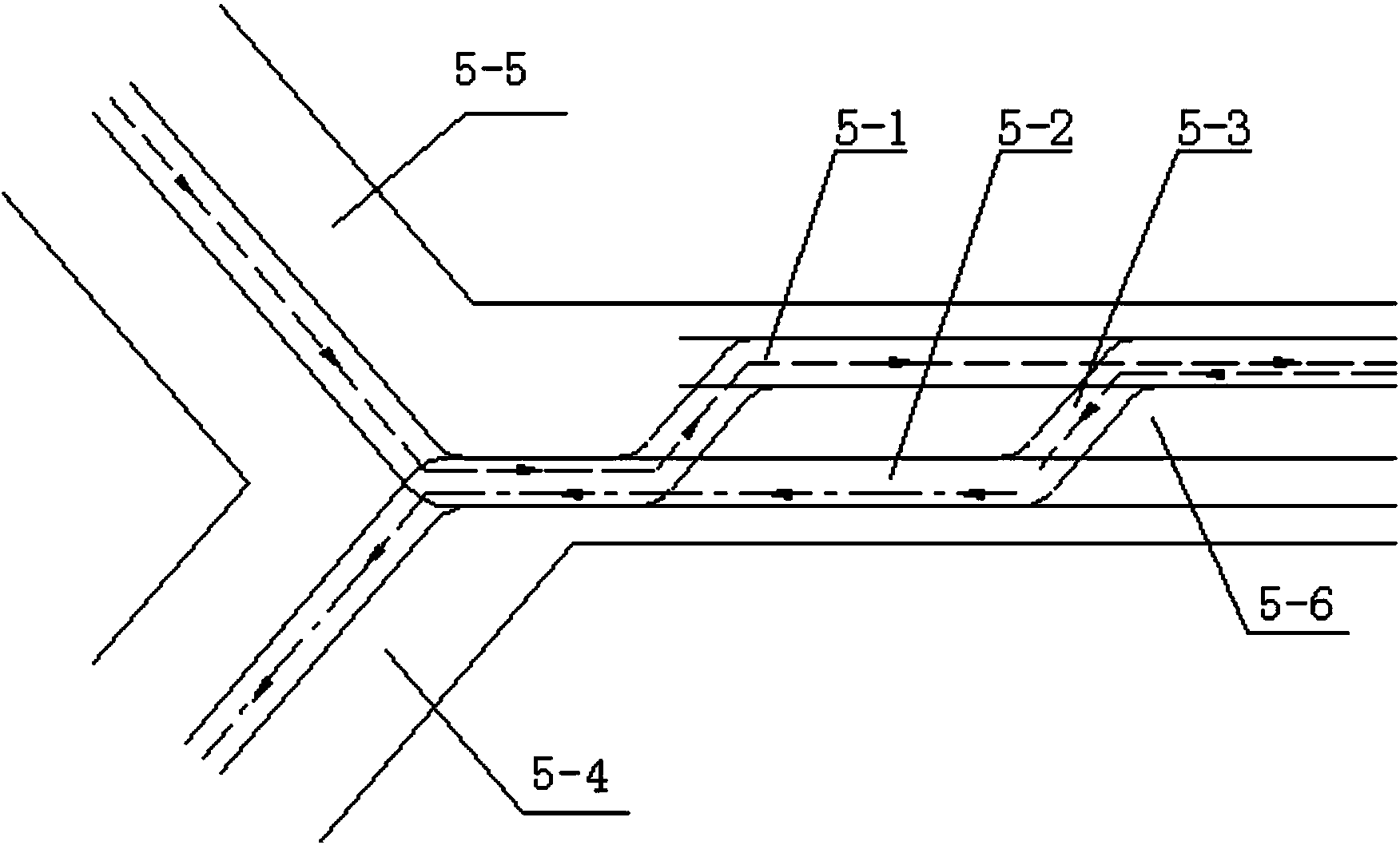

[0017] Such as figure 1 with figure 2 As shown, a continuous excavation equipment for a roadway includes a set of intelligent operation lines composed of a cantilever roadheader 1, a belt conveyor 2, a continuous loading device 3, and a mine cart 4. The cantilever type roadheader 1 includes a cutting mechanism 1-1, a loading mechanism 1-2, a transport mechanism 1-3, a crawler walking mechanism 1-4, a main frame 1-5 and an electro-hydraulic system 1-6, which will cut The mechanism 1-1 is aimed at the roadway head-on; the belt conveyor 2 is a crawler-type movable belt conveyor and is arranged at the tail of the cantilever roadheader 1; the mine cart 4 is arranged under the belt on the belt conveyor 2, and the mine There is a traction motor on the cart 4, and a mine cart track is provided under the mine cart 4. The mine cart track includes a gangue-carrying mine cart track 5-2, an unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com