Air energy high-speed helicopter

A helicopter and air energy technology, applied in the field of aircraft, can solve the problems of large wind resistance of fixed wings, slow helicopter speed and high cost, and achieve the effect of reducing wing tip load, fast helicopter speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

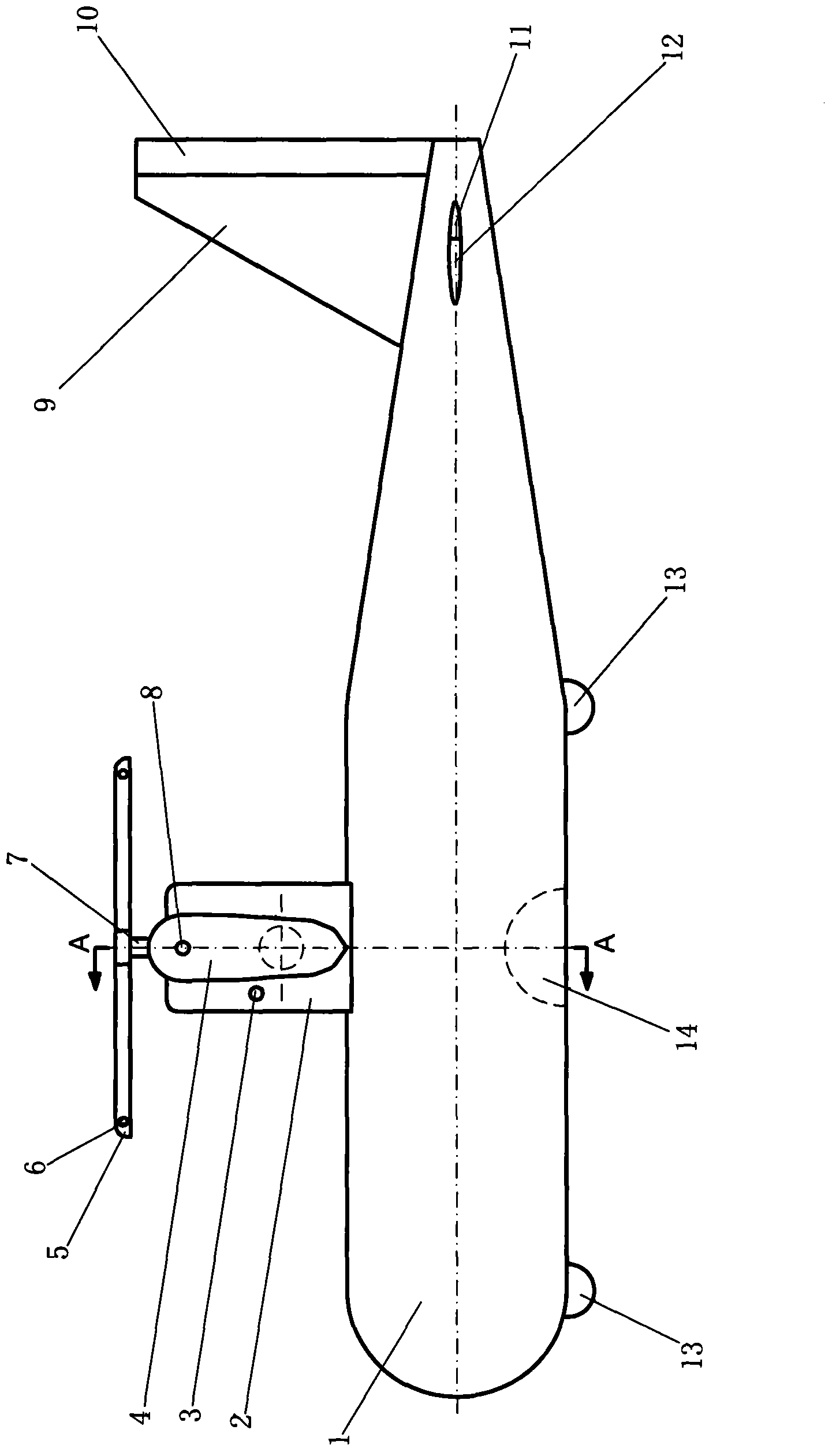

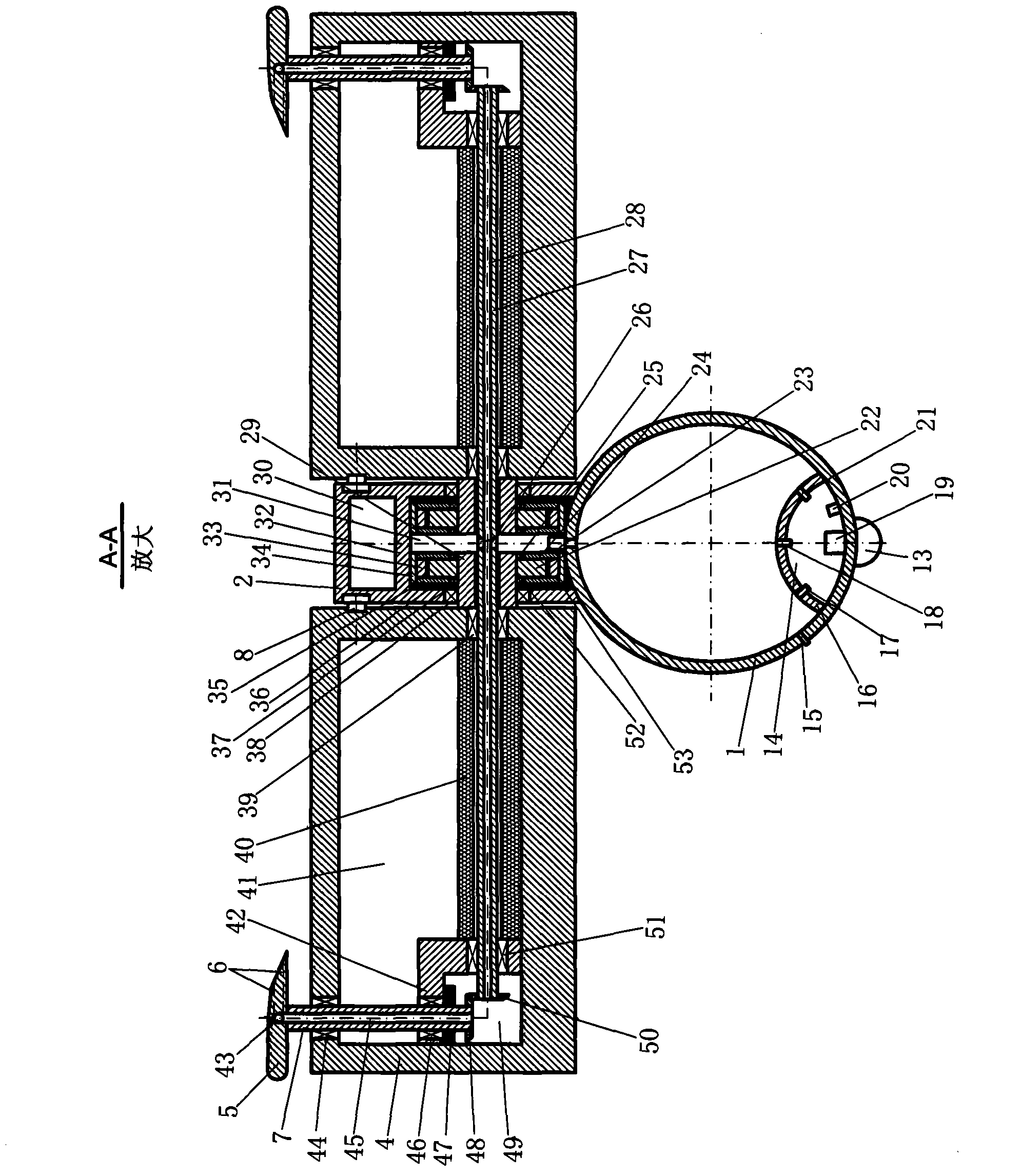

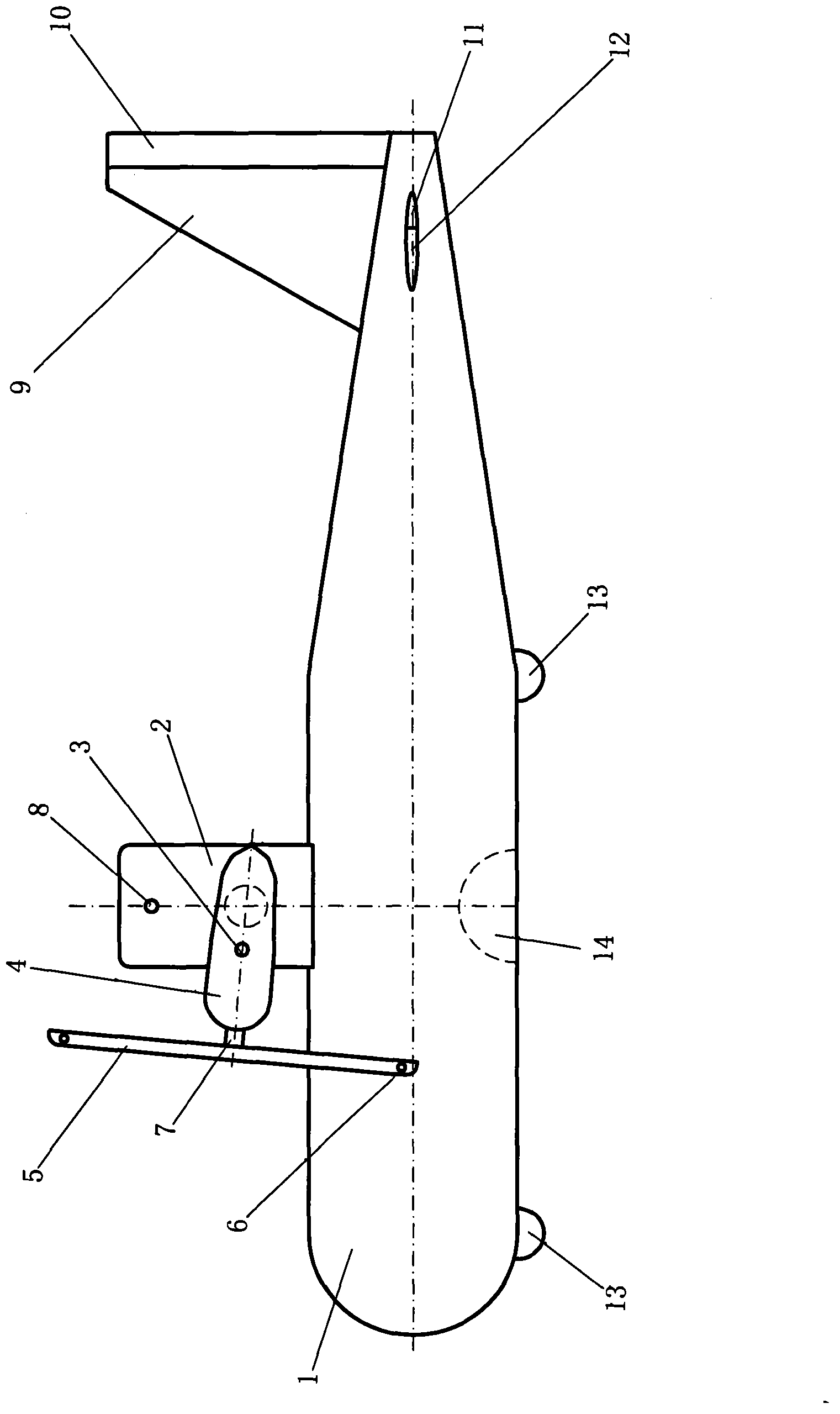

[0026] Such as figure 1 figure 2 Show. The fuselage 1 is made into a streamlined airtight shell. A compartment 14 is separated by a partition 16 in the lower part of the fuselage 1, and the partition 16 is sealed and connected with the fuselage 1. The air pressure sensor 17, the temperature sensor 18, and the humidity sensor 21 respectively penetrate the partition plate 16 and are hermetically connected with it. Storage battery 19, controller 20, instruments and meters (not shown in the figure) are arranged in the cabin 14. The air pressure sensor 17 , the temperature sensor 18 , the humidity sensor 21 , the instruments and meters, and the storage battery 19 are all connected to the controller 20 . Legs 13 are arranged at the bottom of the fuselage 1 . Air-filling valve 15 is set on fuselage 1 . The junction box 2 is vertically connected to the upper part of the fuselage 1. The first cavity 30 is separated by a partition plate 32 in the upper part of the junction box 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com