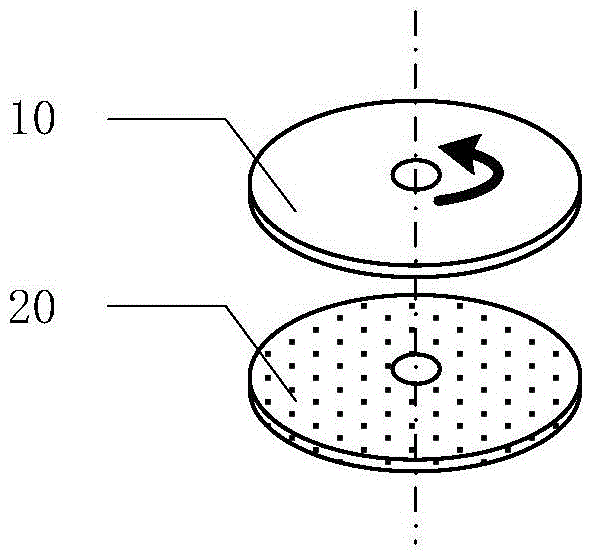

Rotary friction generator, voltage stabilized output circuit and power supply device

A technology of friction generator and regulated output, applied in the direction of friction generator, etc., can solve the problems of practical application limitation, high impedance, low output power, etc., and achieve the effect of simplifying the preparation process, reducing the cost, and improving the output current and power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

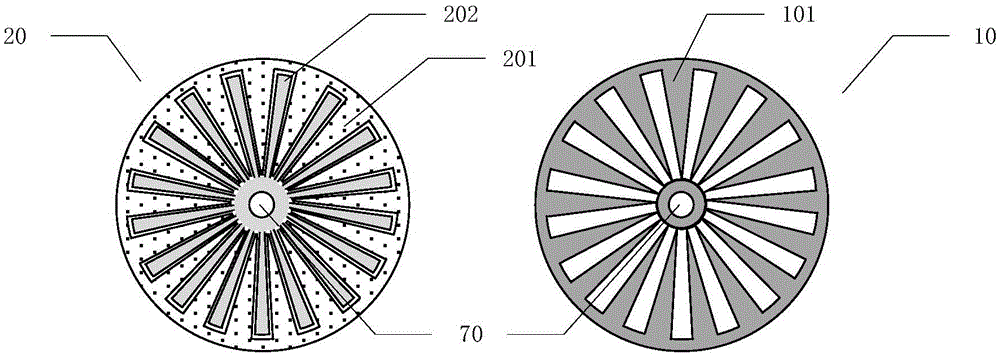

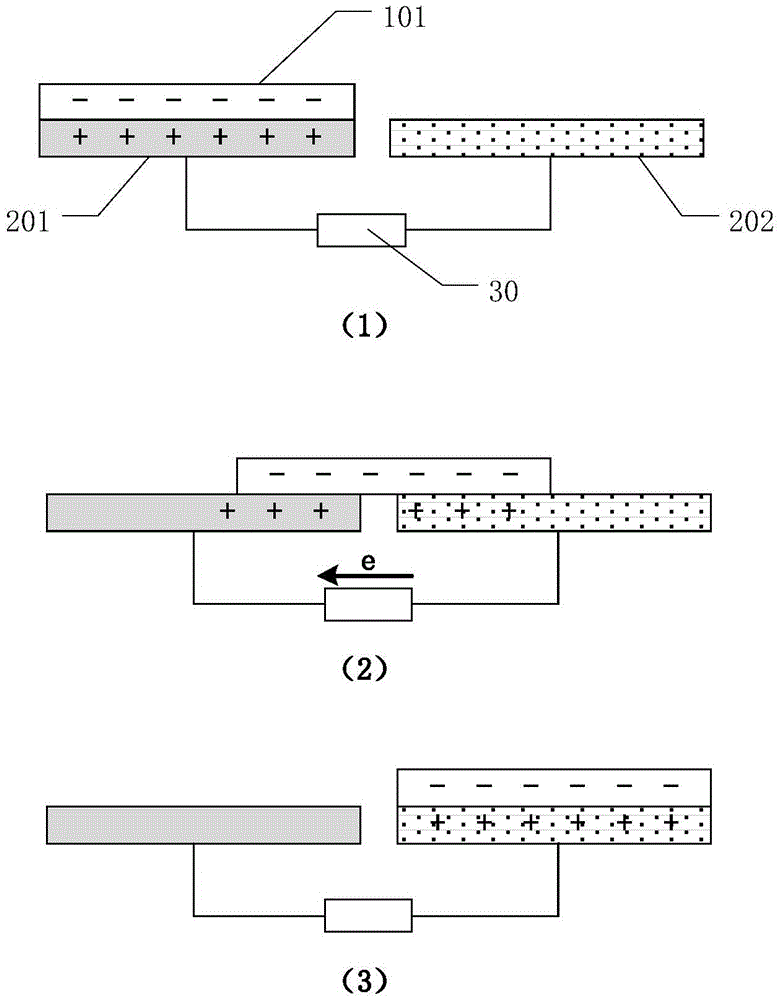

[0094] On a circular copper sheet with a central hole and a diameter of about 10 cm, 60 fan-shaped friction units arranged radially radially with the central hole as a dot are formed by cutting, and the central angle of each friction unit is about 3°. There is a fan-like gap between two adjacent friction units, and the outer edges of all fan-shaped friction units are kept connected. Take another circular acrylic plastic plate with a central hole and a diameter of about 10 cm as a supporting member, and prepare a first electrode unit with the same shape and size as the friction unit on it, and at the same time, the gap between adjacent first electrode units The second electrode unit is formed in the center, and a certain gap is maintained between the first electrode unit and the second electrode unit. All the second electrode units are connected and led out through wires, and are used as one end for outputting electrical signals to the external circuit, and the inner edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com