Cabin cross section circumference measuring device and method based on non-contact profiling method

A non-contact, perimeter measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the accuracy of the measurement results can only reach the millimeter level, cannot meet the requirements of high-precision workpiece measurement, and cannot be measured with high-precision parts and other problems, to achieve the effect of simple measurement method, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

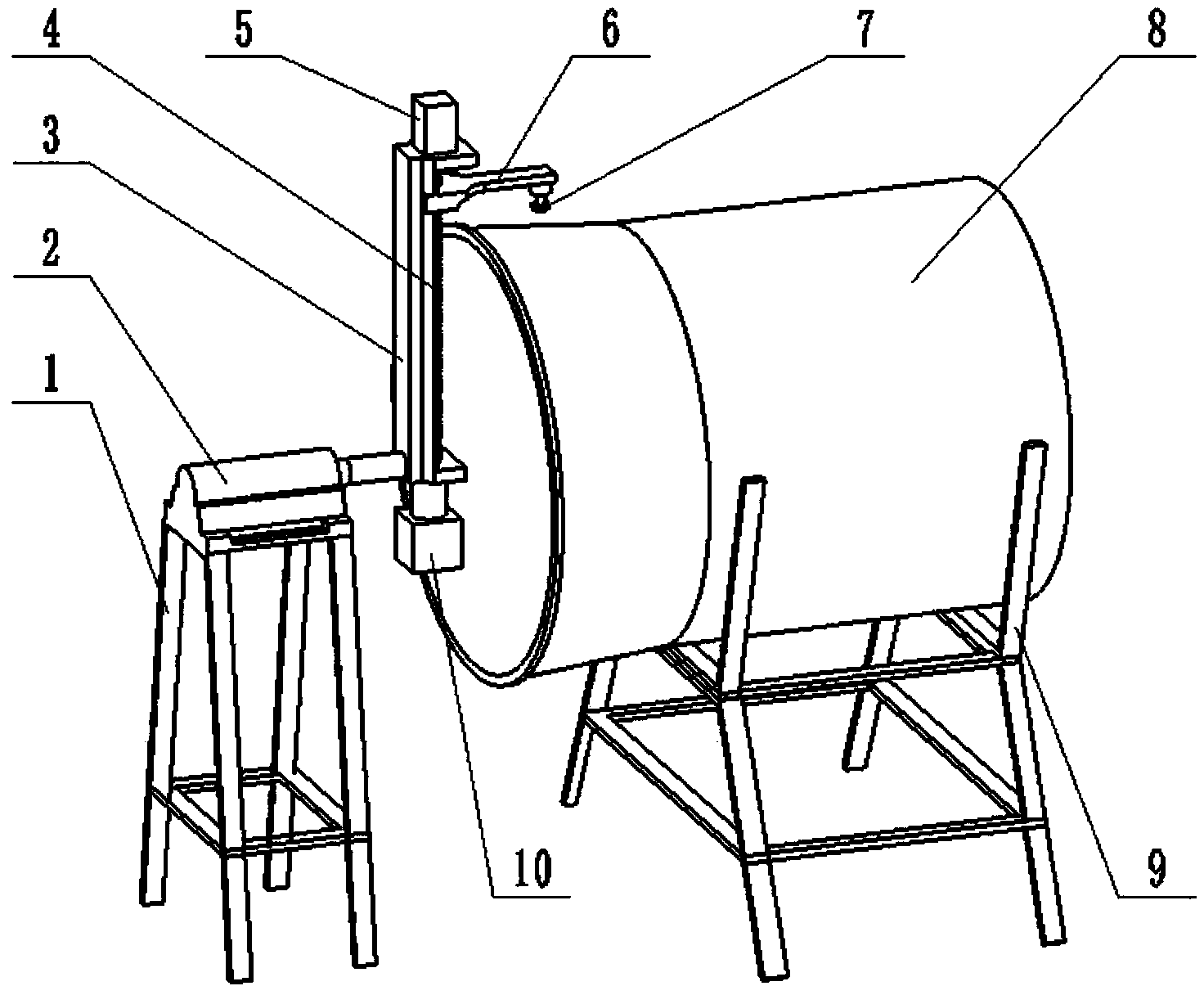

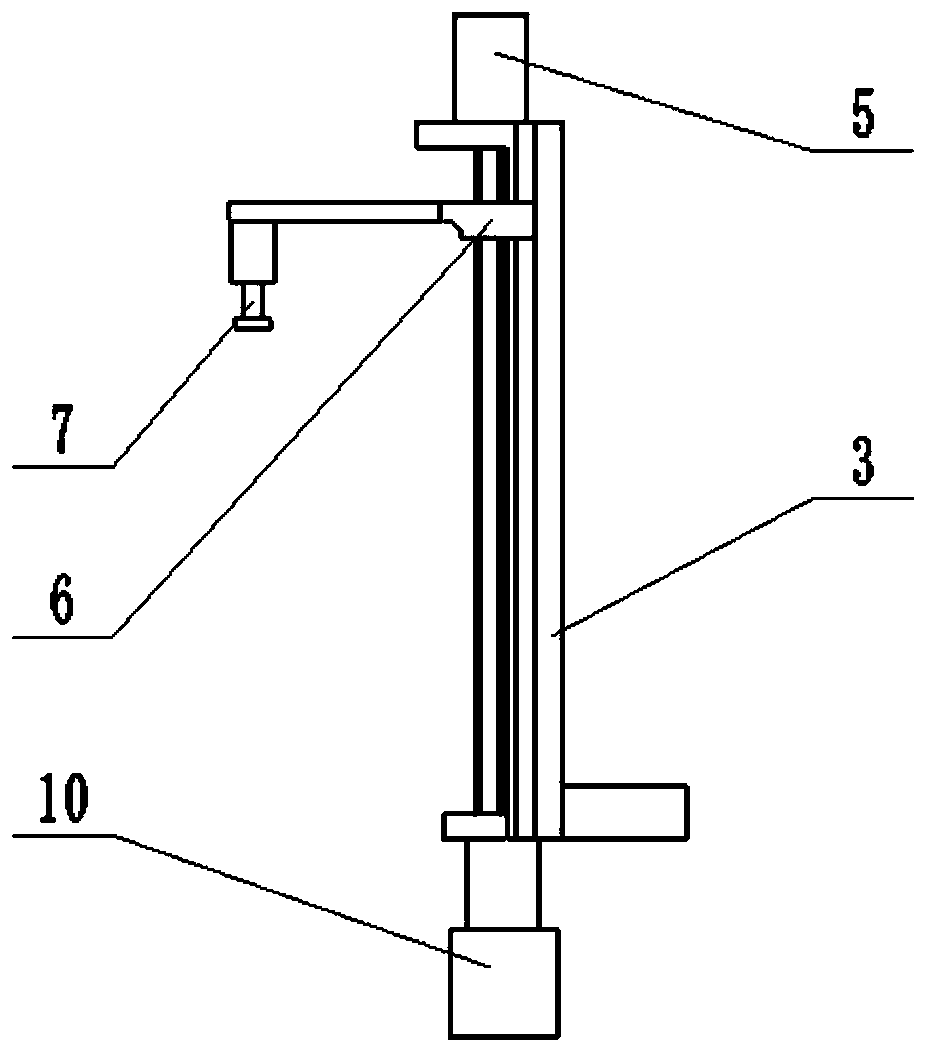

[0042] Attached below Figure 1 to Figure 7 The specific embodiment of the present invention is described further:

[0043] figure 1 It is the overall assembly diagram of the measuring device, which is divided into three parts, namely the reference coordinate motor system, the follow-up rocker system, and the UUT system.

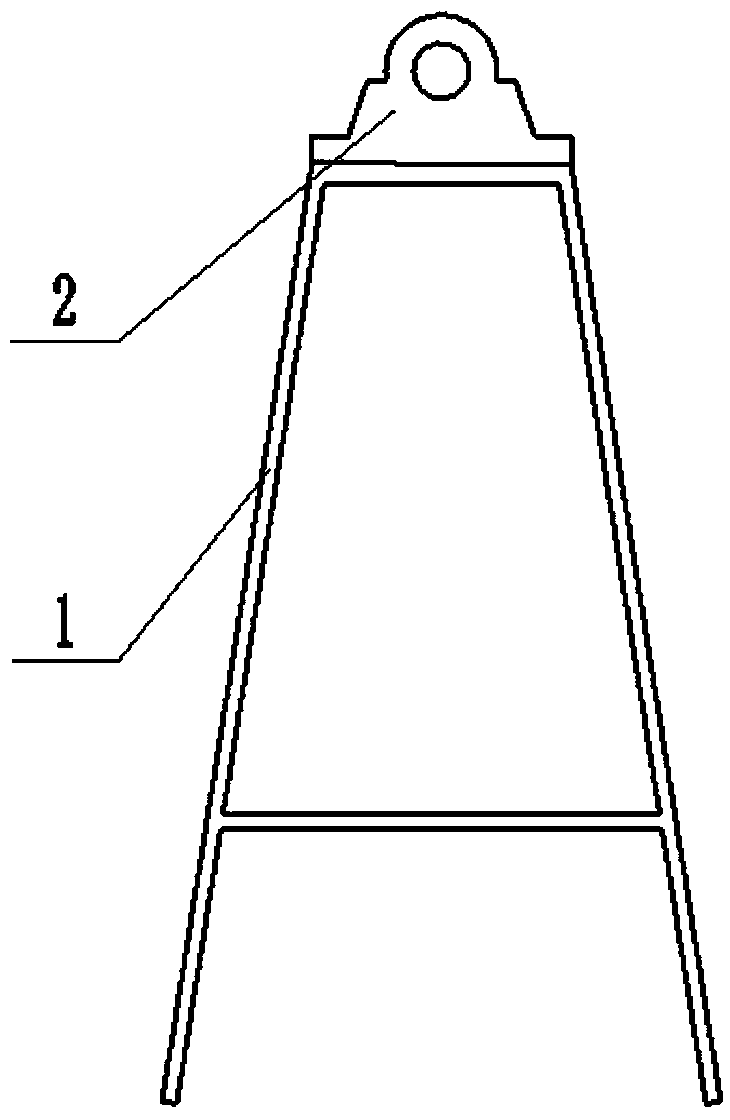

[0044] Such as figure 2 As shown, the reference coordinate motor system is composed of the reference motor 2 and the frame 1. The reference motor 2 is placed on the top of the machine base 1, and it is required to be rigidly connected with the machine base 1 to ensure that the rotation axis direction of the reference motor 2 is parallel to the upper plane of the machine base 1, and to ensure that it can be connected with the rocker arm 3 during the working process. Good interface, providing more accurate location information. When the machine base 1 is placed, ensure that its four corners are in good and reliable contact with the ground, so that the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com