Middle-high-frequency transformer

A technology of high-frequency transformers and main transformers, applied in transformer/inductor cooling, transformer/inductor cores, transformer/inductor coils/windings/connections, etc. Rectifier diodes are easily damaged, transformer temperature rises and other problems, to achieve the effect of improving water cooling effect, increasing coupling degree, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

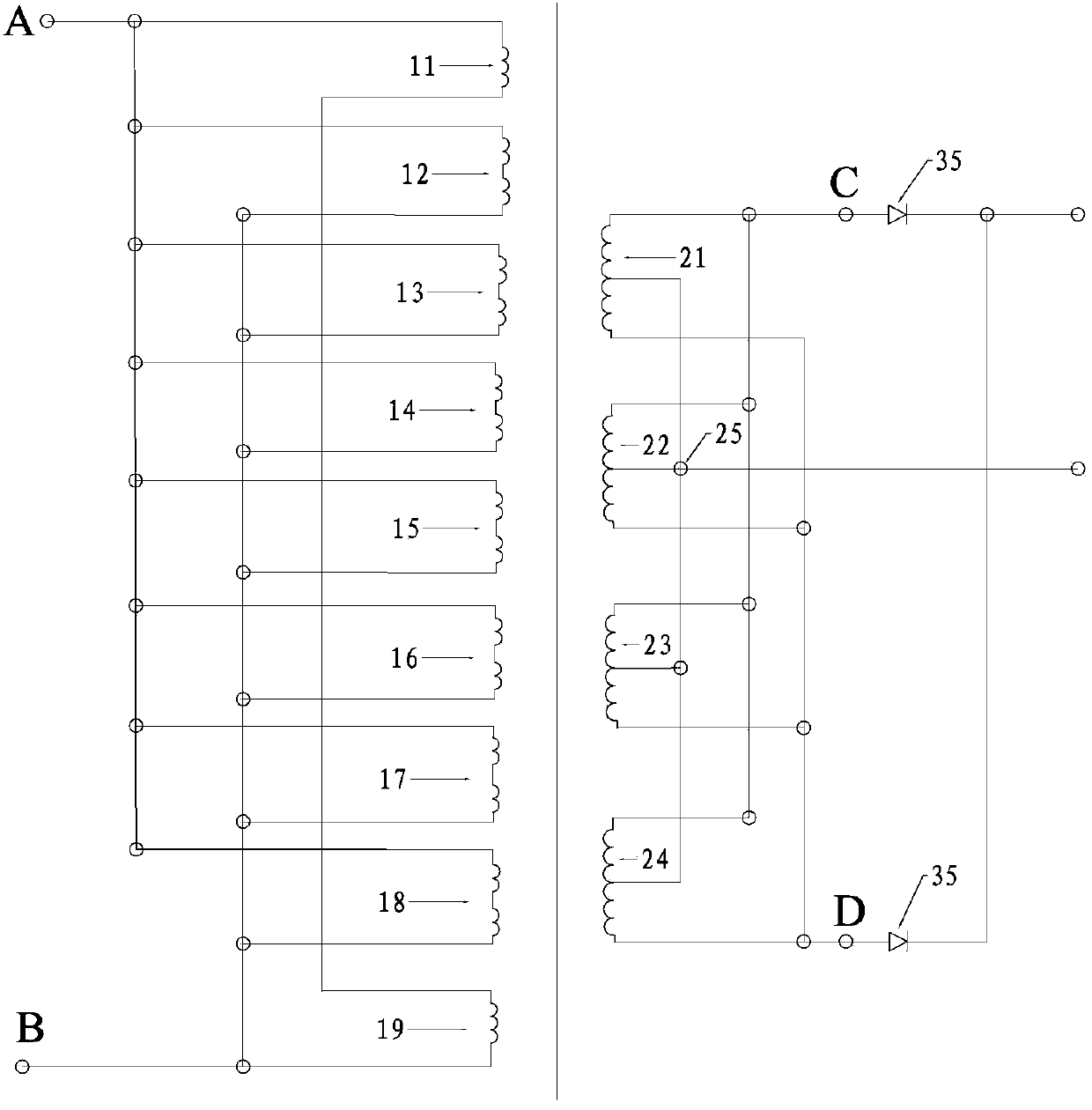

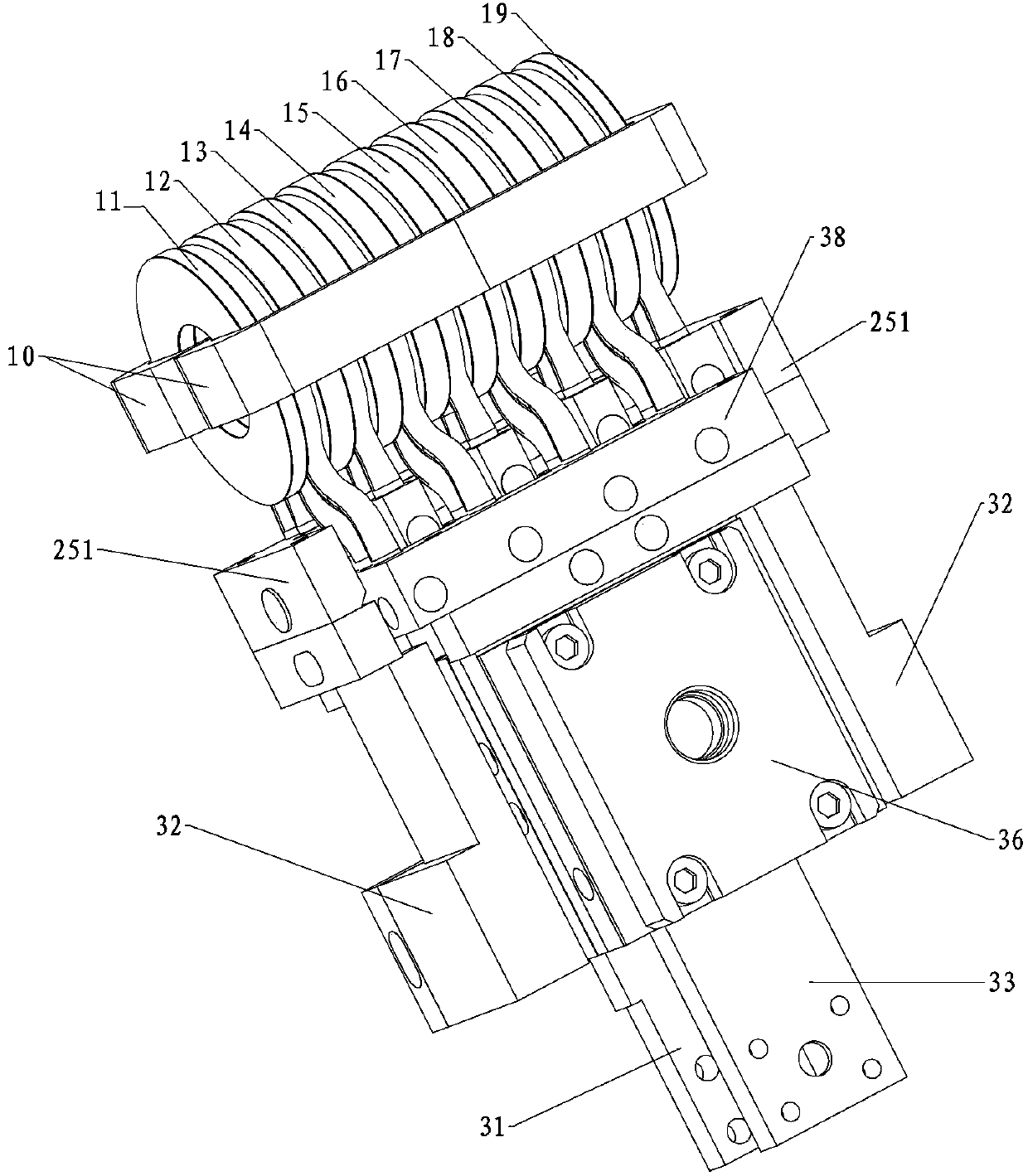

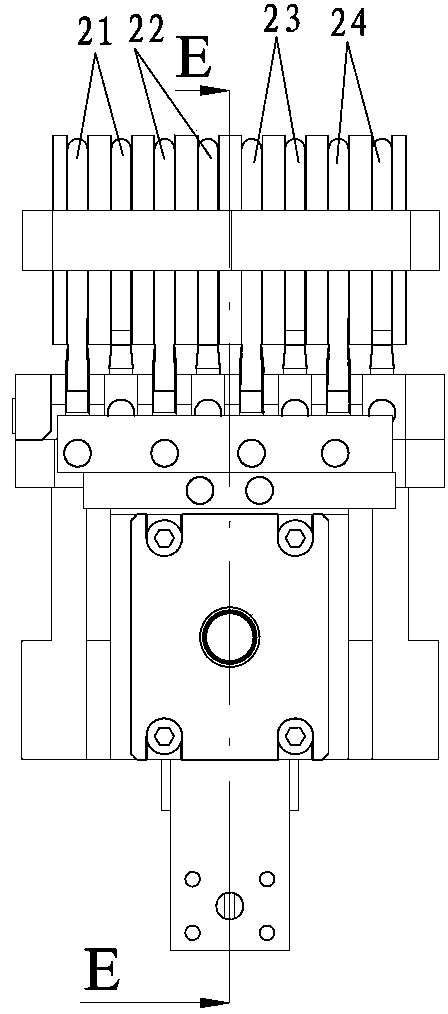

[0022] The medium and high frequency transformer of this embodiment is composed of two parts, the main transformer and the rectifier radiator, which can be separated. The iron core of the main transformer is composed of two pairs of CD-type nanocrystalline materials, the primary winding is composed of seven sets of primary wire wraps and two sets of primary small wire wraps connected in parallel, and the secondary winding is made of four sets of full-wave rectified water-through copper tubes. As a result, the rectifier radiator is mainly composed of two high-frequency planar diodes and a cooling water channel.

[0023] Refer to attached figure 1 , figure 2 As shown, the main transformer includes two iron cores 10 of CD-type nanocrystalline material, a primary winding and a secondary winding, and the primary w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com