Scribing wheel, and method for manufacturing the same

A manufacturing method and scoring wheel technology, applied to other manufacturing equipment/tools, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of large influence, large deviation of the grinding start point, and reduced strength of the end surface of the brittle material substrate. Achieve the effect of easy manufacturing and easy groove processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of a scoring wheel and its manufacturing method according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

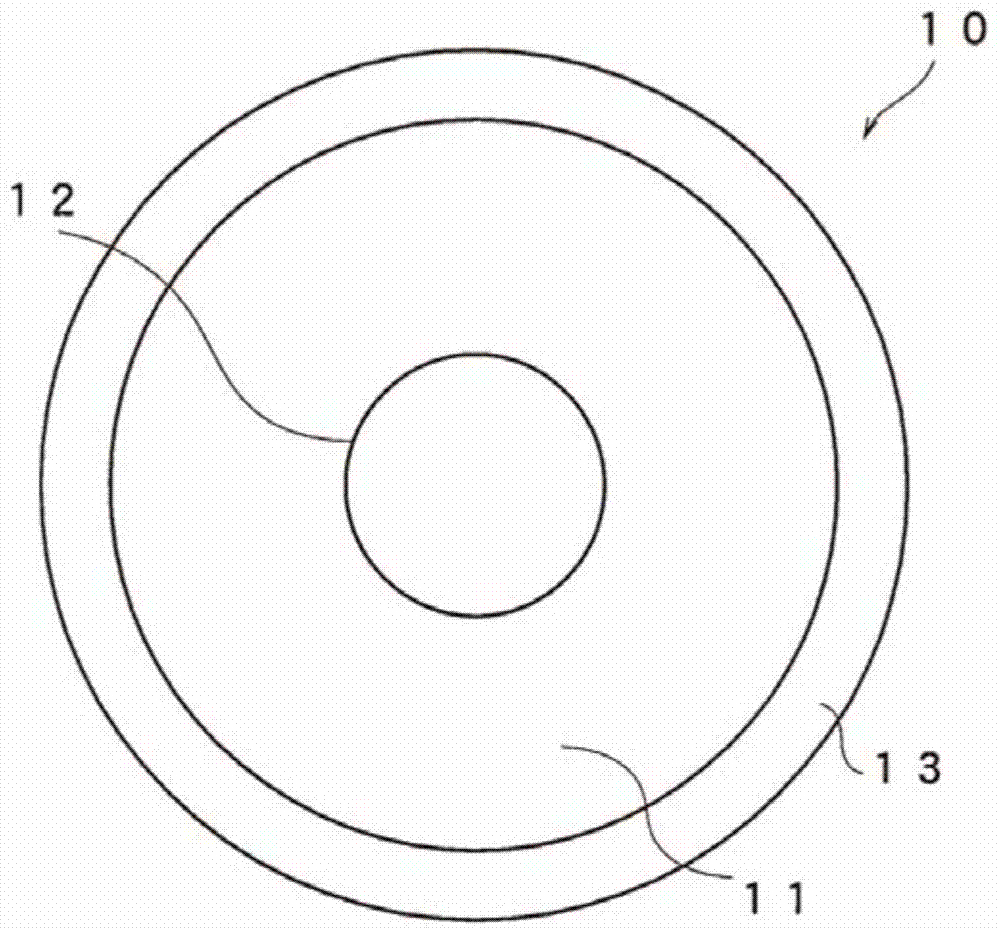

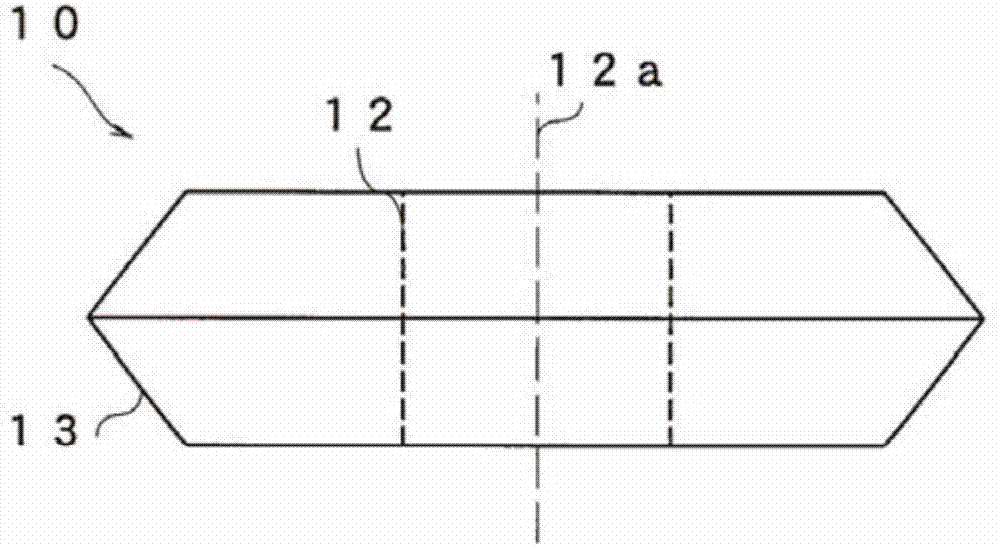

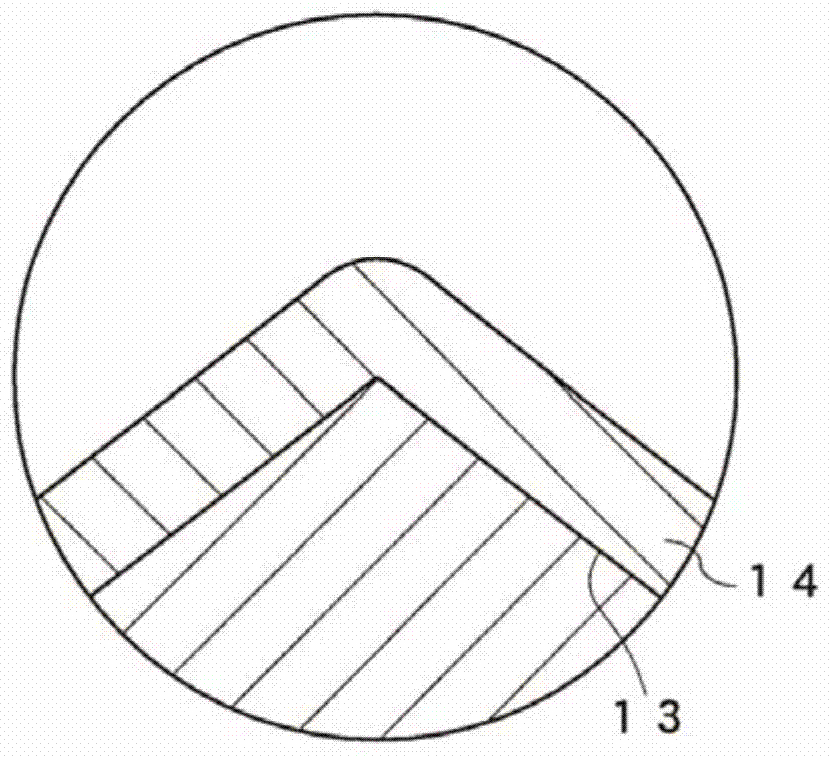

[0036] Figure 1A It is a front view of the scoring wheel of the embodiment of the present invention, Figure 1B is its side view. When manufacturing a scoring wheel, for example, first, if Figure 1A As shown, a through hole 12 serving as a shaft hole is formed in the center of a circular plate 11 serving as a base material of a scribing wheel made of cemented carbide or the like. Next, a shaft (shaft) such as a motor not shown in the figure is communicated with the through hole 12, and while the central axis of the through hole 12 is used as the rotation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com