Resolution detecting and calibrating method for ultrasonic microscope

A technology of ultrasonic microscope and calibration method, which is applied in the direction of material analysis, measuring device, and analysis material using sound wave/ultrasonic wave/infrasonic wave, which can solve problems such as defect detection ability, and achieve the effect of easy implementation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is described in detail below:

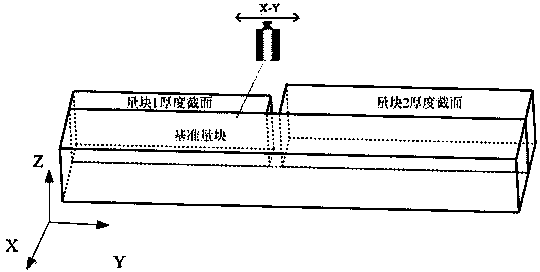

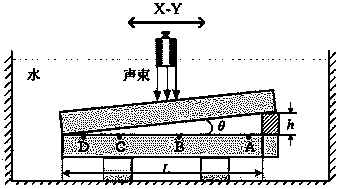

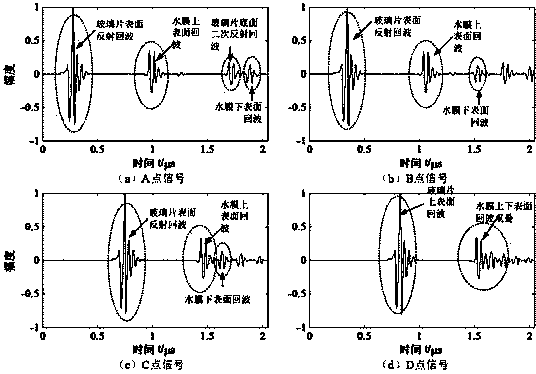

[0015] 1. If figure 1 As shown, when the ultrasonic scanning microscope is working, the computer triggers the pulse receiving / transmitting device to generate an excitation signal, which excites the piezoelectric chip to generate high-frequency ultrasonic waves. The sound wave is focused by the acoustic lens to the surface or inside of the sample to be tested, and reflection occurs at the discontinuity of the acoustic characteristics at the interface or inside of the sample. The reflected waves are picked up by piezoelectric elements and converted into electrical signals. The echo signal is sent to the data acquisition card after being amplified by the limiting and amplifying circuit, converted into a digital signal, and then digitally processed. At the same time, the computer controls the mechanical scanning platform to perform two-dimensional scanning control on the x-y horizontal plane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com